■ Recommended annual maintenance actions by the user

DescriptionAction

Quality of supply voltageP

Spare partsI

Capacitor reforming, spare modules and spare Capacitors (page 107)

P

Tightness of terminalsI

Dustiness, corrosion or temperatureI

Heatsink (page 103) cleaning

P

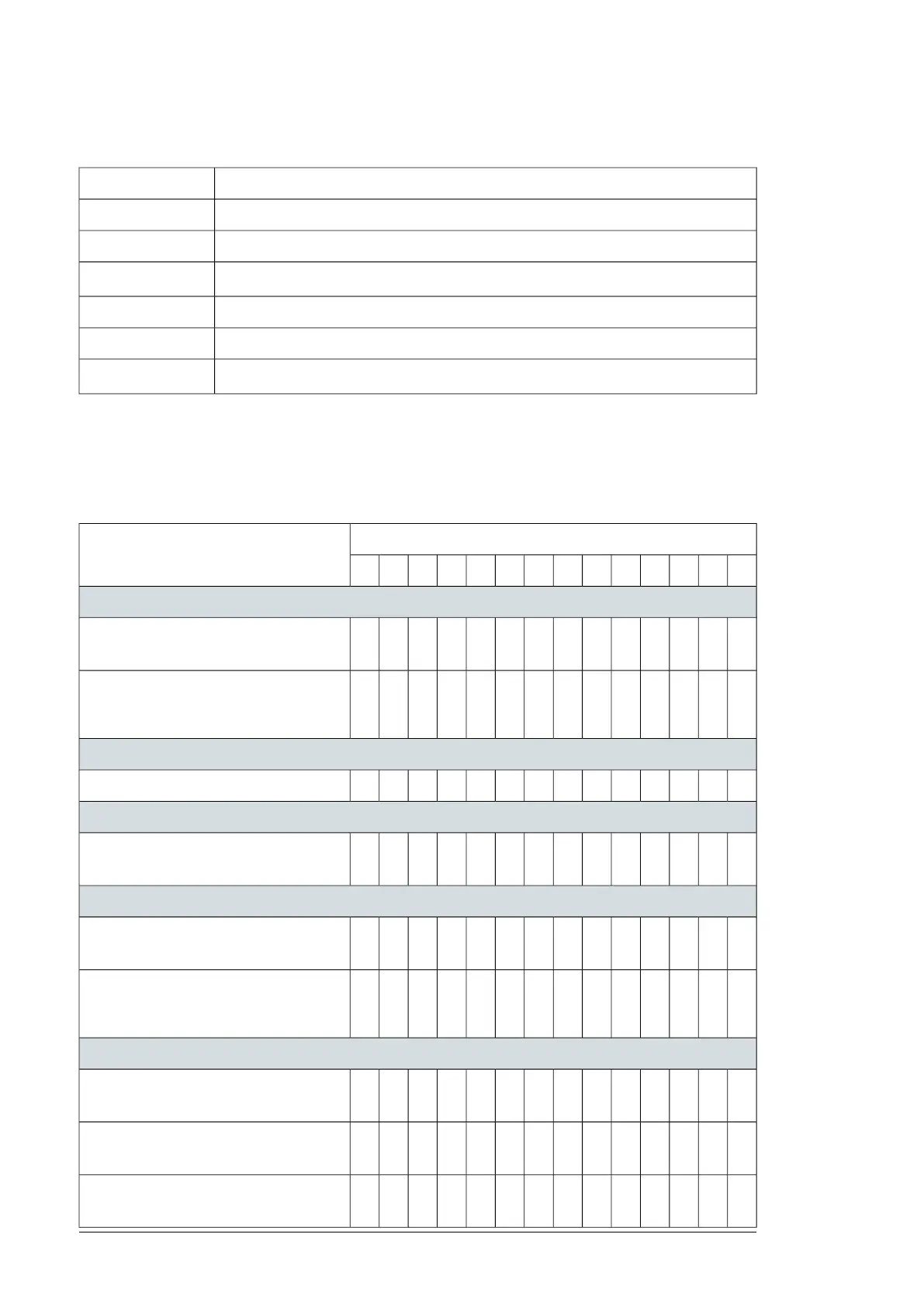

■ Recommended maintenance action by the user

The table below shows the intervals for the preventive maintenance tasks allowed for the

customer. For other maintenance tasks, consult your local ABB Service representative, or

see the complete maintenance schedule on the Internet.

Years from start-upMaintenance task/object

...1211109876543210

Cooling fans

R(R)R(R)

Main cooling fan (R0… R8). See

Fans (page 103).

(R)(R)

RRRR

Auxiliary cooling fan for circuit boards

(R6…R8). See Replacing the auxiliary

cooling fan, frames R6...R8 (page 106).

(R)(R)(R)(R)

Connections and environment

OOOOOOOOOOOOOQuality of supply voltage

Improvements

IIIIBased on product notes

(I)(I)(I)(I)

Spare parts

IIIIIIIIIIIIISpare part stock

(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)

OOOOOOOOOOOOO

Reforming of DC circuit capacitors (spare

modules and spare capacitors). See section

Capacitors (page 107).

Other tasks

IIIIIIIIIIIIIChecking tightness of cable and busbar

terminals. Tightening if needed.

(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)

IIIIIIIIIIIIIChecking ambient conditions (dustiness,

moisture, temperature)

(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)(I)

OOOOOOOOOOOOO

Cleaning the heatsink. See section Heat-

sink (page 103).

(O)(O)(O)(O)(O)(O)(O)(O)(O)(O)(O)(O)(O)

102 Maintenance and hardware diagnostics

Loading...

Loading...