SENSseries LB 480 Level measurement

BERTHOLD TECHNOLOGIES GmbH & Co. KG

3 – 345

Volume 3 Menu Structure

3

•MANUAL GDA (Gas Density Adjustment)

If the container in operation is under gas pressure (> about 2

bar) and the calibration cannot be carried out under operating

pressure, then it is possible to calculate in advance the count

rates that should be obtained under operating pressure. Addi-

tional parameters are displayed which are required for the com-

pensation.

– Gas measuring path

– Setup Gas Density

– Gas Density at Op

Please note that with a multi-point calibration the GDA can only

be used when the same gas density is available at all calibration

points during calibration. Only the calibration point at 100% is

excluded, provided that the measurement path in the container

is completely filled with product.

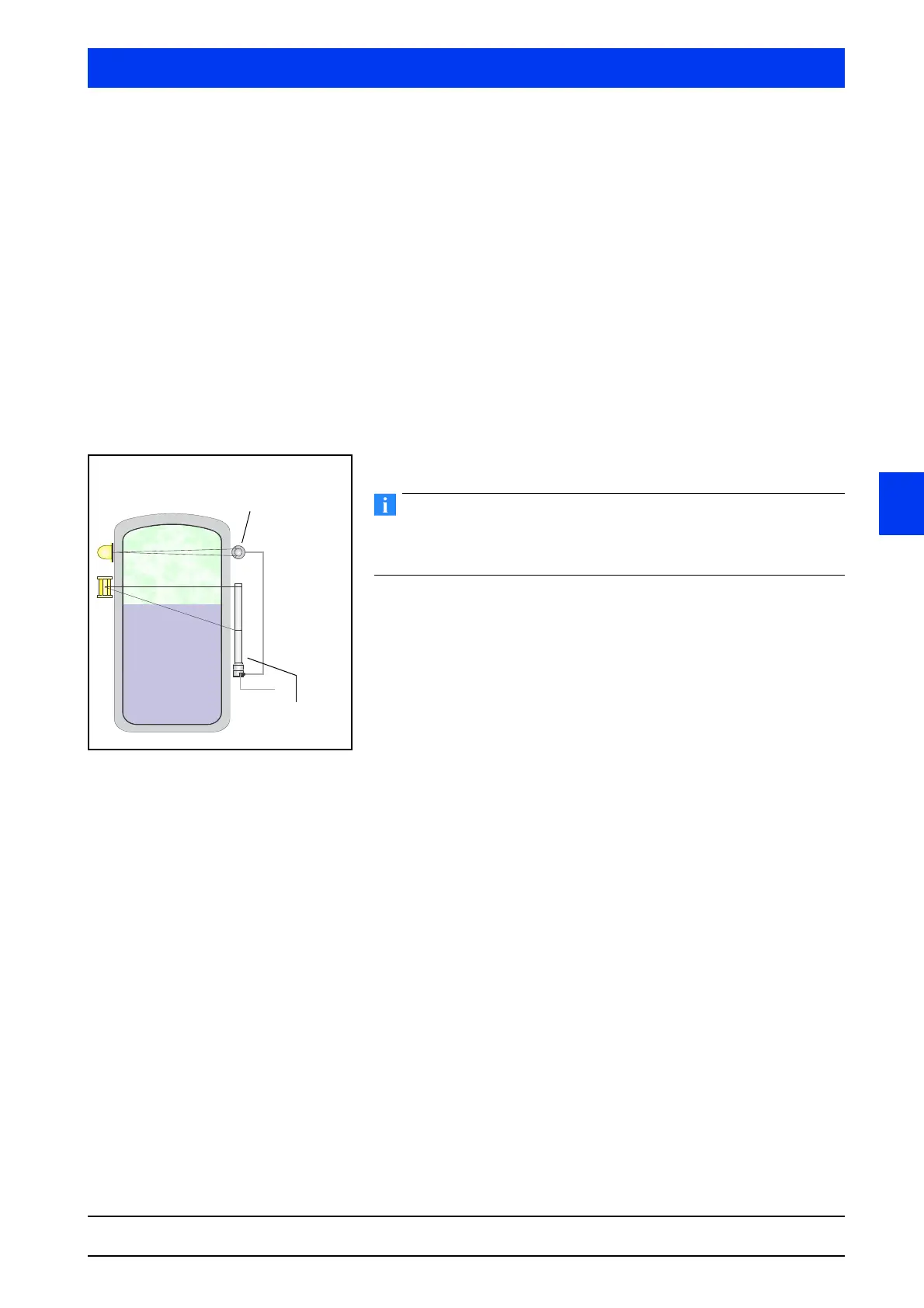

•AUTO GPC (Gas Property Compensation)

This function requires special knowledge and should be enabled

only by a Berthold service engineer, or by a specially trained per-

son.

If the vessel is in operation under gas pressure (> about 2 bar)

and the gas pressure is not constant, then a continuous gas

density compensation is advisable. An additional measurement

is required which is arranged above the liquid level measure-

ment and constantly measures the gas density in the container.

Additional parameters required for this calibration appear on

the Calibration menu.

A further prerequisite for GPC is that the source used for level

measurement as well as for compensation measurement con-

tain the same isotope. This means, if a level measurement is

carried out using Cs-137, then the compensation measurement

must also be carried out with Cs-137.

GPC cannot be used for a level measurement with point source

and point detector.

Detector for GPC

compensation

measurement

RS 485

Detector for level

measurement

Loading...

Loading...