Page 3-16 110XiIIIPlus Maintenance Manual 13185L-002 Rev. A 1/24/06

Section 3 Troubleshooting

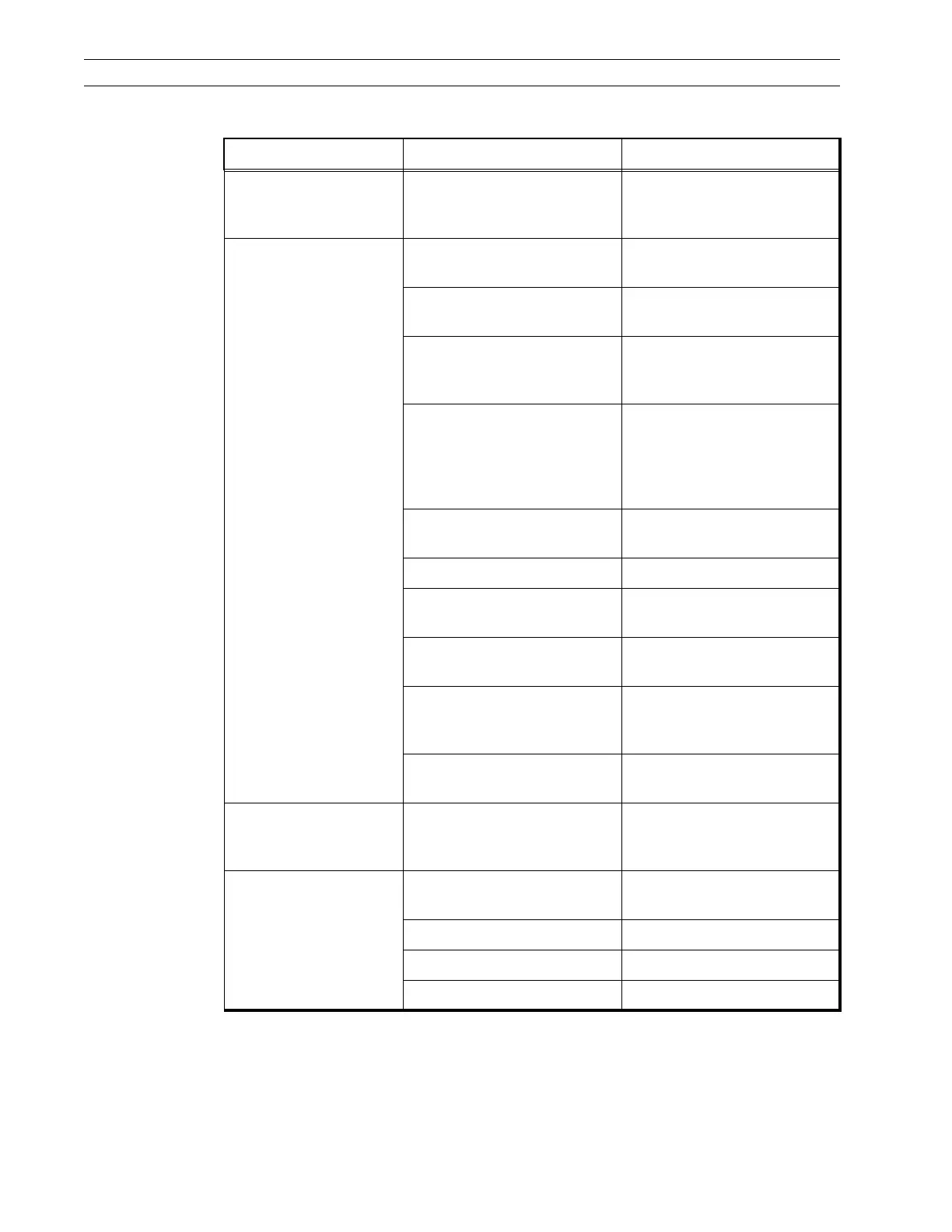

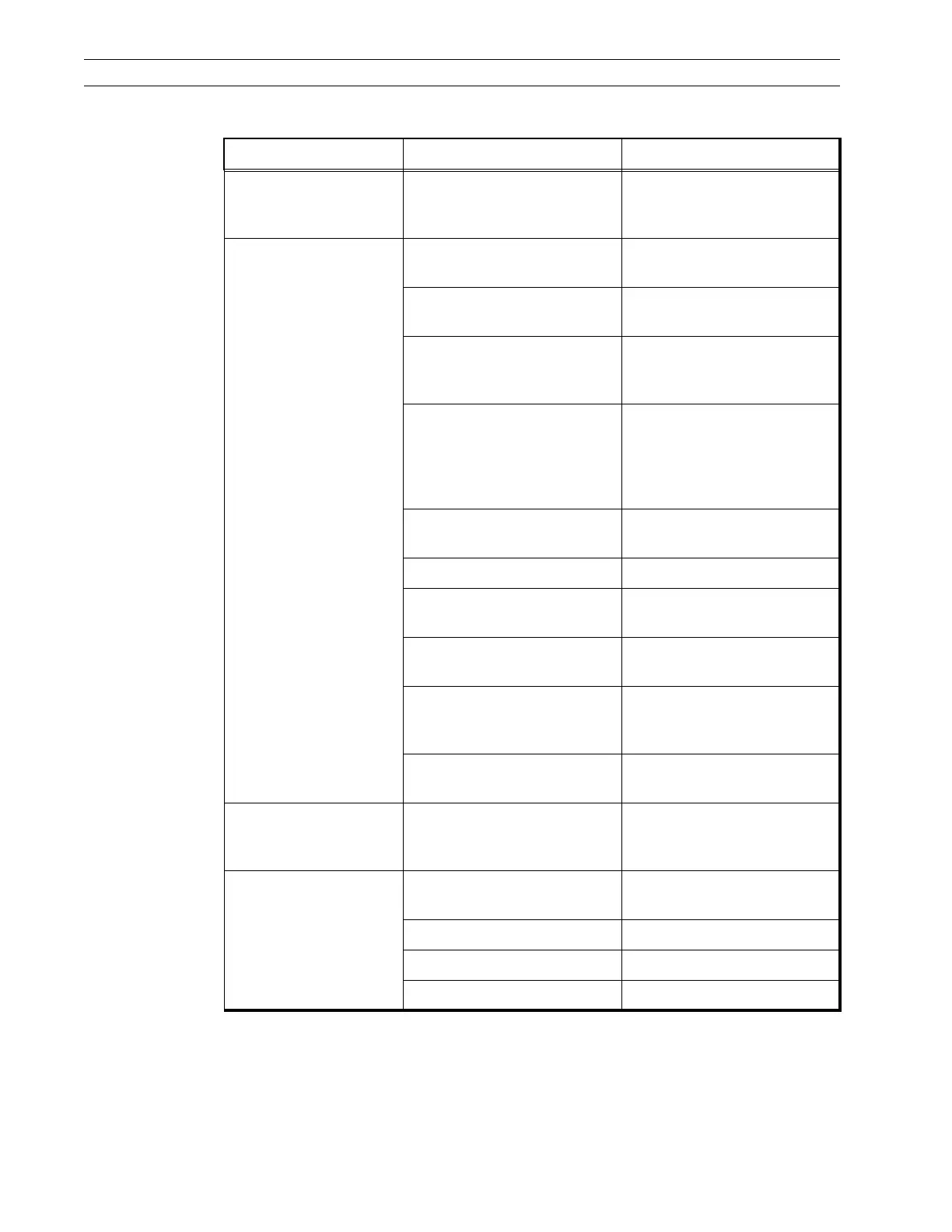

Fine gray lines on blank

labels at angles.

Wrinkled ribbon. Refer to Wrinkled Ribbon

Symptom on page 3-16 of this

table.

Wrinkled ribbon Ribbon fed through machine

incorrectly.

Load ribbon correctly.

Ribbon supply spindle tension

needs adjusting.

Perform adjustments.

Incorrect burn temperature. Set burn temperature to

lowest setting possible for

good print quality.

Incorrect printhead pressure

or balance.

Set pressure to minimum

needed. Refer to printhead

balance adjustment and

printhead pressure

adjustment procedures.

Media not feeding properly;

walking from side to side.

Make sure media is snug by

adjusting media guide.

Strip plate needs adjusting. Perform adjustments.

Printhead needs realigning

with platen roller.

Perform adjustments.

Ribbon take-up spindle

tension needs adjusting.

Perform adjustments.

Three-point mount for ribbon

supply spindle needs

adjusting.

Perform adjustments.

Ribbon supply core slipping;

spindle blades need adjusting.

Perform adjustments.

Light printing or no

printing on left or right

side of label.

Printhead needs balancing. Adjust balance. See printhead

balance adjustment

procedures.

Misregistration or

skipped labels.

Improper sensor type

selected.

Perform media sensor

adjustments.

Misadjusted media sensors. Calibrate printer.

Improper spindle tensions. Perform spindle adjustments.

Improper ZPL format. Correct ZPL format.

Table 3-3. Basic Troubleshooting (Continued)

Symptom Diagnosis Action

Loading...

Loading...