■ Routing the cables

General guidelines, IEC

• Route the motor cable away from other cables. Motor cables of several drives can be

run in parallel installed next to each other.

• Install the motor cable, input power cable and control cables on separate trays.

• Avoid long parallel runs of motor cables with other cables in order to decrease

electromagnetic interference caused by the rapid changes in the drive output voltage.

• Where control cables must cross power cables, make sure they are arranged at an

angle as near to 90 degrees as possible.

• Do not run extra cables through the drive.

• Make sure that the cable trays have good electrical bonding to each other and to the

grounding electrodes. Aluminum tray systems can be used to improve local equalizing

of potential.

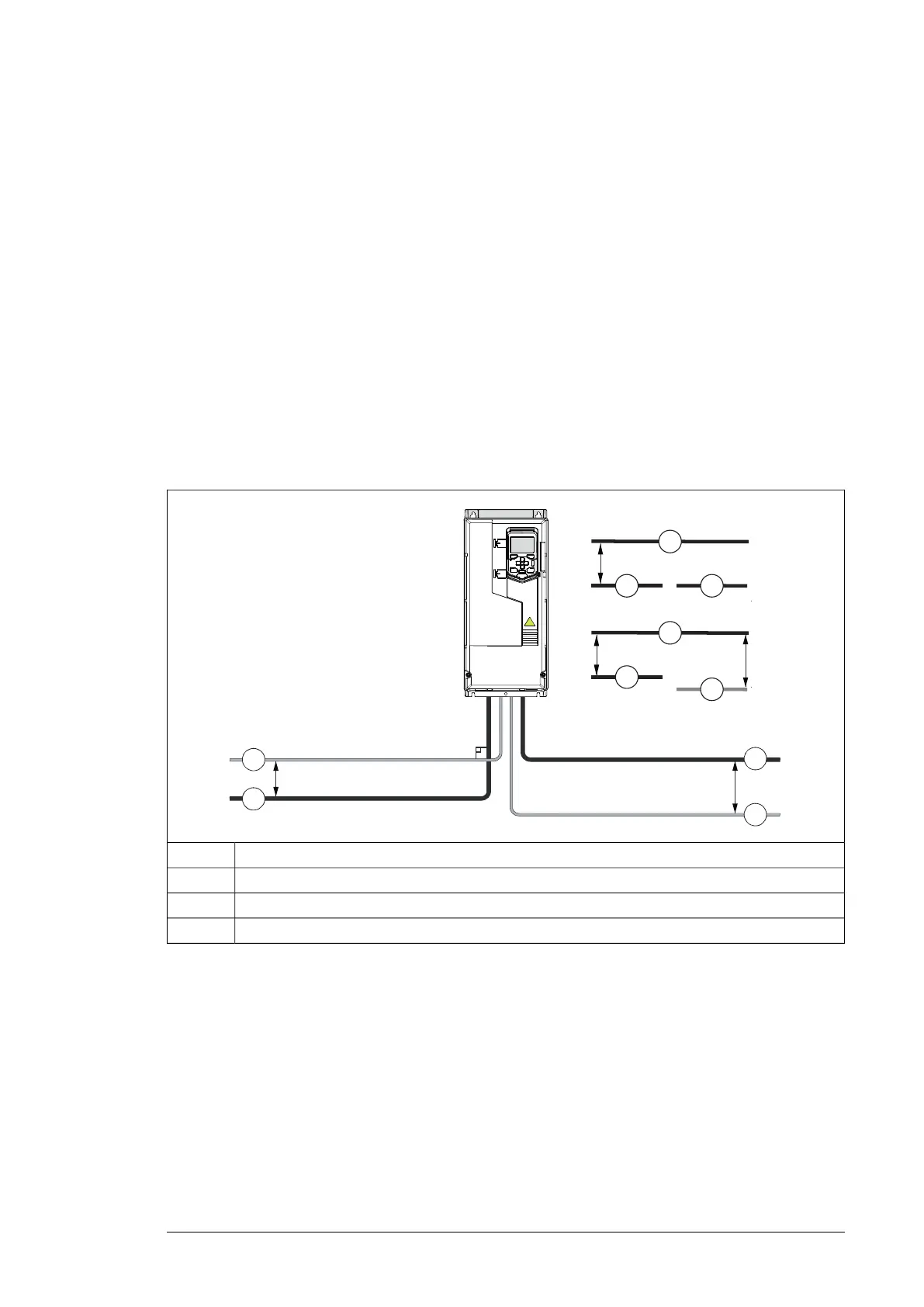

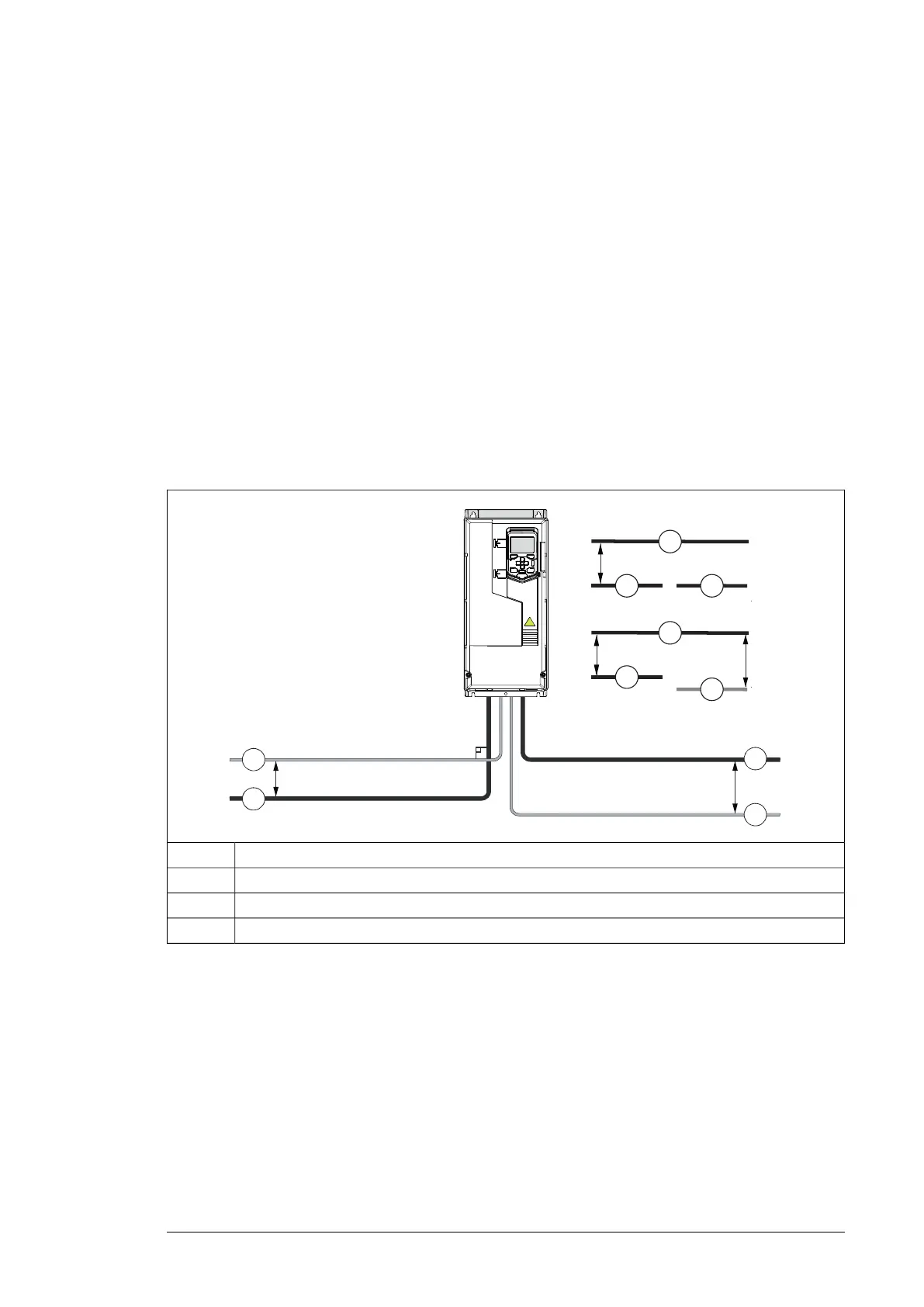

This figure illustrates the cable routing guidelines with an example drive.

min. 200 mm (8 in)

90°

*min. 500 mm (20 in)

1

2

3

3

2

1

4

min. 300 mm (12 in)

2

4

3

min. 300 mm (12 in)

*

Motor cable1

Input power cable2

Control cable3

Brake resistor or chopper cable (if any)4

Planning the electrical installation 57

Loading...

Loading...