54733-10BA2L

2 – 208 02.2017

2 Installation Volume 2

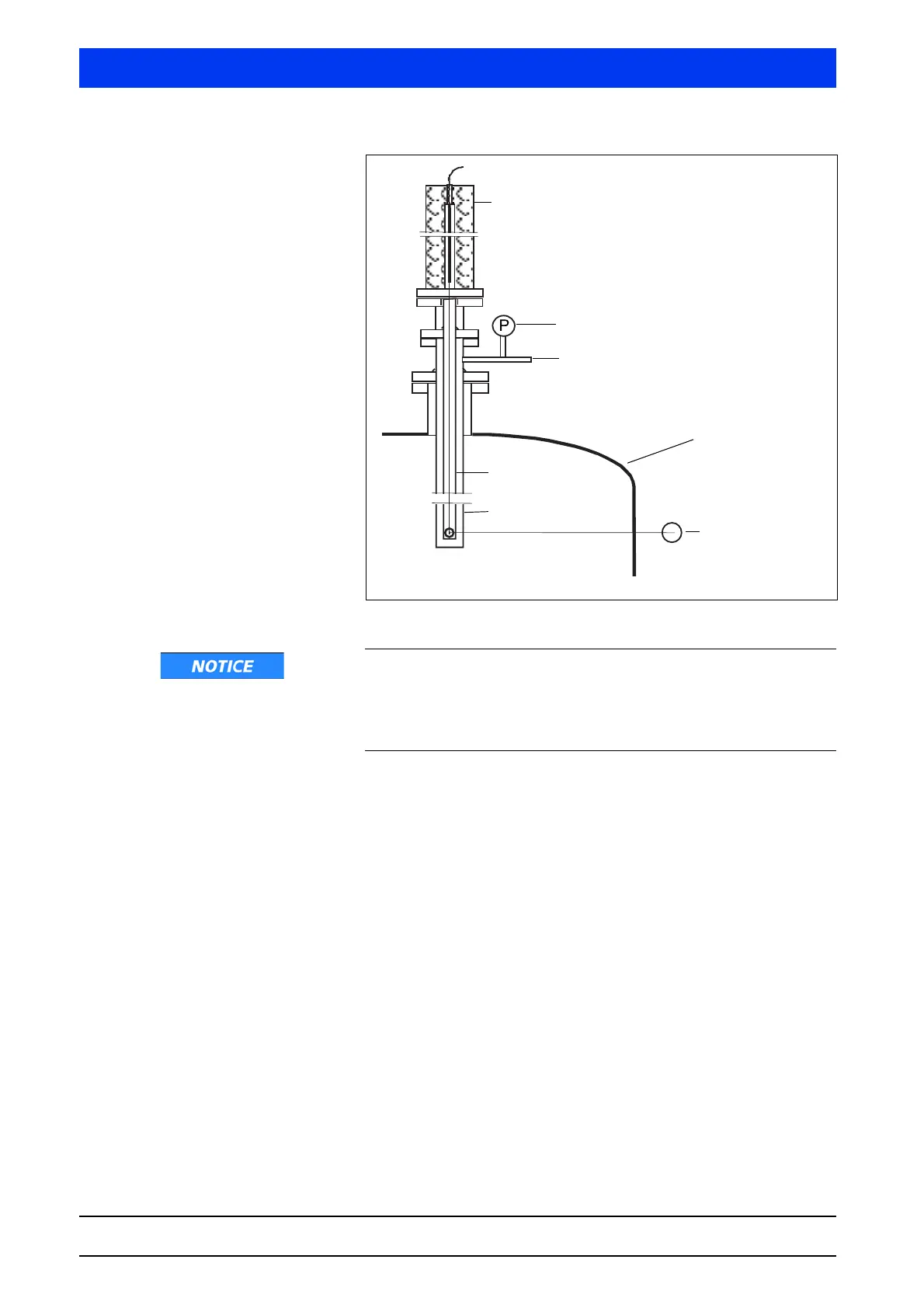

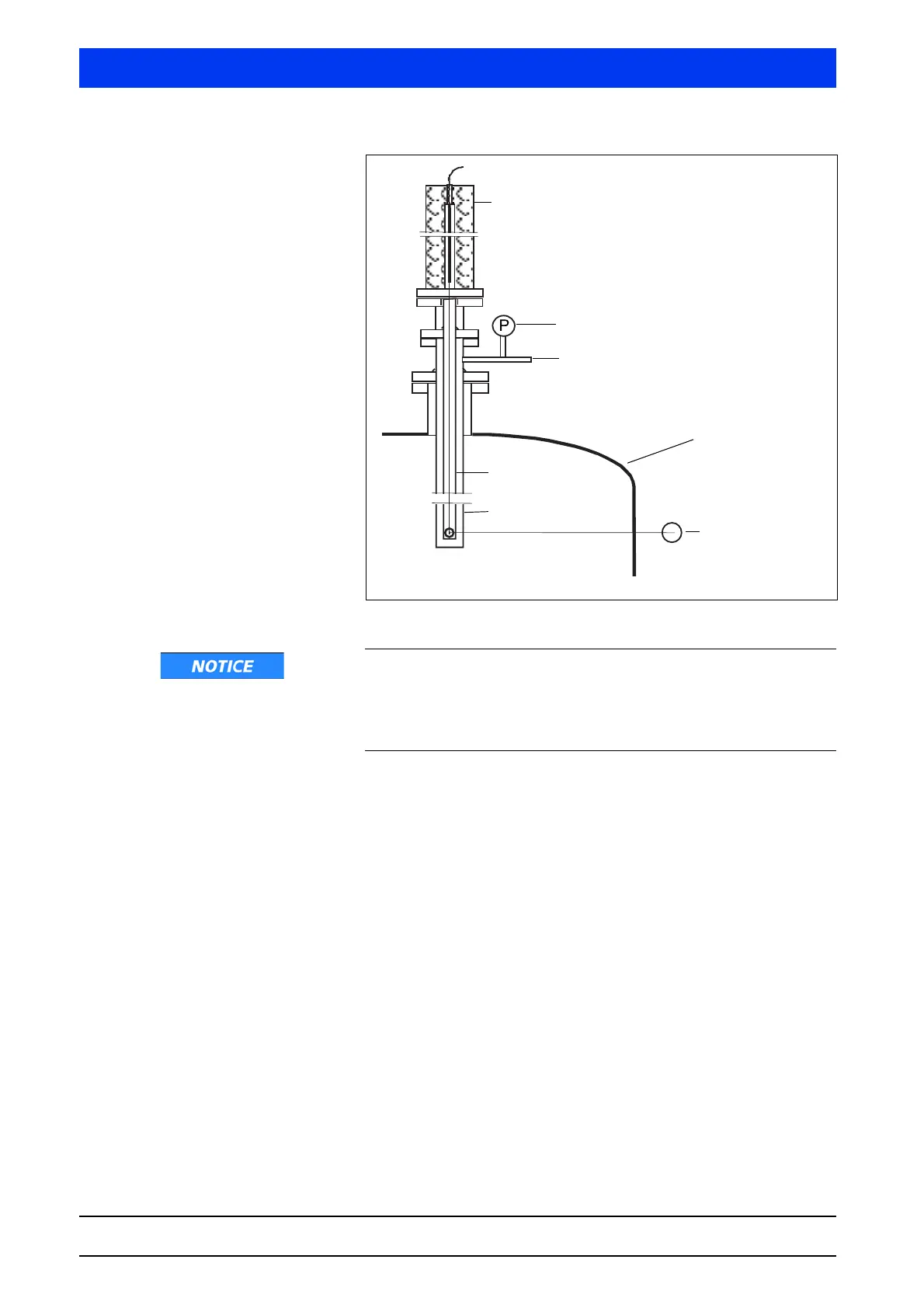

Fig. 2-31 Dip tube installation with point source and point detector

If the shieldings are employed in aggressive atmospheres, the steel

cable or the shaft core and the latch mechanism have to be

checked for corrosion in regular intervals. The intervals between

the checks have to be defined by the operator such that a malfunc-

tion of the mechanism due to corrosion is ruled out.

Version with shaft core

Instead of a steel cable, a shaft core is installed which consists of a

spring wire. This allows you to install flange shieldings to the vessel

from below or from the side and to insert the source from there into

the dip tube and to position it. The shaft core is inserted completely

into the shielding to position the source. The immersion depth of

the source is then fixed by a clamping screw, not with the position-

ing screw. In exceptional cases, it may be necessary, with point

sources, to determine the position accurate to the millimeter to

make sure that the beam path does not hit any vessel installation.

Shielding with

source

Pressure control

Protection gas

Vessel wall

Detector

Dip tube

Protection tube

Loading...

Loading...