TECHNICAL

SPECIFICATIONS

2

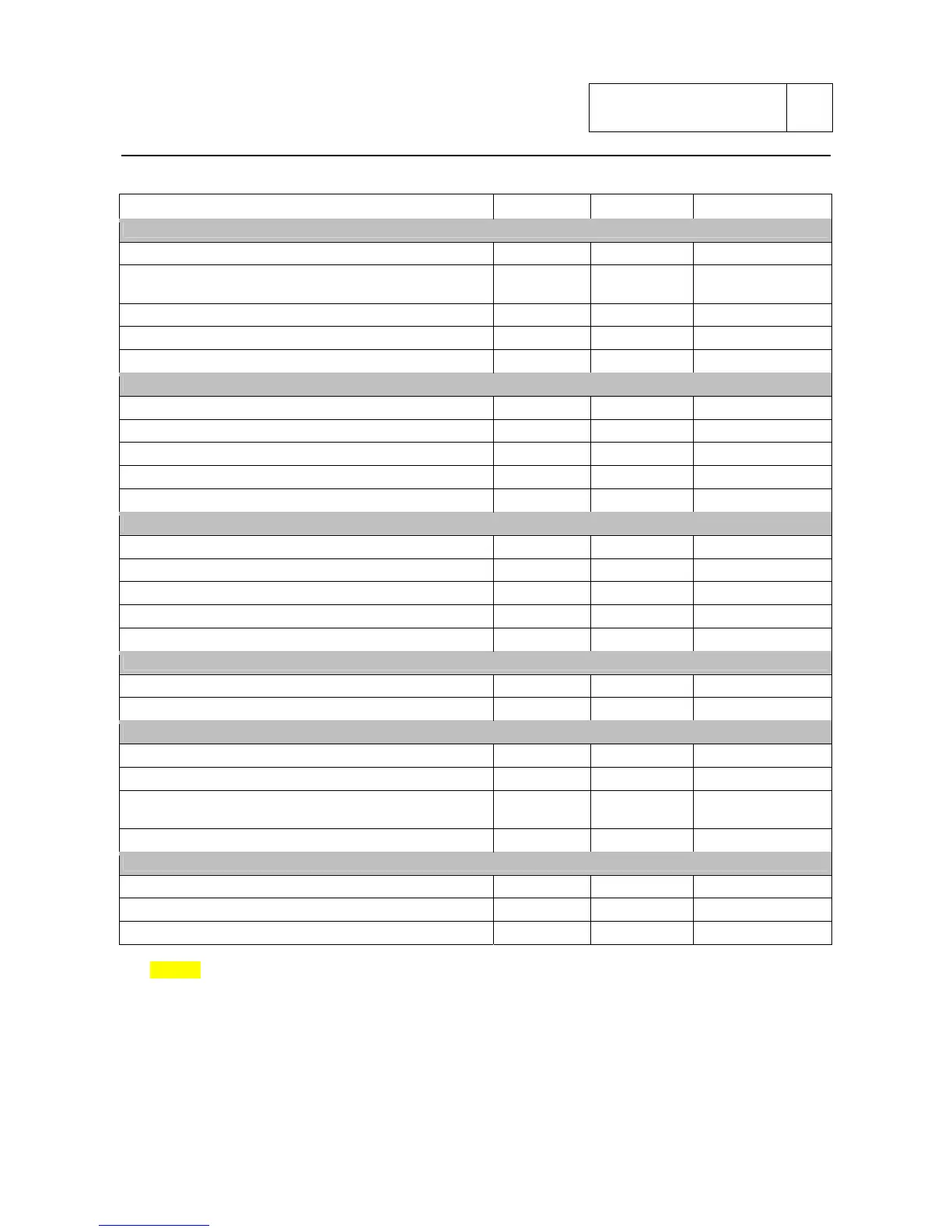

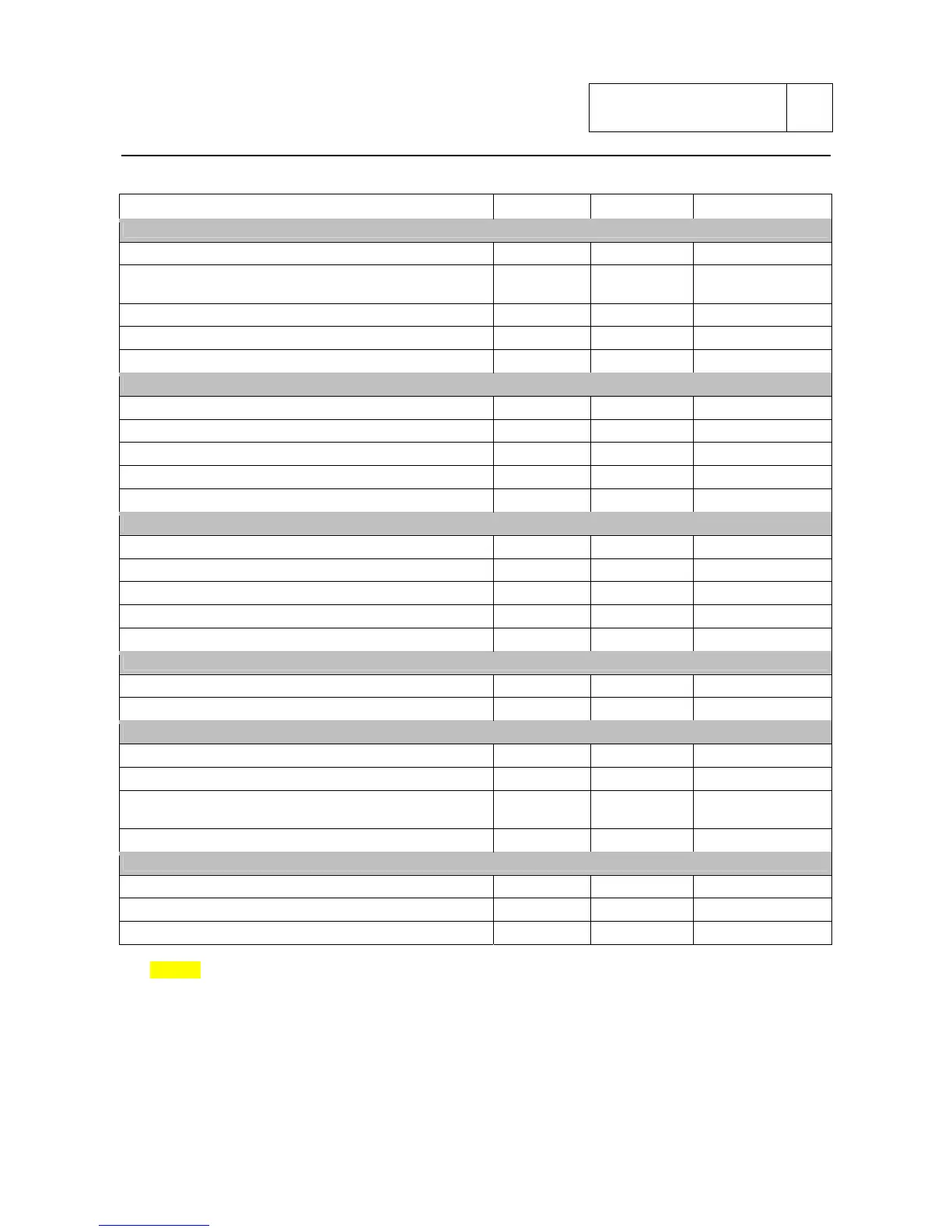

Description Size (mm) Torque (Nm) Notes

SWING ARM

Eccentric clamp fixing screw M8x22 25 Loctite 243

Swing arm plates fixing screw M10x1,25 50

Loctite 243

(grease under head)

Fixing screw of the upper and lower chain slider M4x8 3 Loctite 243

Fixing screw of the side chain slider M4x12 3 Loctite 243

Swing arm pivot fixing screw M16x1,5x20 55 grease under head

FRONT BRAKE SYSTEM

Brake calliper fixing screw M10x1,25x65 45 Grease

Brake bleeding screw M10x1 20/man

Junction screw of brake hoses to calliper and master cylinder M10x1 20

Fixing screw of the master cylinder to handlebar M6x1,25 11

Fixing screw of the brake oil tank to master cylinder M6x10 10 Loctite 243

REAR BRAKE SYSTEM

Fixing screw of the rear brake calliper M8x20 25 Grease

Fixing screw of the rear master cylinder M6x16 10 Loctite 243

Fixing screw of the rear brake oil tank M5x30 5 Loctite 243

Bleeding screw M10x1 20/man

Junction screw of brake hoses to calliper and master cylinder M10x1 20

FRONT WHEEL

Fixing screw of the front wheel pivot M20x1x13 ???? Grease

Fixing screw of the front brake disc to rim M8x18 22 Loctite 243

REAR WHEEL

Fixing screw of the front brake disc to rim M8x20 22 Loctite 243

Fixing screw of the shock absorber flange to rim M8x25 22 Loctite 243

Shock absorber small pivot + rear sprocket fixing nut to

sprocket holder flange

M10x1,25 40

Loctite 243

(grease under head)

Rear wheel pivot M26x2 100 Grease

HANDLEBAR – CLUTCH CONTROL – THROTTLE CONTROL

Fixing screw of semi-handlebar to fork clamp and fork stem M8x30 25 Grease

Rotation screw semi-handlebar to clamp M4x8 3 Loctite 243

Fixing screw of the clutch pump clamp to semi-handlebar M6x25 11

NOTES

The tightening torque must be applied slowly and gradually using a calibrated torque wrench tool.

In case of screwing with automatic impact wrench, the reference torque must be reduced of 10%.

Sub 2-14

Loading...

Loading...