- Frames R3…R8: 2 ms (typical), 5 ms (maximum)

• Fault detection time: Channels in different states for longer than 200 ms

• Fault reaction time: Fault detection time + 10 ms

• Indication delays:

•

STO fault indication (parameter 31.22) delay: < 500 ms

•

STO warning indication (parameter 31.22) delay: < 1000 ms

■ Abbreviations

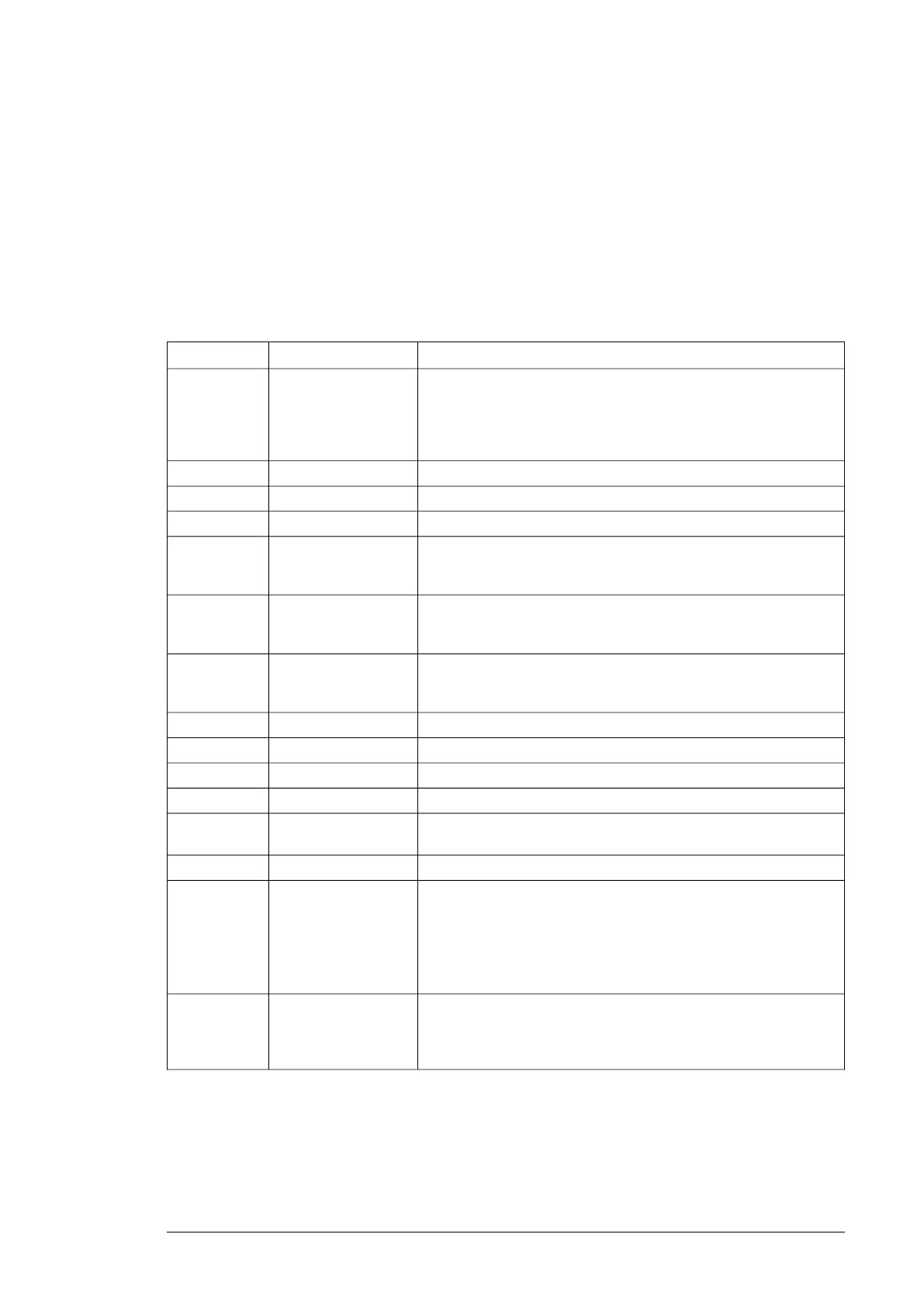

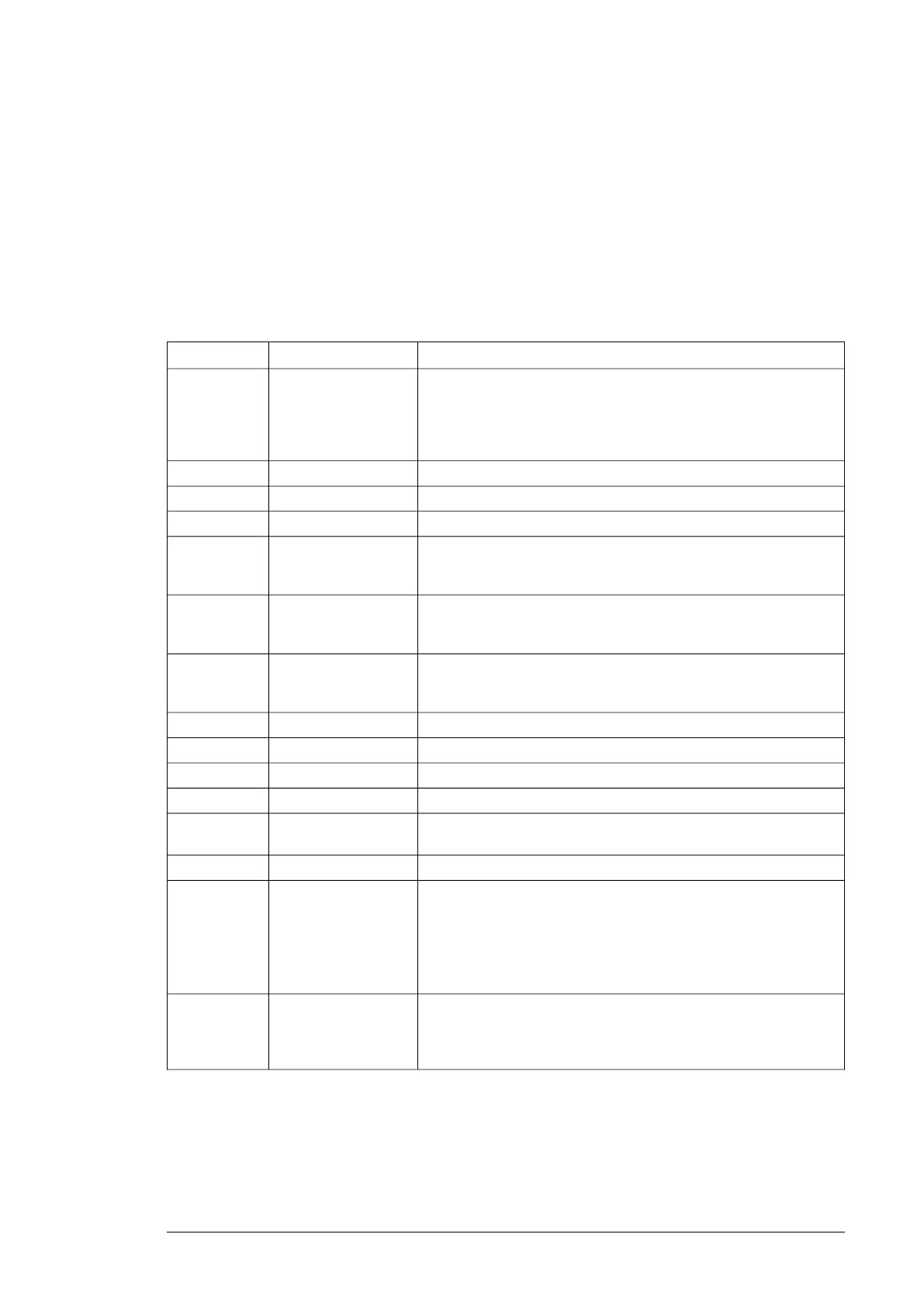

DescriptionReferenceAbbr.

Classification of the safety-related parts of a control system in respect

of their resistance to faults and their subsequent behavior in the fault

condition, and which is achieved by the structural arrangement of the

parts, fault detection and/or by their reliability. The categories are: B,

1, 2, 3 and 4.

EN ISO 13849-1Cat.

Common cause failure (%)EN ISO 13849-1CCF

Diagnostic coverageEN ISO 13849-1DC

Hardware fault toleranceIEC 61508HFT

Mean time to dangerous failure: (Total number of life units) / (Number

of dangerous, undetected failures) during a particular measurement

interval under stated conditions

EN ISO 13849-1MTTF

D

Average probability of dangerous failure on demand, that is, mean

unavailability of a safety-related system to perform the specified safety

function when a demand occurs

IEC 61508PFD

avg

Average frequency of dangerous failures per hour, that is, average

frequency of a dangerous failure of a safety related system to perform

the specified safety function over a given period of time

IEC 61508PFH

Performance level. Levels a…e correspond to SILEN ISO 13849-1PL

Systematic capabilityIEC 61508SC

Safe failure fraction (%)IEC 61508SFF

Safety integrity level (1…3)IEC 61508SIL

Maximum SIL (level 1…3) that can be claimed for a safety function

or subsystem

IEC/EN 62061SILCL

Safe torque offIEC/EN 61800-5-2STO

Proof test interval. T

1

is a parameter used to define the probabilistic

failure rate (PFH or PFD) for the safety function or subsystem. Per-

forming a proof test at a maximum interval of T

1

is required to keep

the SIL capability valid. The same interval must be followed to keep

the PL capability (EN ISO 13849) valid.

IEC 61508-6T

1

See also section Maintenance.

Mission time: the period of time covering the intended use of the safety

function/device. After the mission time elapses, the safety device must

be replaced. Note that any T

M

values given cannot be regarded as a

guarantee or warranty.

EN ISO 13849-1T

M

The Safe torque off function 161

Loading...

Loading...