Appendix B: Wiring B-3

HOME

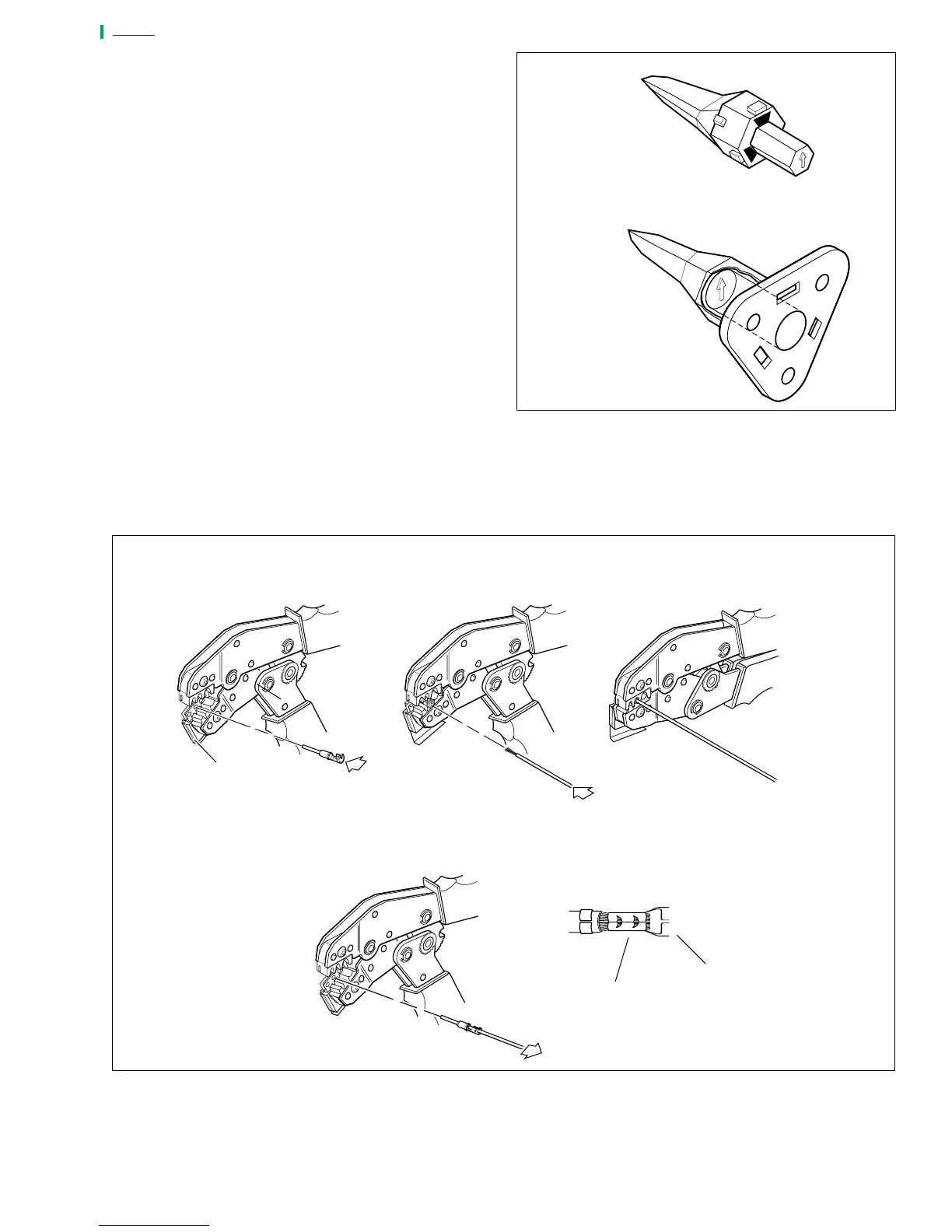

2. Raise locking bar by pushing up on bottom flange. With

the crimp tails facing upward and the rounded side of the

contact barrel resting on the concave split level area of

the crimp tool, insert contact (socket/pin) through middle

hole of locking bar.

3. Release locking bar to lock position of contact. If the

crimp tails are slightly out of vertical alignment, the crimp

tool automatically rotates the contact so that the tails

face straight upward. When correctly positioned, the

locking bar fits snugly in the space between the contact

band and the core crimp tails.

4. Strip lead removing 0.1562 in. (4.0 mm) of insulation.

Insert wires between crimp tails until ends make contact

with locking bar. Verify that wire is positioned so that

short pair of crimp tails squeeze bare wire strands, while

long pair folds over insulation material.

5. Squeeze handle of crimp tool until tightly closed. Tool

automatically opens when the crimping sequence is

complete. Raise up locking bar and remove contact.

NOTE

Inspect the quality of the core and insulation crimps. Distor-

tion should be minimal.

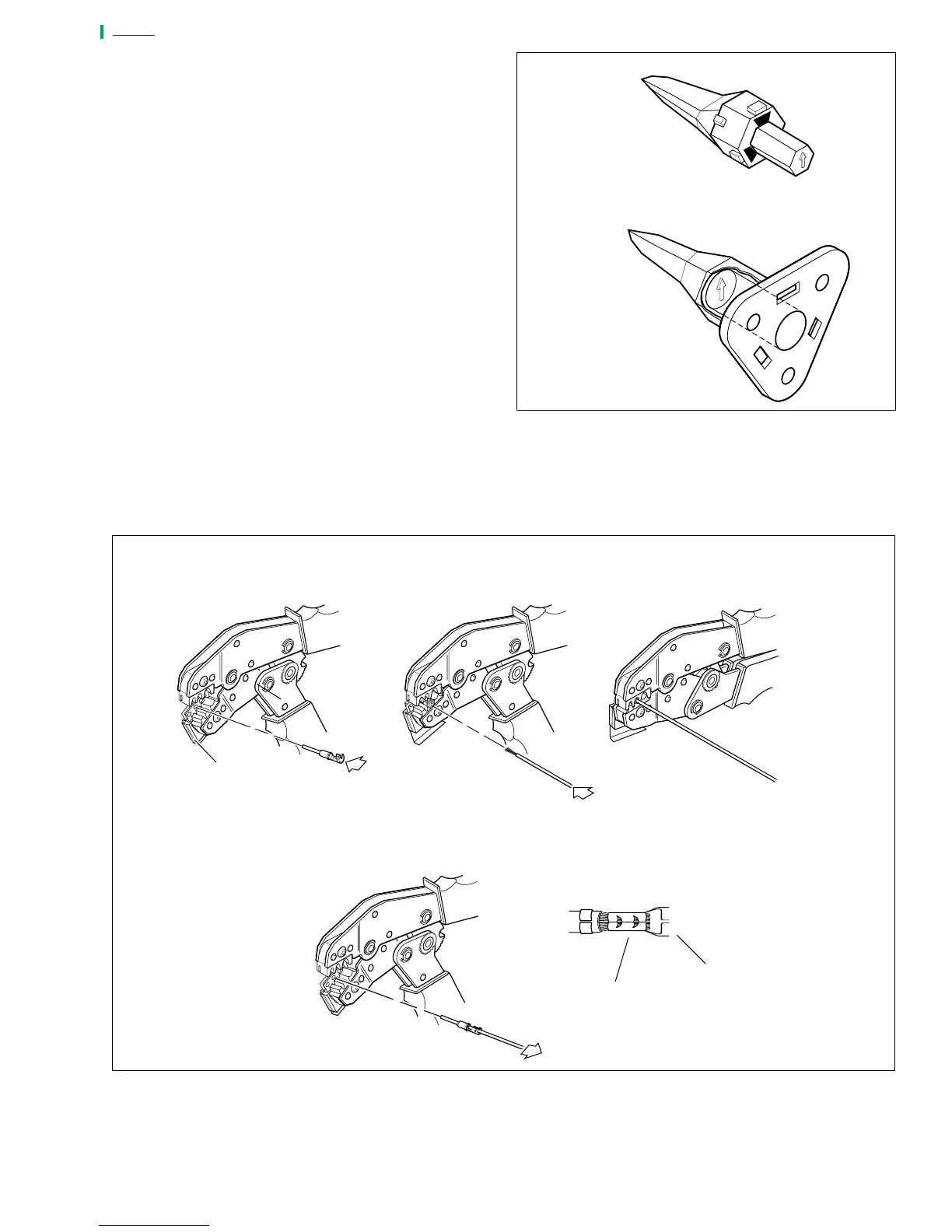

Figure B-2. 3-pin Locking Wedge Orientation

a0267x7x

Socket

Housing

Pin

Housing

Arrow Points to

External Latch

Figure B-3. Deutsch Crimping Procedure

1. Insert contact through middle

hole of locking bar.

2. Insert stripped lead until it

contacts locking bar.

3. Close and squeeze crimp tool.

4. Raise locking bar and

remove contact.

5. Inspect quality of core and

insulation crimps.

a0268x7x

Locking bar

Insulation crimp

Core crimp

Loading...

Loading...