Chapter 3 Fuel Injection Equipment

~4~.A~d~iu~s~t=m~e~.n~t~o~f~F~u~e~l~In~1.e~ct~fu~n~P.u_m~p;....;.a~nd_._G_o_v_e_rn_o_r

______________

~4JH~BXC)E

4-

7 .3

Adjusting

idling

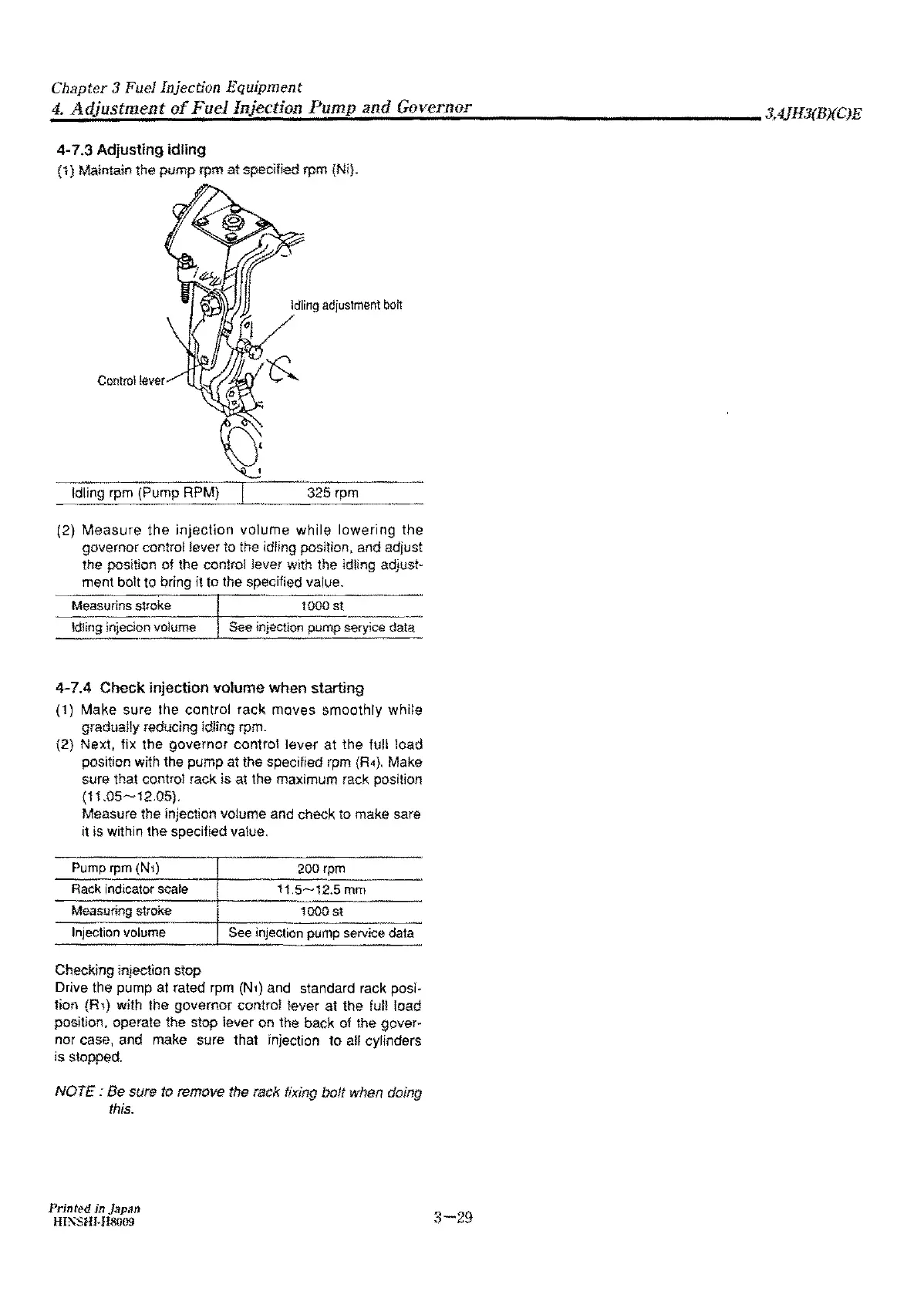

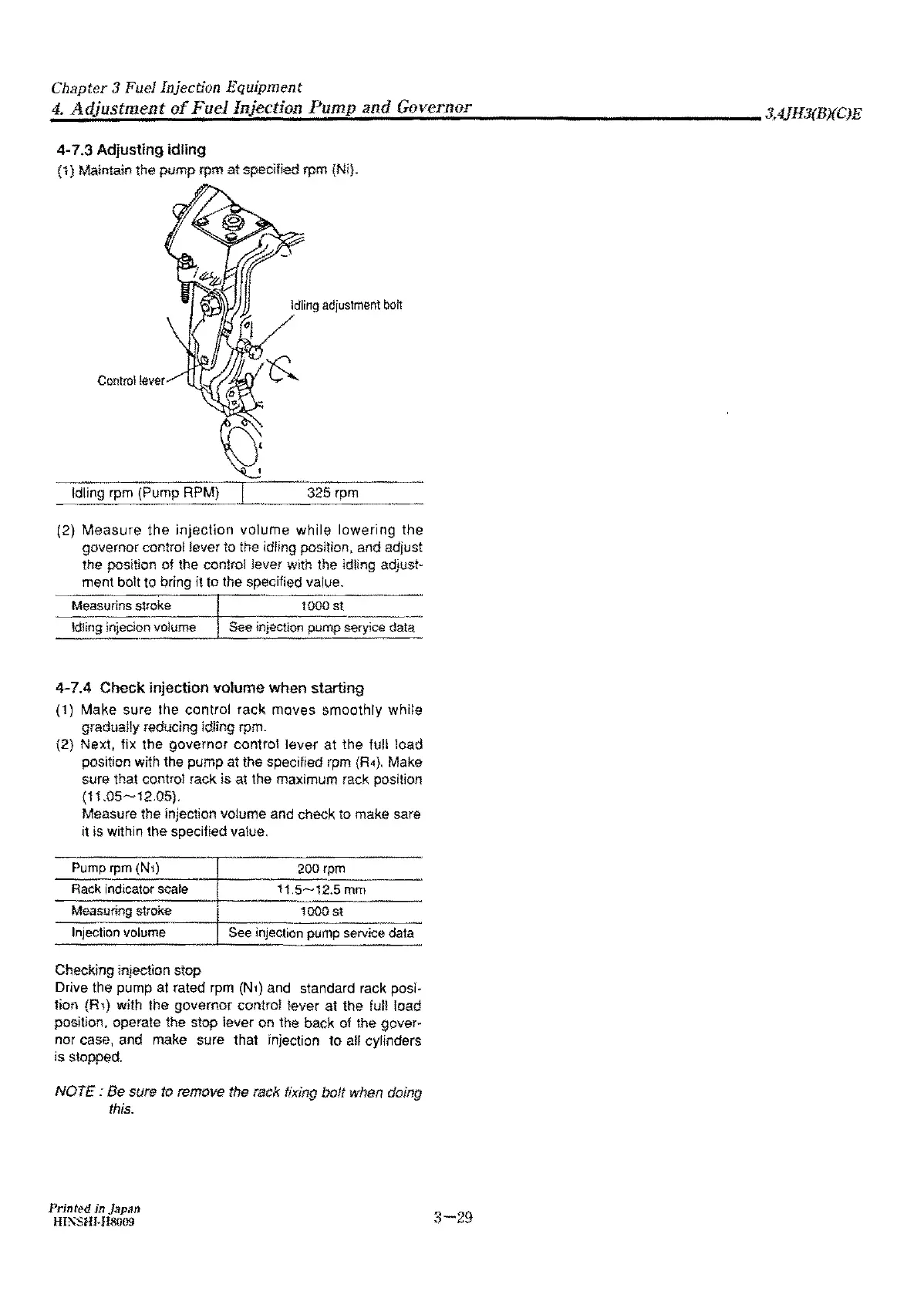

{1} Maintain the

pump

rpm

at

speclfled rpm {Ni}.

Control

!-ever

Idling rpm {Pump RPM} 325 rpm

(2) Measure the

injection

volume

while

lowering

the

governor control lever to the idling position, and adjust

the position

of

the con!rol lever with the idling adjust-

ment bolt to bring

it

to

the specified value.

Measurins

~roke

1000

st

Idling injecion volume See injection pump seryice data

4-7.4 Check injection volume when starting

( 1) Make sure the control

rack

moves

smoothly

white

gradually reducing idling rpm.

(2} Next, fix the

governor

control

lever

at

the full load

position with the pump at the specified rpm

{R4},

Make

sure that control rack

is

a1

the maximum rack position

(11.05~12.05}.

Measure the injection volume and check to make sare

it

is within the specified value.

Pump rpm (N1)

200 rpm

Rack

indicator scale

115~12.5

mm

Measuring stroke

1000

st

Injection volume

See injection

pump

seNice

data

Checking injection stop

Drive the pump at rated rpm

(N1)

and standard rack posi•

fion

(R1) with the governor control lever at the full load

position, operate the stop lever on the back of the gover•

nor case, and make sure that injection

to

afl cylinders

is

stopped.

NOTE:

Be sure

to

remove the rack fixing bolt when doing

this.

Printed in

Japan

HI.1\SHJ.ll8009

3-29

Loading...

Loading...