2002 Buell P3: Drive/Transmission 6-43

HOME

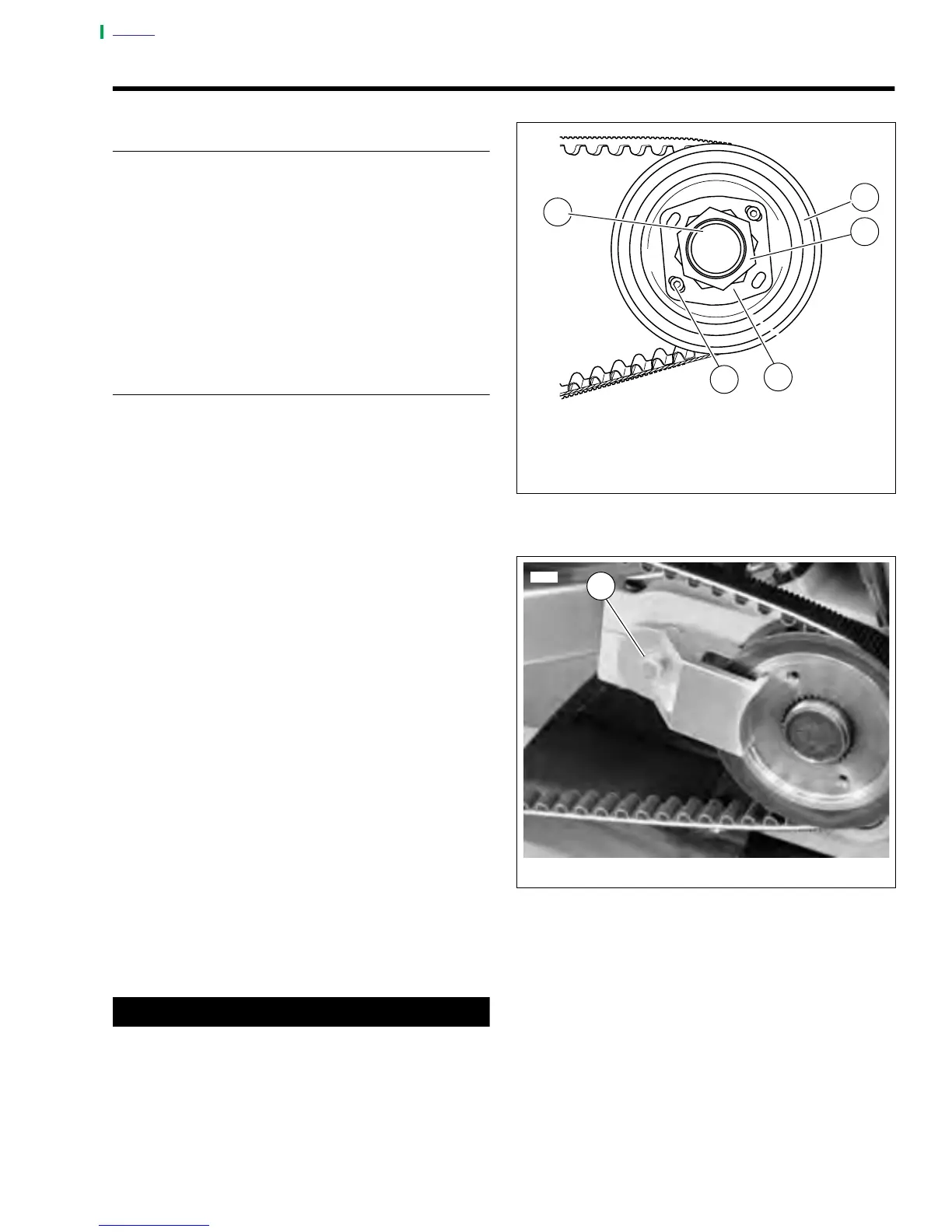

TRANSMISSION SPROCKET 6.16

REMOVAL

1. See Figure 6-63. Place transmission in first gear.

Remove two socket head screws (5) and lockplate (4).

NOTE:

Transmission sprocket nut has left-hand threads. Turn nut

clockwise to loosen and remove from main drive gear shaft.

2. See Figure 6-63. Remove transmission sprocket nut (3)

from main drive gear shaft (1).

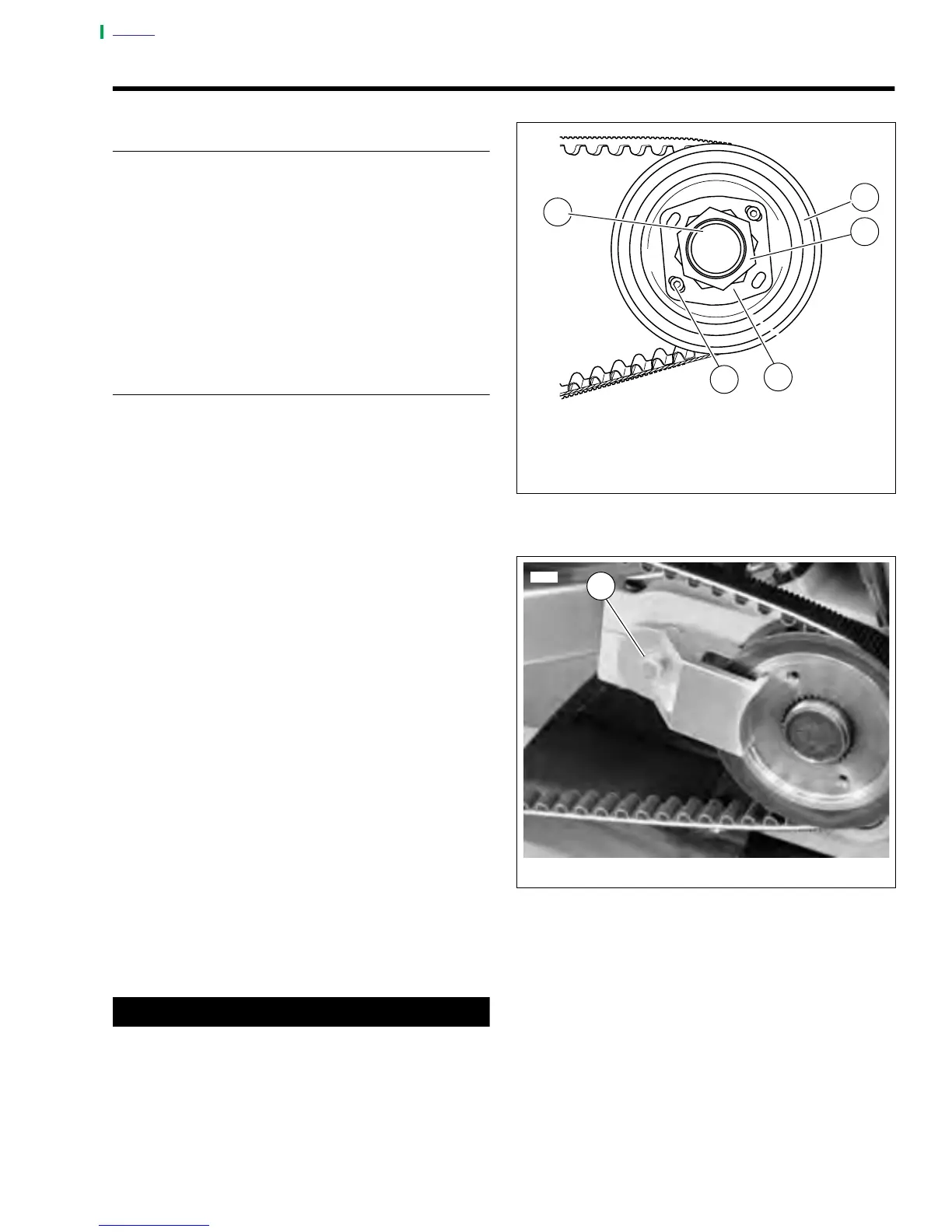

a. See Figure 6-64. Secure pulley using SPROCKET

LOCKING TOOL (1) (Part No. B-43982).

INSTALLATION

1. See Figure 6-63. Install transmission sprocket (2) with

secondary drive belt onto main drive gear shaft (1).

2. Place transmission in neutral.

3. Apply a few drops of LOCTITE

®

thread locker 262 (red)

to the left-hand threads of transmission sprocket nut

(3). Position nut with washer-faced side facing transmis-

sion sprocket. Turn the nut counterclockwise to install it

onto main drive gear shaft.

a. See Figure 6-64. Install SPROCKET HOLDING

TOOL (1) (Part No. B-43982) as shown.

b. See Figure 6-65. Use MAINSHAFT LOCKNUT

WRENCH (Part No. HD-94660-37B) and a torque

wrench to tighten sprocket nut to 50 ft-lbs (68 Nm)

INITIAL torque, ONLY.

c. See Figure 6-66. Scribe a line on the transmission

sprocket nut and continue the line on the transmis-

sion sprocket as shown.

d. Tighten the transmission sprocket nut an additional

30°-40°.

e. See Figure 6-63. Install lockplate over nut so that

two of lockplate’s four drilled holes (diagonally oppo-

site) align with sprocket’s two tapped holes.

NOTE

The lockplate has four screw holes and can be turned to

either side, so you should be able to find a position without

having to additionally tighten the nut. If you cannot align the

screw holes properly, the nut may be additionally TIGHT-

ENED until the screw holes line up, but do not exceed 45° as

specified above. Never LOOSEN nut to align the screw holes.

f. See Figure 6-66. If lockplate will not align with holes,

tighten nut to 45° maximum.

CAUTION

Maximum allowable tightening of sprocket nut is 45° of

counterclockwise rotation, after initially tightening to 50

ft-lbs. Do not loosen sprocket nut while attempting to

align the screw holes. If you cannot align lockplate and

sprocket screw holes, nut may be additionally tightened

45° as specified above. Tightening too much or too little

may cause the nut to come loose during vehicle opera-

tion.

Figure 6-63. Transmission Sprocket

Figure 6-64. Sprocket Locking Tool

1. Main Drive Gear Shaft

2. Transmission Sprocket

3. Transmission Sprocket Nut (left-hand threads)

4. Lockplate

5. Socket Head Screw (2)

a0149x6x

1

2

3

4

5

7398

1. Sprocket Locking Tool (Part No. B-43982).

1

Loading...

Loading...