Chapter 3 Fuel Injection Equipment

_4._A_d.;;..Ju_s_t_m_e_n_t_o_f_F_u_e_l_l_n_Je_c_t_io_n_P_u_m

...

p_an_d_G_o_v_e_r_n_or

______________

3,4JH3(B)(C)E

(2)

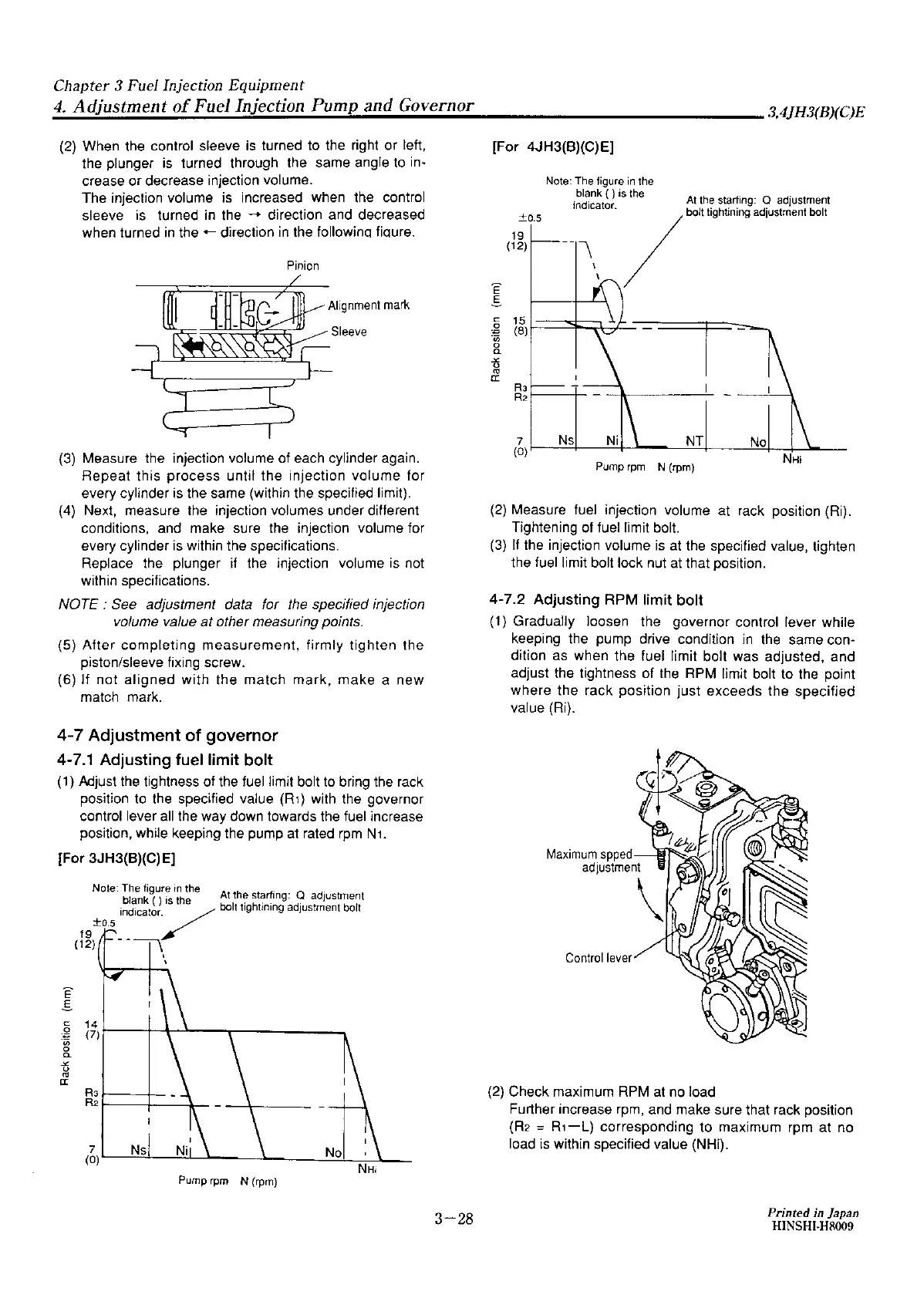

When the control sleeve

is

turned to the right or left,

the plunger

is

turned through the same angle to in-

crease or decrease injection volume.

The injection volume is increased when the control

sleeve

is

turned

in

the

-.

direction and decreased

when turned

in

the+-

direction

in

the followinq fioure.

Pinion

Alignment

mark

Sleeve

(3) Measure the injection volume of each cylinder again.

Repeat this process until the injection volume for

every cylinder

is

the same (within the specified limit).

(4) Next, measure the injection volumes under different

conditions, and make sure the injection volume for

every cylinder

is

within the specifications.

Replace the plunger if the injection volume

is

not

within specifications.

NOTE:

See adjustment data for

the

specified injection

volume value at other measuring points.

(5)

After

completing

measurement, firmly tighten the

piston/sleeve fixing screw.

(6) If not

aligned

with the match mark,

make

a

new

match mark.

4-7 Adjustment

of

governor

4-7.1 Adjusting fuel limit

bolt

(1)

Mjust

the

tightness of the fuel limit bolt to bring

the

rack

position to the specified value

(R1)

with the governor

control lever

all

the way down towards

the

fuel increase

position, while keeping the pump at rated

rpm

N1.

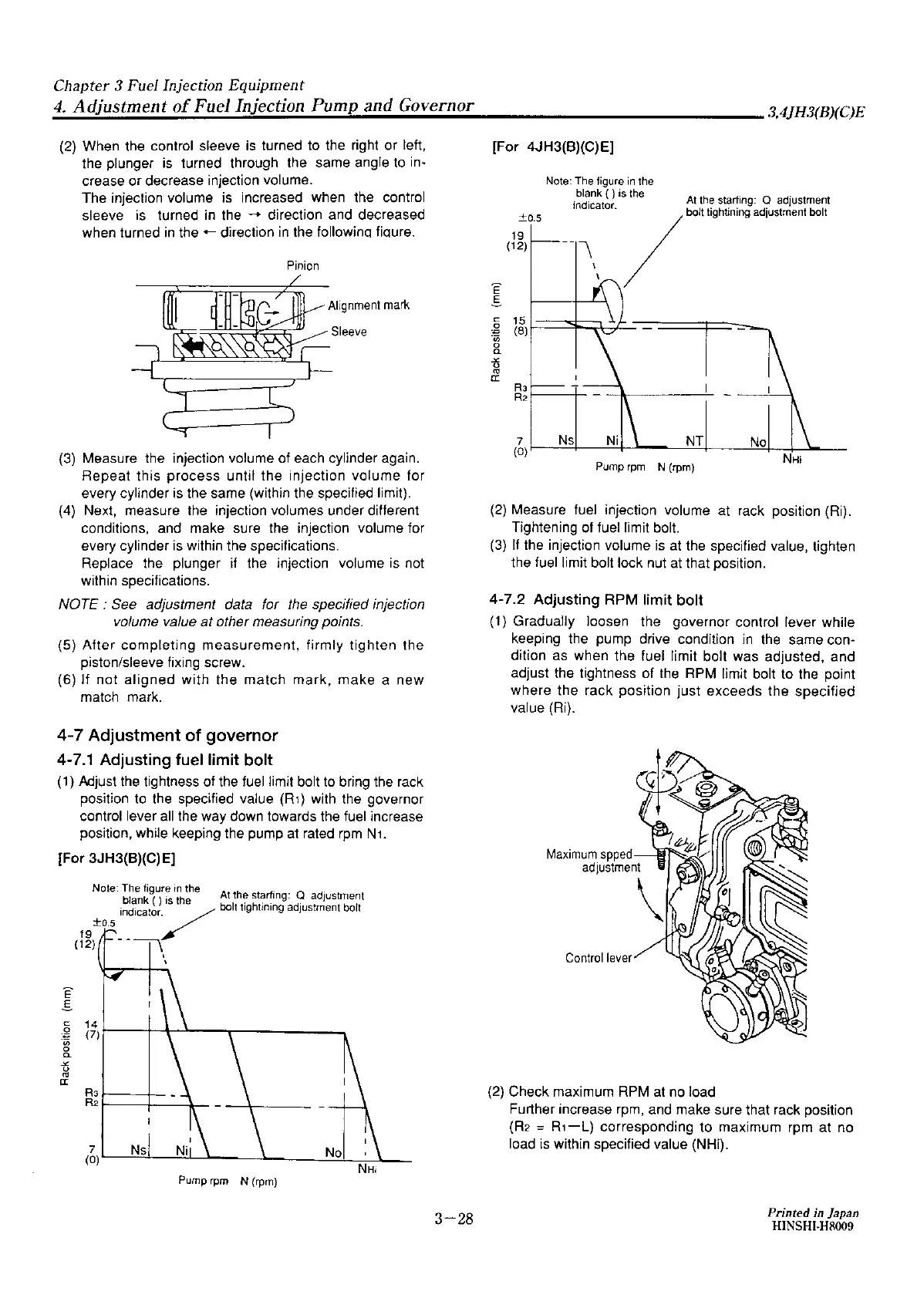

[For 3JH3(B)(C)E]

E

.s

C

.g

·;;;

g_

-"'

0

fO

a:

Note: The figure

in

the , .

blank ( )

is

the

At

!he star/mg: Q adIustment

19

indicator/

bolt

t1gh1m1ng

ad1ustment bolt

±0,5

(12)

-

----n

14

(7)

R3

R2

Pump rpm N (rpm)

3-28

[For 4JH3(B)(C)E]

E

E

C

0

.:;

·;;;

0

a.

-"'

0

fO

er.

±0.5

19

(12)

15

(8)

RJ

R2

Note: The figure

in

the

blank ( )

IS !he

mdicator

At

the starling· Q adJustment

--

\

· / bolt tighllning adjustment bolt

Pump rpm

N (rpm)

(2) Measure fuel injection volume at rack position (Ri).

Tightening of fuel limit bolt.

(3)

If

the injection volume

is

at

the specified value, tighten

the fuel limit bolt lock nut

at

that position.

4-7.2 Adjusting RPM limit bolt

(1) Gradually loosen the governor control lever while

keeping the pump drive condition

in

the same con-

dition

as

when the fuel limit bolt was adjusted, and

adjust the tightness of

the

RPM limit bolt to the point

where the rack position just exceeds the specified

value (Ri).

Maximum

spped

adjuslme

Control

lever

(2)

Check maximum RPM at no load

Further increase rpm, and make sure that rack position

(R2

=

R1-L}

corresponding to maximum rpm at no

load

is

within specified value (NHi).

Printed in Japan

HINSHI-H8009

Loading...

Loading...