4. Setting the Laser Light Output Schedule

101

ML-5120A

Chapter 2 Various Settings

Introduction Part

Installation and

Preparation Part

Operating Part Maintenance Part Appendixes

Setting the Output Schedules for Seam Processing

The method of setting the output waveform for seam processing by using the

fade-in/out function after displaying the SEAM screen is explained below.

⇒

Only in the FIX or FLEX mode, the waveform for seam processing can be set.

1

Setting the Output Schedules

Taking seam processing in which laser light is continuously output 100 times, as an

example, the output count of "POINT 01" to "POINT 06" and energy are set. The en-

ergy at the beginning/end of laser light output is made weaker by the fade function.

This prevents an overlapped portion at circumferential seam processing against an

excessive burn and makes the processing mark of the nal shot inconspicuous.

⇒

The fade function can also be set for other processes than the beginning/end of

processing.

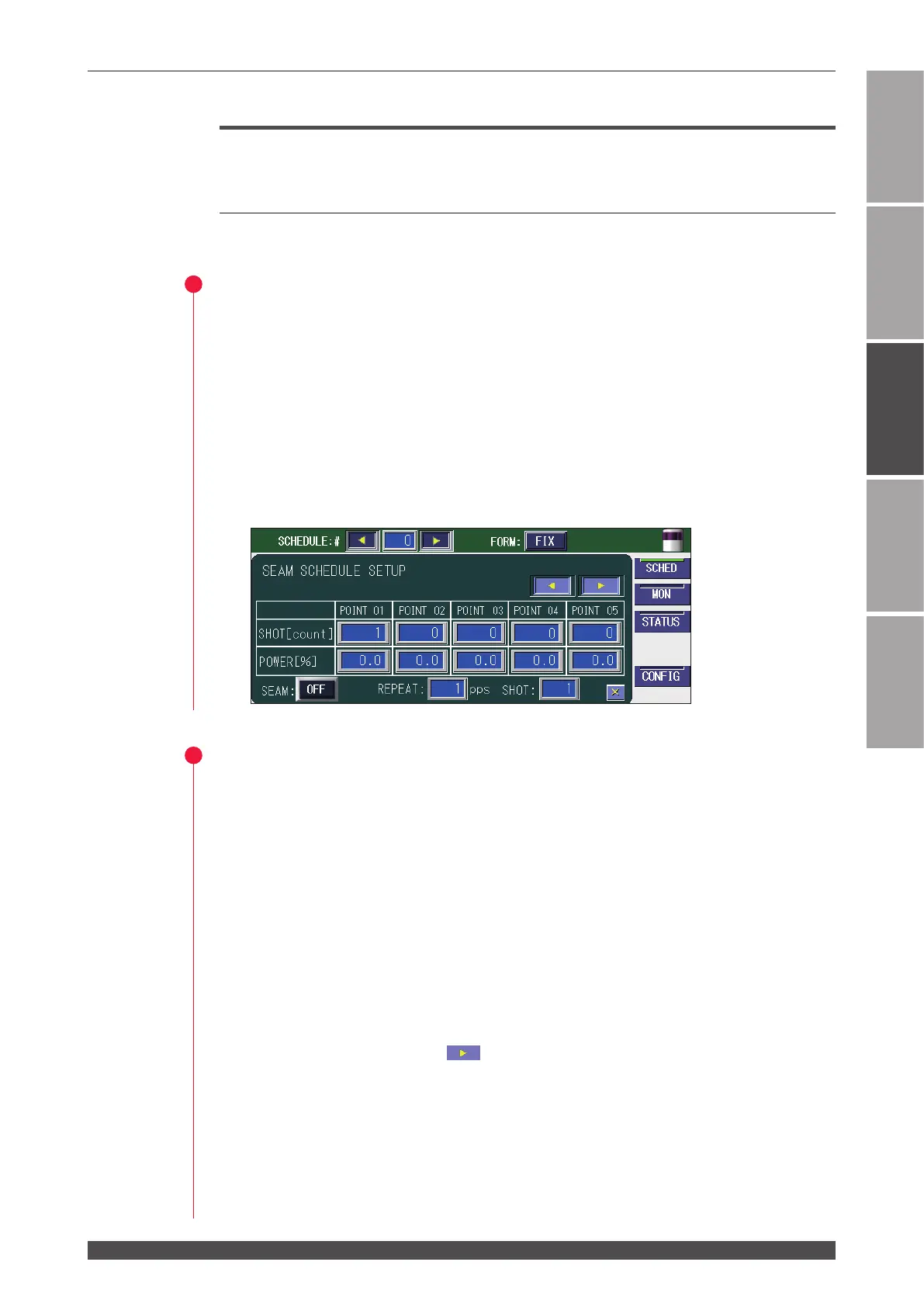

(1) Press the "SEAM" button to display the SEAM screen.

2

Setting the Fade-in/out Function

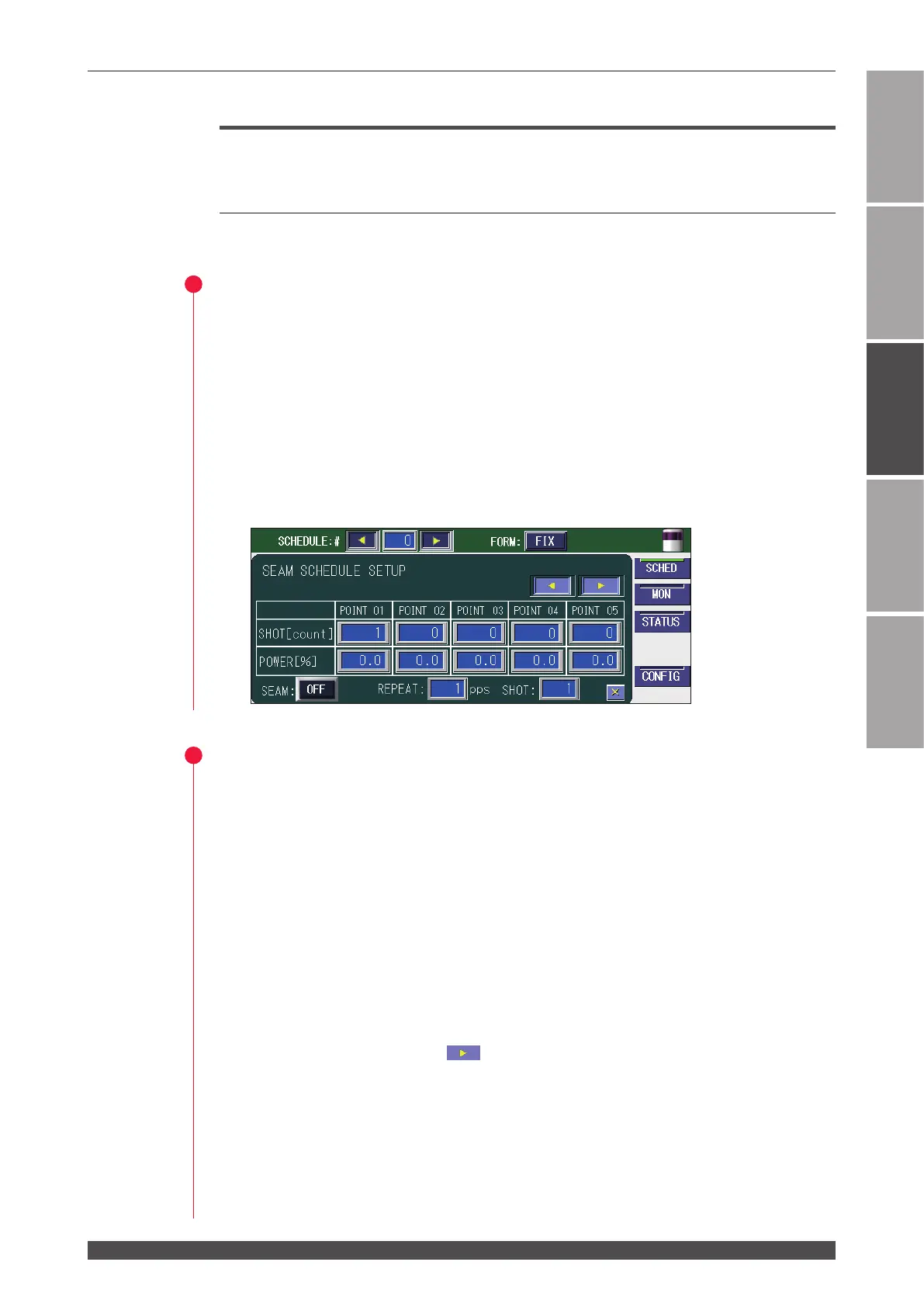

(1) Press the "SHOT [count]" setting button of "POINT 01."

Enter the laser light output count by using the numeric keypad and then press the

ENT key. Set 0001 because of the rst output count.

⇒

For "SHOT [count]" of "POINT 01", only 1 can be set.

(2) Press the "POWER [%]" setting button of "POINT 01."

Enter the laser output value (%) by using the numeric keypad and then press the

ENT key.

Set the ratio to "PEAK POWER" set on the SCHEDULE screen in the range of 0

to 150.0%.

(3) Likewise, set "SHOT [count]" and "POWER [%]" of "POINT 02" to "POINT 06."

⇒

For "POINT 06", press the button to scroll the POINT display column to the

right. Then, it is displayed.

Loading...

Loading...