2002 Buell P3: Drive/Transmission 6-41

HOME

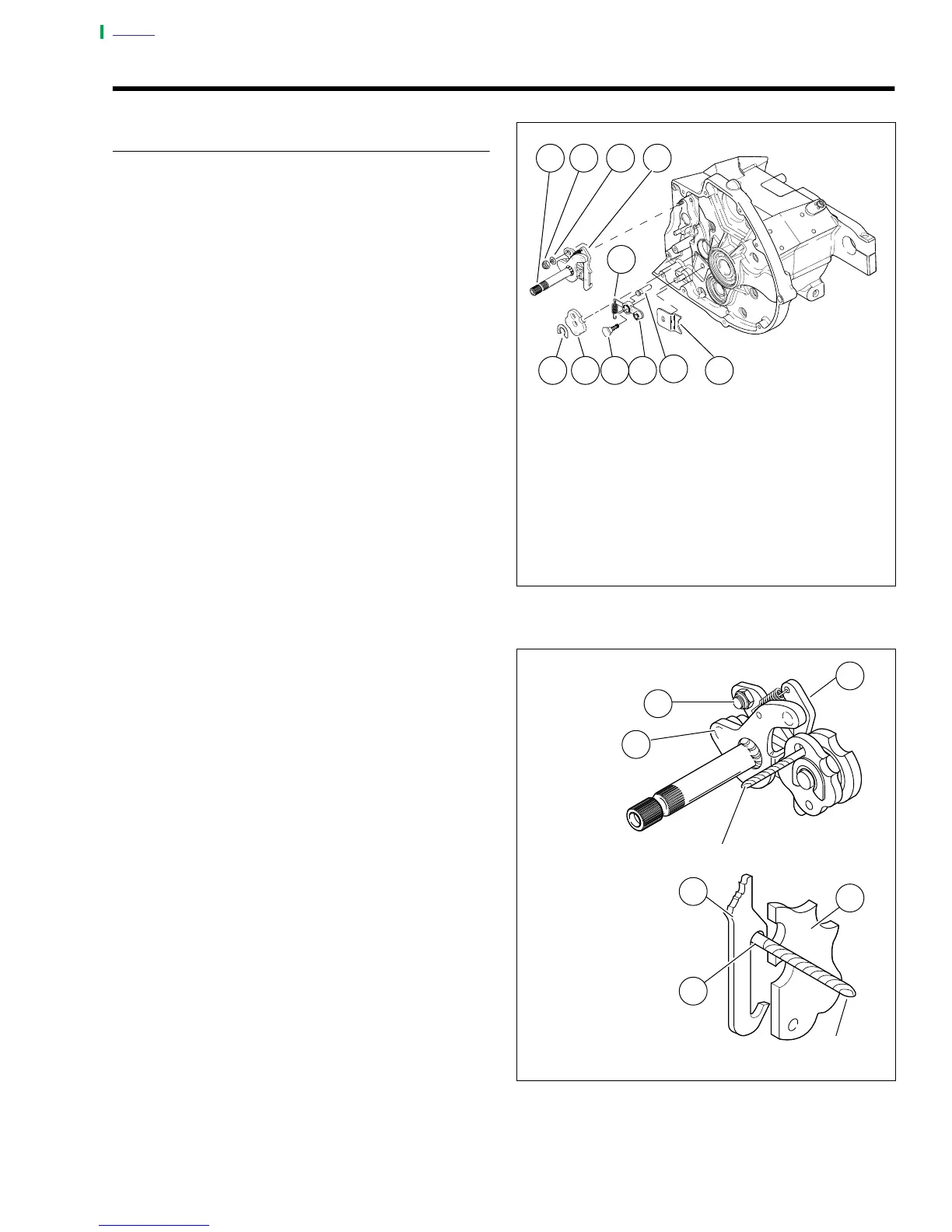

SHIFTER PAWL ADJUSTMENT 6.15

ADJUSTMENT

1. See Figure 6-60. Lift pawl over drum pins and place

shifter shaft assembly on studs at transmission case.

Loosely install a washer and locknut on each stud.

2. Install detent plate.

a. Place detent plate over drum pins.

b. Rotate plate until blind holes in plate align with pins

in end of shifter fork drum.

c. Install new retaining ring using SHIFT DRUM

RETAINING RING INSTALLER (Part No. HD-

39151).

3. Verify that retaining ring is fully engaged with drum

groove.

4. Attach loop of spring over and into groove in post.

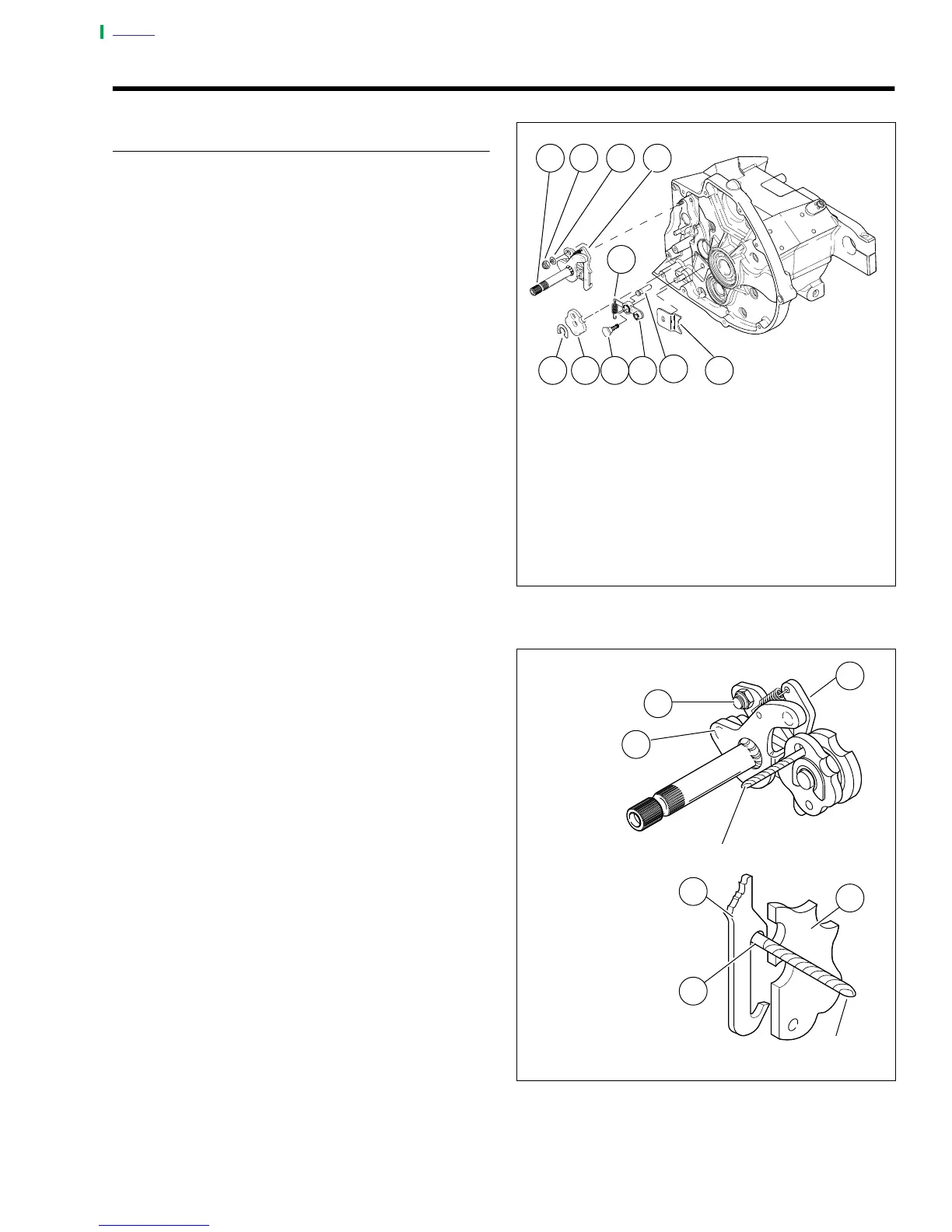

5. See Figure 6-61. Align shifter shaft.

a. Place transmission in third gear.

b. Place a No. 32 drill bit (0.116 in. dia.) through hole in

detent plate (3), and between pawl (2) and drive pin

at end of shifter drum shaft.

c. Push down top of crank (4) to remove all clearance

between pawl and drill bit; this will correctly align

pawl to shift drum pins (do not push down with too

great a force, as this might cause the shifter drum to

rotate).

d. With bit in place, tighten shifter shaft assembly bot-

tom locknut (1) first to 90-110 in-lbs (10-12 Nm).

Then, tighten shifter shaft assembly top locknut (1)

to the same torque.

e. Remove drill bit.

6. See Figure 6-52. Place new quad ring over threaded end

of fifth gear, and position next to the gear taper. Install

spacer over threaded end of fifth gear with chamfered

end toward quad ring. Slide spacer up against bearing.

7. Install seal.

a. Coat lips of seal with SPORT-TRANS FLUID.

b. Position seal over spacer with lips of seal toward

case.

c. Use MAIN DRIVE GEAR SEAL INSTALLER (Part

No. HD-41496) to gently tap seal into bore of case

until the outside of seal is flush with outer edge of

bore.

NOTE

It is acceptable to recess seal to about 0.030 in. (0.762 mm)

below outer edge of bore. Seal will be controlled by tool.

8. See Figure 6-62. Position retention collar next to end of

counter shaft with beveled side facing outward.

a. Apply several drops of LOCTITE

®

thread locker 243

(blue) to last few threads.

b. Insert screw (1) through retention collar (2) and

thread into end of shaft.

c. Place transmission in gear, and tighten TORX screw

(1) to 13-17 ft-lbs (18-23 Nm) torque.

Figure 6-60. Installing Shifter

Figure 6-61. Shifter Shaft Assembly Alignment

1. Shifter Shaft Assembly

2. Locknut (2)

3. Washer (2)

4. Shifter Pawl

5. Plate

6. Pin

7. Detent Arm

8. Detent Screw

9. Detent Plate

10. Retaining Ring

11. Spring

a0119x6x

4321

5

6

78910

11

a0164x6x

No. 32 drill bit (0.116 in. dia.)

Drill bit

1. Locknut (2)

2. Pawl

3. Detent Plate

4. Crank

5. Shifter Drum Pin

5

3

2

2

4

1

Loading...

Loading...