Inspection intervals - maintenance notes

Instruction handbook b maXX BM3000, BM3200, BM3300

Document no. 5.11018.11 Baumüller Nürnberg GmbH

168

of 218

9.3

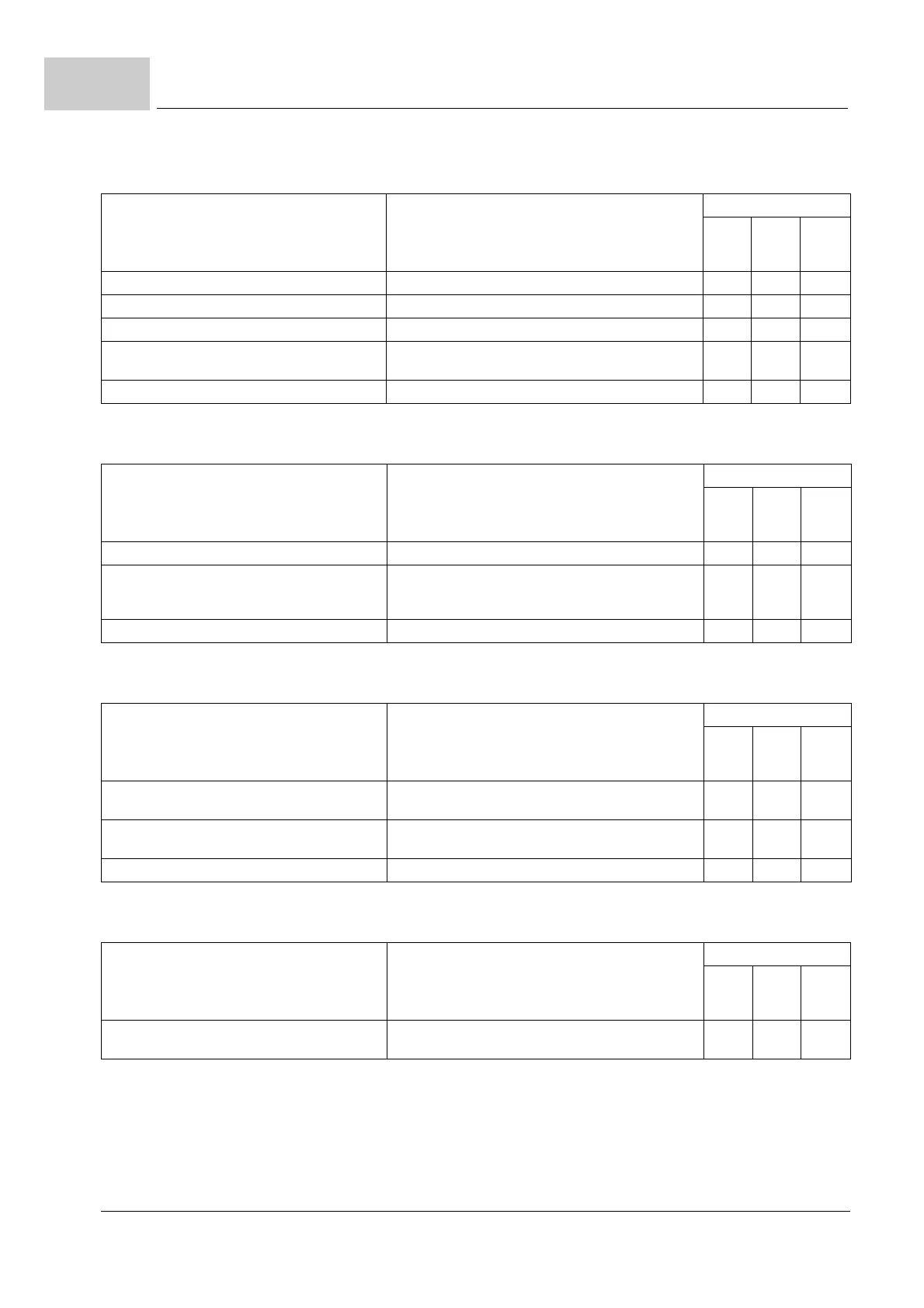

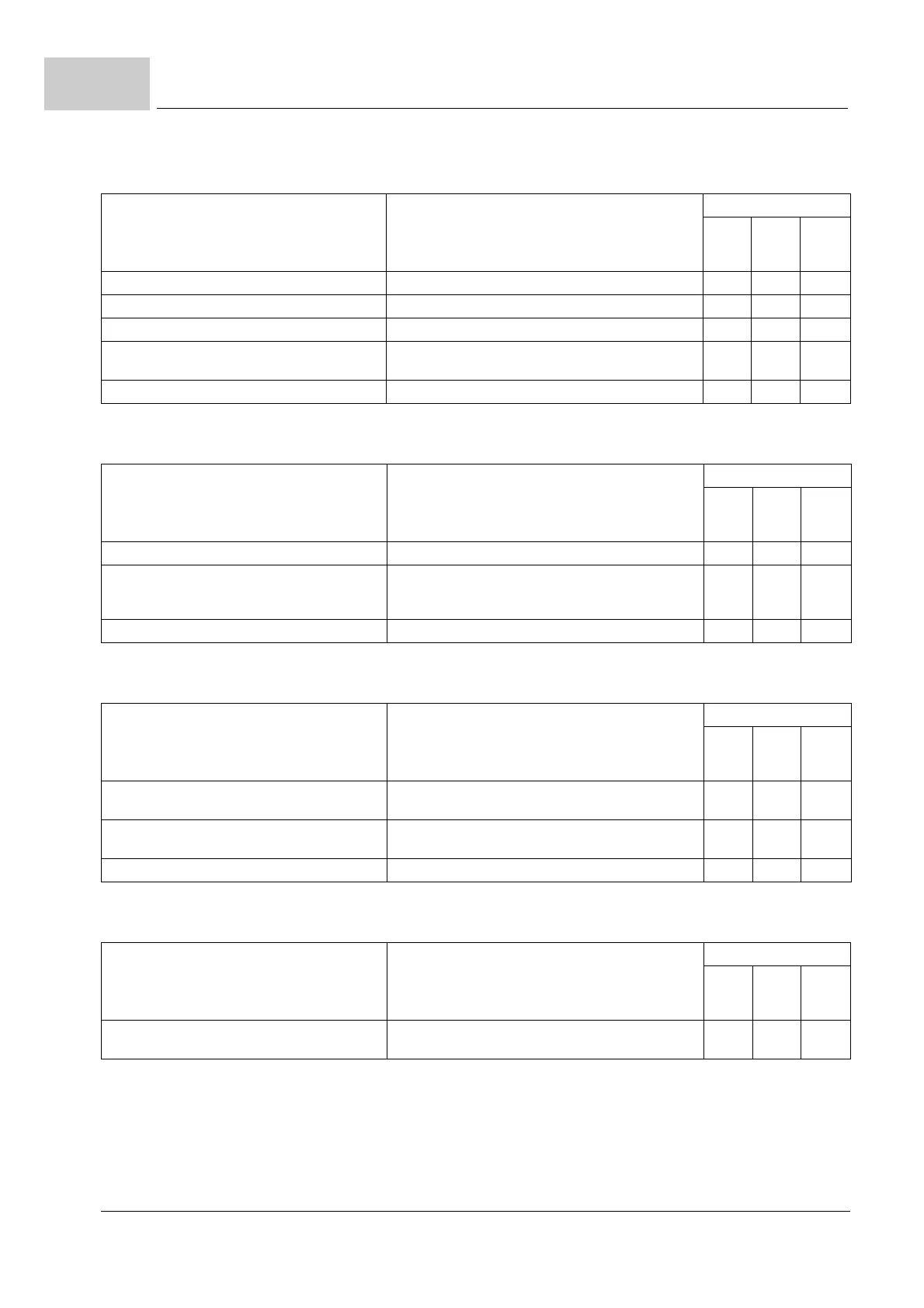

m Mechanical parts

Check points Methods and criteria Inspection intervals

Daily Semi-

annu-

ally

Annu-

ally

Are there any abnormal noises or vibrations? Visual and audio check O

Are there any loose screws? Tighten the screws. O

Are there any bent or damaged parts? Visual inspection O

Have there been any color changes due to over-

heating?

Visual inspection O

Are there any dust or dirt deposits? Visual inspection O

m Power supply

Check points Methods and criteria Inspection intervals

Daily Semi-

ann

u-

ally

Annu-

ally

Are there any missing or loose screws? Replace the screws or, respectively

, tighten them. O

Is there any deformation, cracking, damage or

color

change on the device as a result of overheat-

ing or aging?

Visual inspection O

Are there any dust or dirt deposits? Visual inspection O

m Connections and circuitry of the power supply

Check points Methods and criteria Inspection intervals

Daily Semi-

ann

u-

ally

Annu-

ally

Does the wiring indicate any color or shape

change

s due to overheating?

Visual inspection O

Is the wiring insulation damaged or is it discol-

ored?

Visual inspection O

Is there any damage? Visual inspection O

m Transformer and chokes in the main circuit

Check points Methods and criteria Inspection intervals

Daily Semi-

ann

u-

ally

Annu-

ally

Are there any abnormal vibrations or noticeable

o

dors?

Visual inspection, audio check and odor check O

Loading...

Loading...