TECHNICAL

SPECIFICATIONS

2

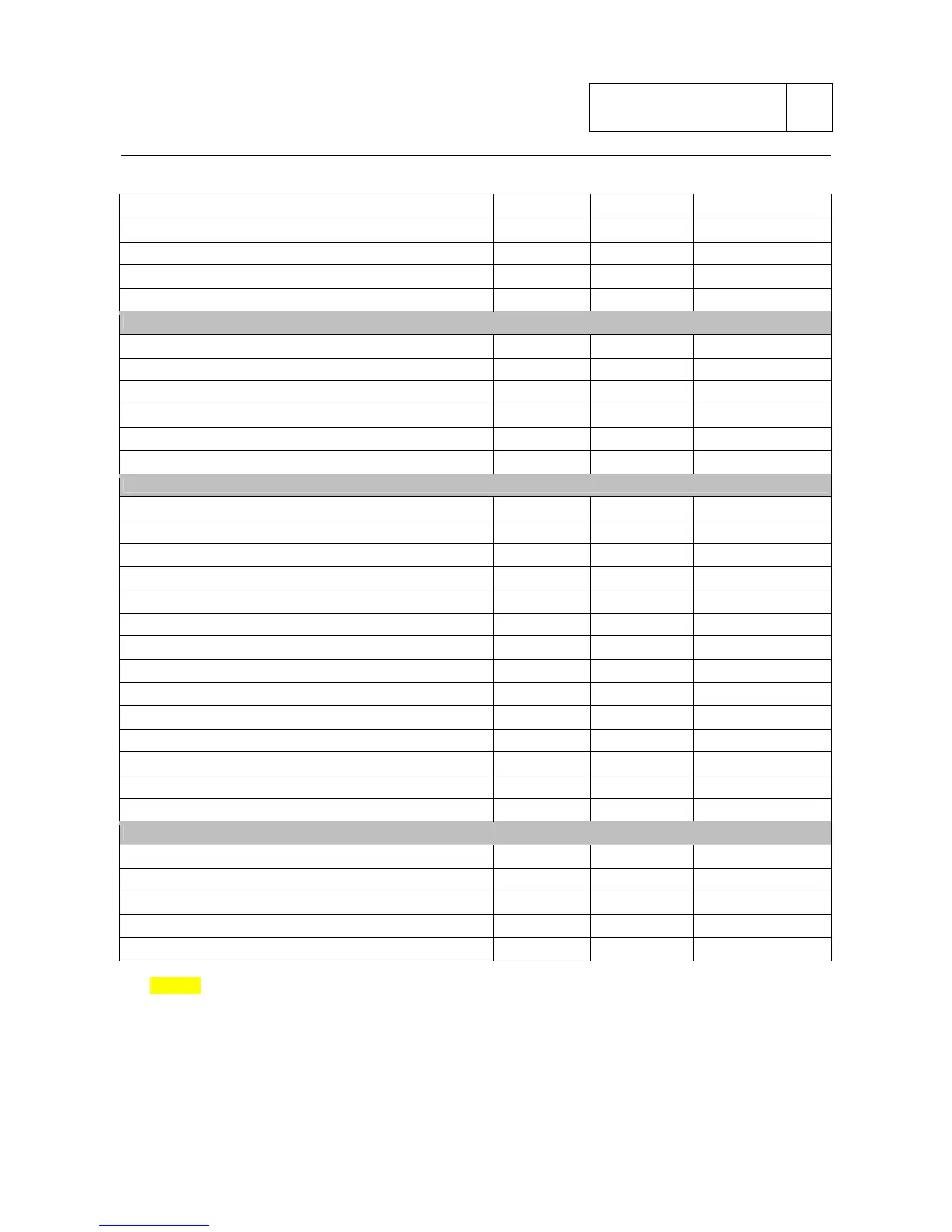

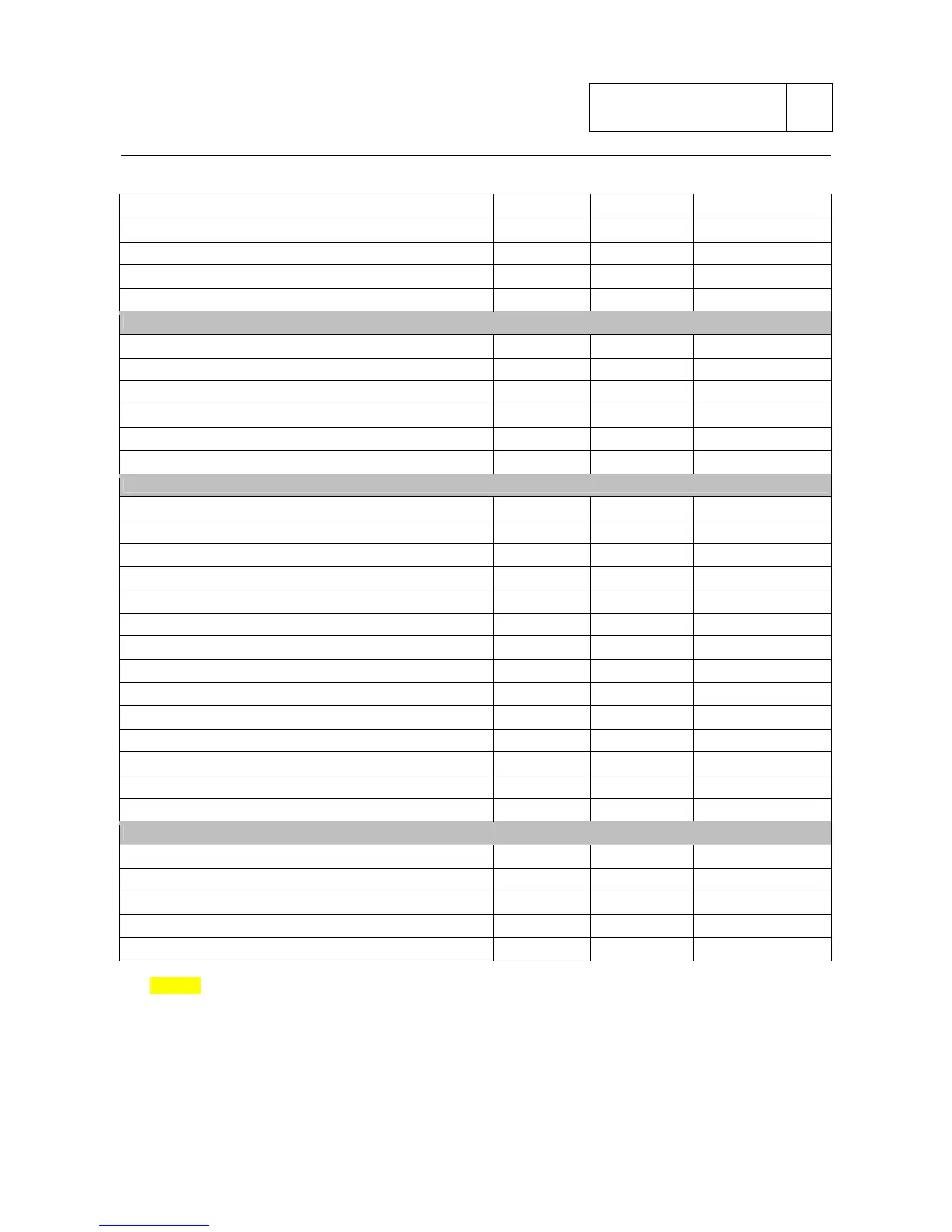

Description Size (mm) Torque (Nm) Notes

Fixing screw of the master cylinder clamp to semi-handlebar M&x1x25 11

Throttle control covers fixing screw M6x1x20 10

Fixing screw of the oil tank plate holder to clutch pump M6x10 10 Loctite 243

Clutch small piston fixing screw M6x16 10

FRAME

Fixing screw of aluminium plates to frame M10x1,25 50

Engine/frame pivot fixing nut M12x1,25 55 Grease

Fixing screw of the load-bearing tail to frame plates M8x20/25 22

Screw + fixing nut of main switch to frame M8 20 Loctite 243

Fixing screw of upper fairing small frame to the frame M6x16 11 Loctite 243

Fixing screw of upper fairing small frame to the main switch M5x10 5

FOOTPEGS AND LEVERS

Fixing screw of foot peg to frame M8x16 22 Loctite 243

Fixing screw of the foot protection to the foot peg M4x8 3 Loctite 243

Fixing screw of the foot peg to the left holder M8x20 22 Loctite 243

Lock nut of gear counter bar M5 6

Fixing screw of the gear counter lever clamp M6x20 10 Loctite 222

Screw + fixing nut of gear control bar uniball M5 5

Fixing screw of gear lever to foot peg holder M8x1,25 22 Loctite 243

Gear lever clamp fixing screw M5x14 5 Loctite 222

Fixing screw of the foot peg to the right holder M8x22 22 Loctite 243

Fixing screw of rear brake lever to small plate M10x1,25 50 Loctite 243

Fixing screw of brake lever small plate to engine M10x1,25 50 Loctite 243

Brake lever clamp fixing screw M5x14 5 Loctite 222

Screw+ fixing screw of master cylinder rod uniball M6x30 10

Master cylinder bar lock nut M6 10

LIQUID COOLING

Fixing screw of the radiator to the frame M6x22 10

Water drain plug on pump cover M10x1 18

Screw+ fixing nut of radiator to support stirrup M6x25 10

Radiator bulkhead fixing screw M6x10 10

Coolant expansion tank fixing screw M5x10 5

NOTES

The tightening torque must be applied slowly and gradually using a calibrated torque wrench tool.

In case of screwing with automatic impact wrench, the reference torque must be reduced of 10%.

Sub 2-15

Loading...

Loading...