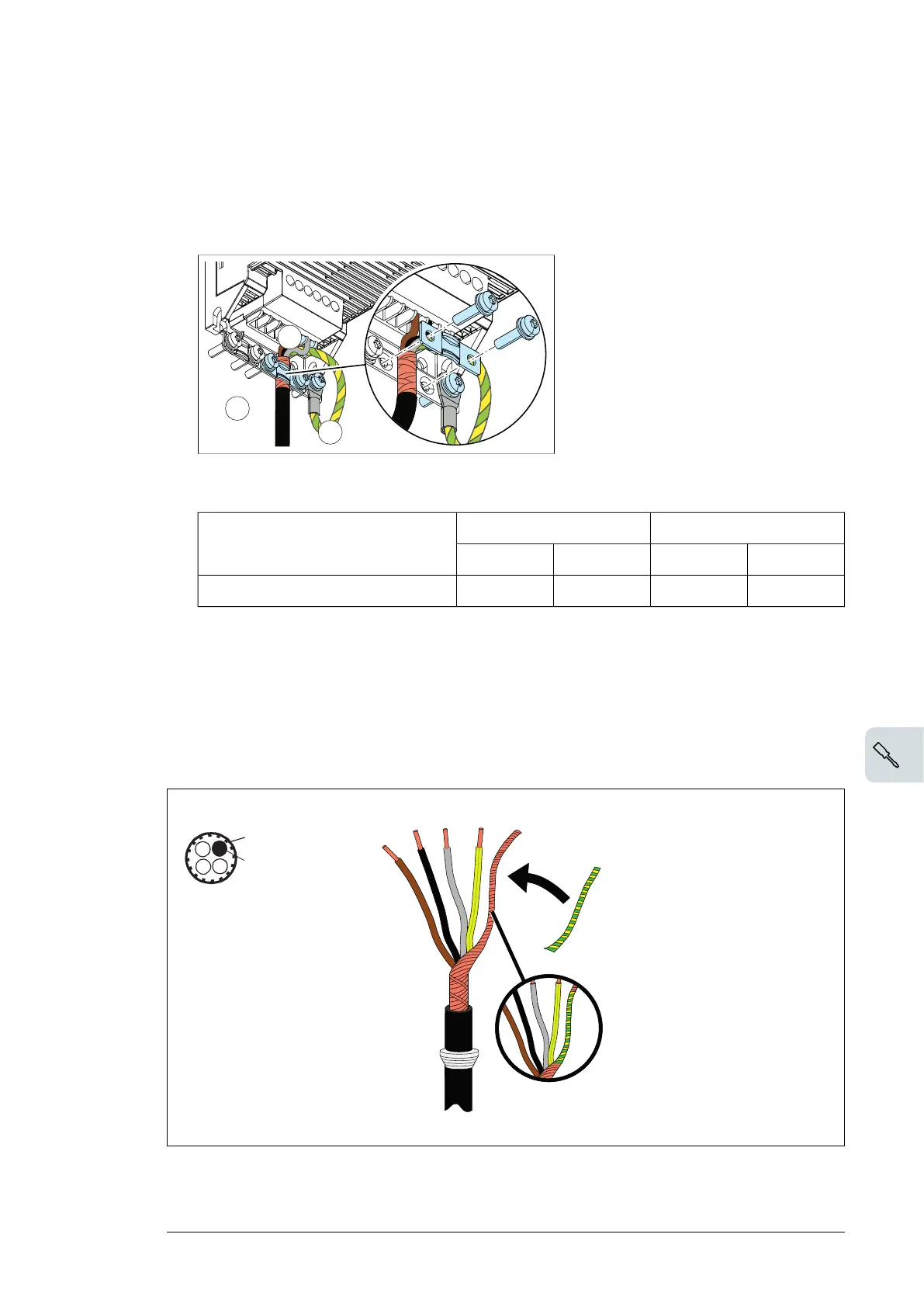

3. Connect the motor cable as follows:

• Ground the shield 360 degrees by tightening the clamp of the power cable grounding

shelf onto the stripped part of the cable (3a).

• Connect the twisted shield of the cable to the grounding terminal (3b).

• Connect the phase conductors of the cable to the terminals of T1/U, T2/V and T3/W.

Electrical installation 79

3. Connect the motor cable as follows:

• Ground the shield 360 degrees by tightening the clamp of the power cable

grounding shelf onto the stripped part of the cable (3a).

• Connect the twisted shield of the cable to the grounding terminal (3b).

• Connect the phase conductors of the cable to the terminals of T1/U, T2/V and

T3/W.

• Tighten the screws to the torque given below.

Input power cable

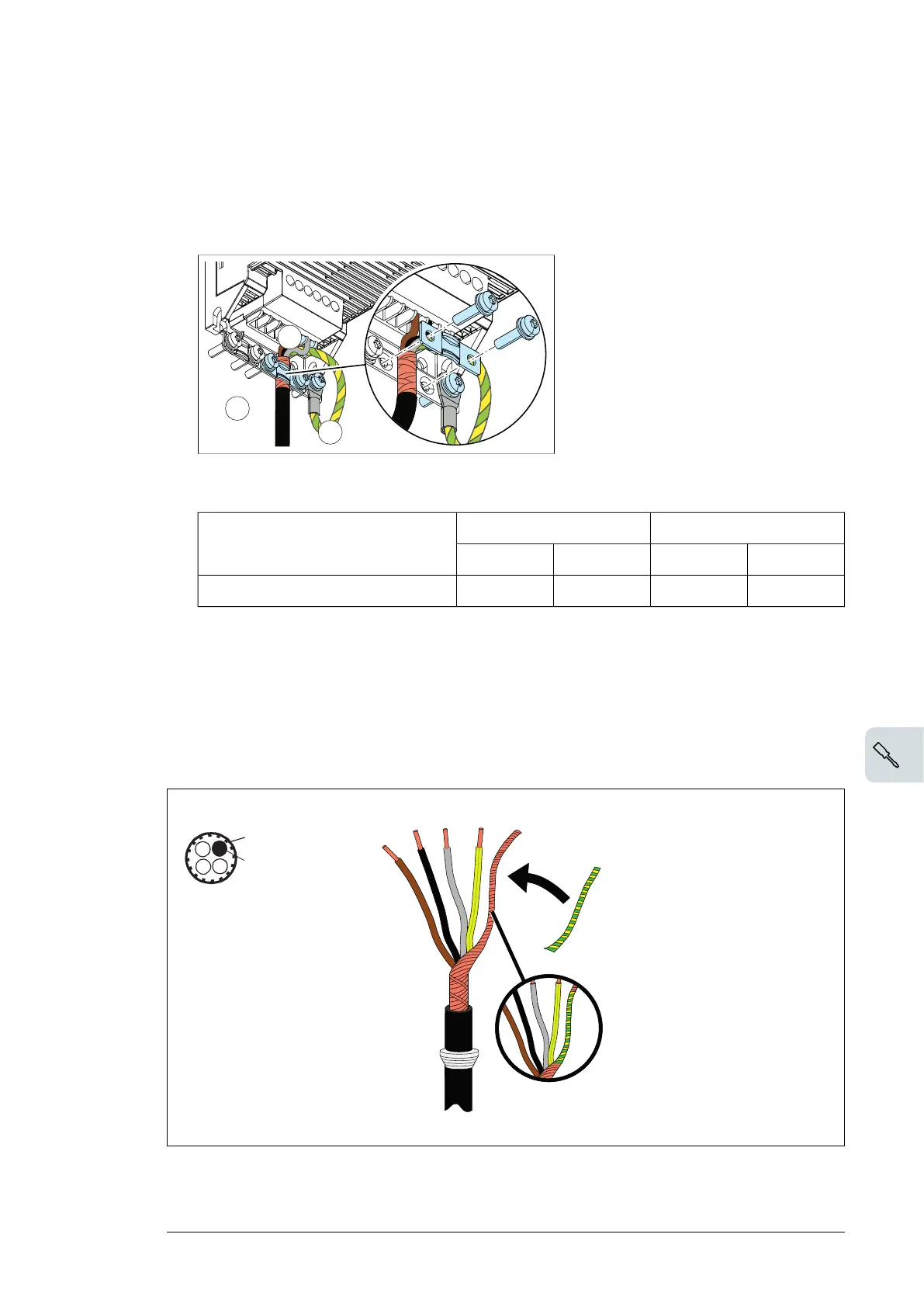

4. Prepare the ends of the cable as illustrated in the figure.

Note: The bare shield will be grounded 360 degrees. Mark the pigtail made from

the shield as a PE conductor with yellow-and-green color.

Frame size R0…R1 R2

N·m lbf·ft N·m lbf·ft

T1/U. T2/V. T3/W 0.5…0.6 0.4 1.2…1.5 0.9…1.1

3b

3c

3a

PE

PE

• Tighten the screws to the torque given below.

R2R0…R1Frame size

lbf·ftN·mlbf·ftN·m

0.9…1.11.2…1.50.40.5…0.6T1/U. T2/V. T3/W

Input power cable

4. Prepare the ends of the cable as illustrated in the figure.

Note:

The bare shield will be grounded 360 degrees. Mark the pigtail made from the shield as a

PE conductor with yellow-and-green color

5. Connect the input power cable as follows:

• Connect the twisted shield of the cable to the grounding terminal (5a).

Electrical installation 73

Loading...

Loading...