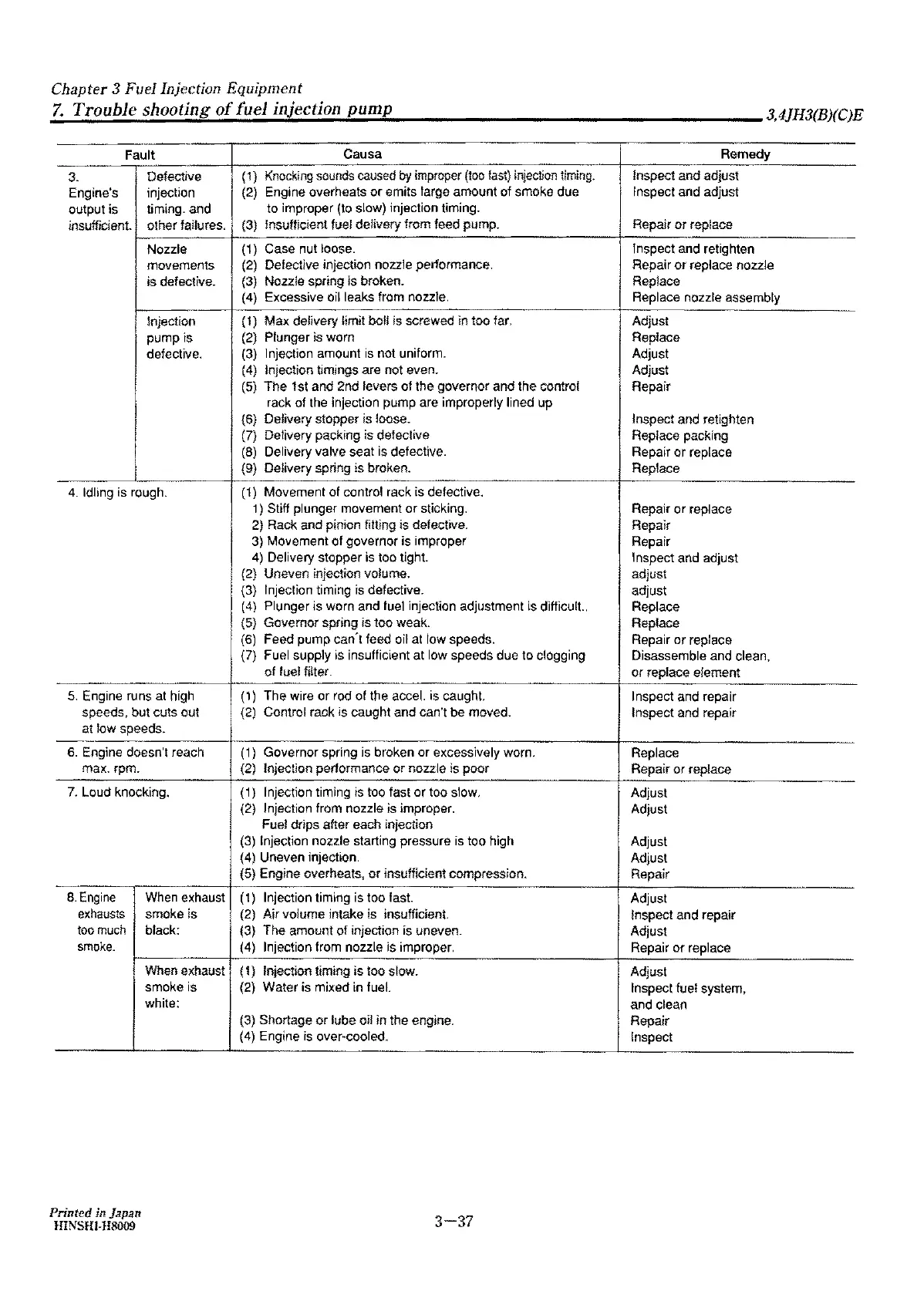

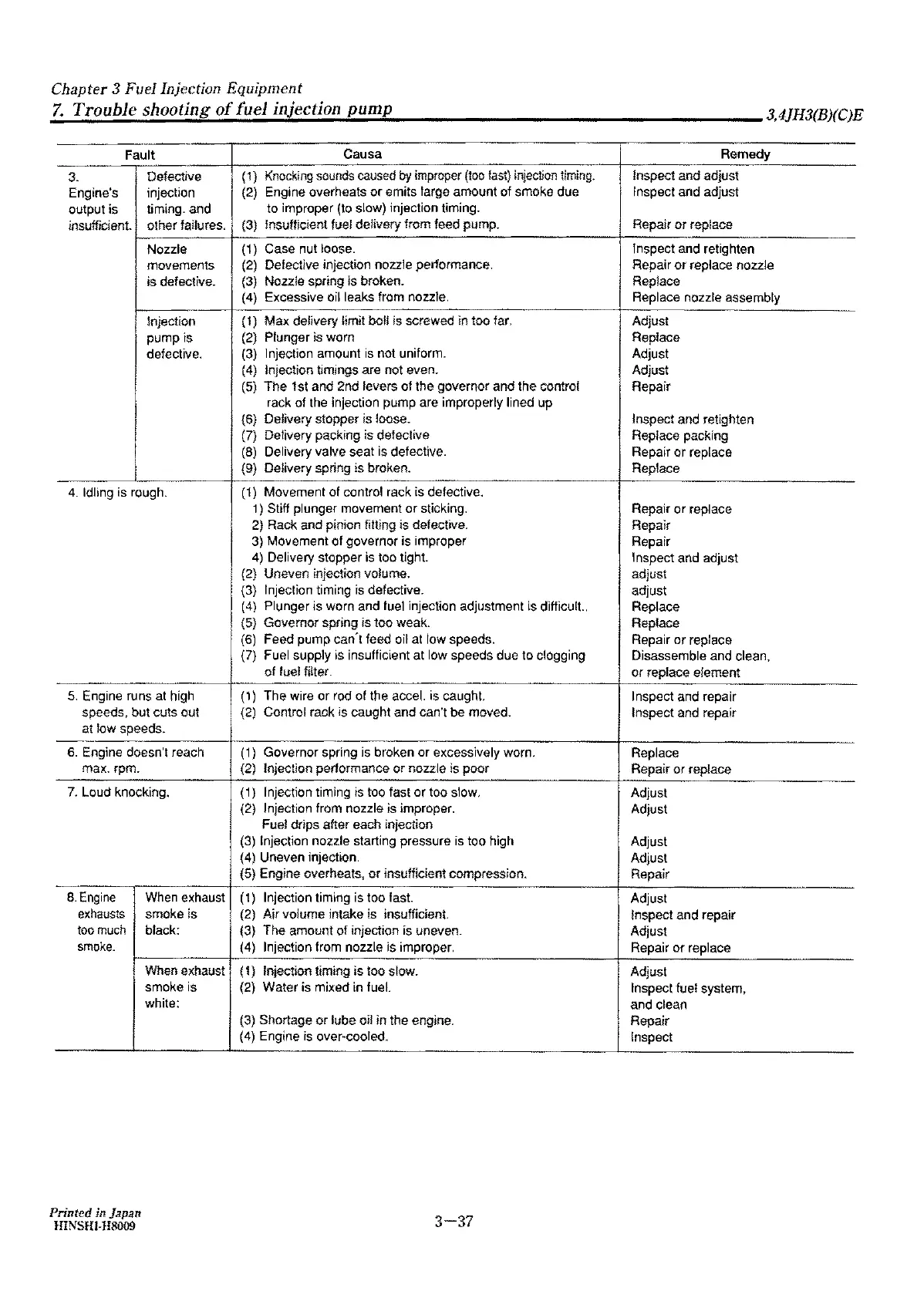

Chapter 3 Fuel Injection Equipment

.;.7.;.....;;;T.;;.r.;.o.;;;;ub;;;.;1;.;.e..;s;.;;.h;.;.o..;.o

...

ti

...

ng~o-f_fi_ue_l_1_·n

...

ie_c_t1_·0_n

.....

P

....

u_m_p

__________________

3,4JH3(B)(CJE

Fault

3.

Defective

Engine's injection

output ls

liming. and

insufficient.

other failures.

Nozzle

movements

is defective.

lnjection

pump is

defective.

4.

Idling is rough.

5.

Engine runs at high

speeds, but cuts out

at !ow speeds.

6. Engine doesn't reach

max. rpm.

7.

Loud knocking.

8.

Engine

exhausts

too

much

smoke.

Printed

in

Japan

HINSHI-H8009

When exhaust

smoke is

black:

When exhaust

smoke is

white:

Causa

Remedy

(1)

Knocki09 sounds caused by improper

{too

fast)

injection timing.

Inspect and adjust

(2}

Engine overheats

or

emits large amount of smoke due Inspect and adjust

to improper (to slow) injection timing.

(3)

Insufficient fuel delivery from feed pump.

Repair

or

replace

(1)

Case nut loose.

Inspect and retighten

(2)

Defective injection nozzle performance.

Repair

or

replace nozzle

(3)

Nozzle spring is broken.

Replace

{4)

Excessive oil leaks from nozzle. Replace nozzfe assembly

(1)

Max

delivery limit boll is screwed in too far. Adjust

(2)

Plunger is worn

Replace

(3)

Injection amount

is

not uniform. Adjust

(4} Injection timings are not even.

Adjust

(5)

The

1st and 2nd levers

of

the governor and

the

control

Repair

rack of the injection pump are improperly lined up

(6}

Delivery stopper is loose.

Inspect and retighten

(7}

Delivery packing is defective Replace packing

(8)

Delivery valve seat is defective. Repair or replace

(9)

Delivery spring is broken.

Replace

(1) Movement of control rack is defective.

1) Stiff plunger movement

or

sticking. Repair or replace

2) Rack and pinion lilting is defective. Repair

3) Movement

of

governor is improper Repair

4) Delivery stopper is too tight. Inspect and adjust

(2) Uneven injection volume. adjust

(3) Injection timing

is

defective. adjust

(4)

Plunger is worn and fuel injection adjustment is difficult..

Replace

(5) Governor spring is too weak. Replace

(6) Feed pump can't feed oil at low speeds,

Repair

or

replace-

(7) Fuel supply is insufficient

at

low speeds due to clogging

Disassemble and clean,

of fuel filter.

or

replace element

(1) The wire or rod of the accel. is

caught

Inspect and repair

(2)

Control rack is caught and can't be moved,

Inspect and repair

(,)

Governor spring is broken or excessively worn,

Replace

(2) Injection performance

or

nozzle is poor Repair

or

replace

( 1)

Injection timing is too fast or too slow,

Adjust

(2) Injection from nozzle is improper.

Adjust

Fuel drips after each injection

(3)

Injection nozzle starting pressure is too high

Adjust

{4) Uneven injection.

Adjust

(5} Engine overheats,

or

insufficient compression.

Repair

(1) Injection timing is too last.

Adjust

(2) Air volume intake is insufficient Inspect and repair

{3} The amount of injection is uneven. Adjust

(4) Injection from nozzle is improper. Repair or replace

(1)

Injection timing is too slow.

Adjust

{2}

Water is mixed in fuel.

Inspect fuel system,

and clean

(3) Shortage

or

lube oil in the engine. Repair

(4) Engine

is

over-cooled.

Inspect

3-37

Loading...

Loading...