2002 Buell P3: Maintenance 1-27

HOME

SPARK PLUG 1.16

GENERAL

Change spark plug:

● At every 10,000 mile (16,000 km) service interval.

Use only Harley-Davidson No. 10R12 plug (Part No.

27661-00Y) as a replacement.

INSPECTION

1. Disconnect cable from both spark plug by pulling on rub-

ber boot (not cable).

2. Remove spark plug and examine.

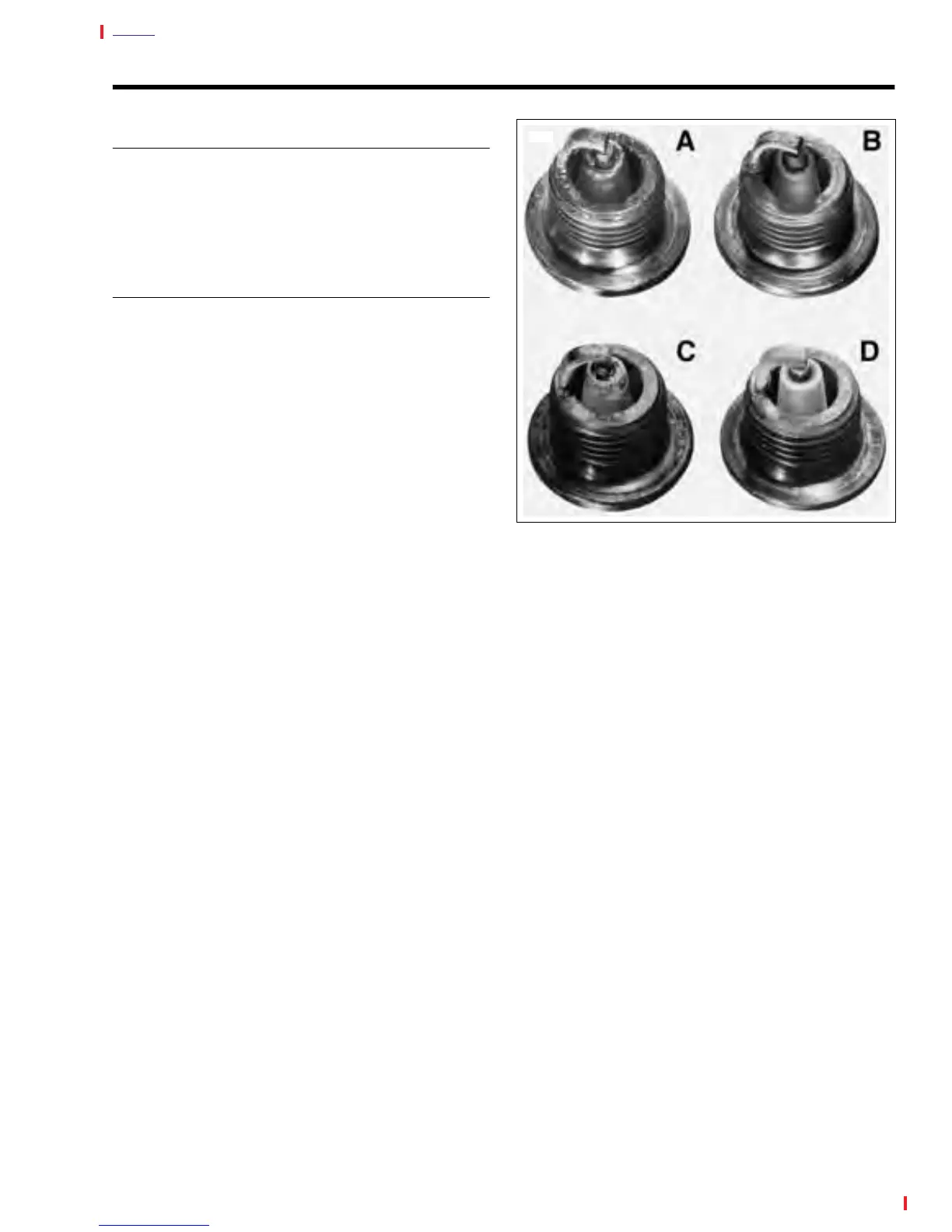

3. See Figure 1-34. Compare your observations of the plug

deposits with the descriptions provided below.

a. A wet, black and shiny deposit on plug base, elec-

trodes and ceramic insulator tip indicates an oil

fouled plug. The condition may be caused by one or

more of the following: worn pistons, worn piston

rings, worn valves, worn valve guides, worn valve

seals, a weak battery or a faulty ignition system.

b. A dry, fluffy or sooty black deposit indicates a carbu-

retor air-fuel mixture that is too rich, engine idling for

excessive periods of time and/or enrichener usage

for excessive periods of time.

c. A light brown, glassy deposit indicates an over-

heated plug. This condition may be accompanied by

cracks in the insulator or by erosion of the elec-

trodes and is caused by an air-fuel mixture that is

too lean, a hot-running engine, valves not seating or

improper ignition timing. The glassy deposit on the

spark plug is a conductor when hot and may cause

high-speed misfiring. A plug with eroded electrodes,

heavy deposits or a cracked insulator must be

replaced.

d. A plug with a white, yellow, tan or rusty brown pow-

dery deposit indicates balanced combustion. Clean

off spark plug deposits at regular intervals.

4. If the plug requires cleaning between tune-ups and

replacement plug is not available, proceed as follows:

a. De-grease firing end of spark plug using ELECTRI-

CAL CONTACT CLEANER. Dry plug with com-

pressed air.

b. Use a thin file to flatten spark plug electrode. A

spark plug with sharp edges on its electrodes

requires 25%-40% less firing voltage than one with

rounded edges.

5. If the plug cannot be cleaned, replace with HD No.

10R12 spark plug (Part No. 27661-00Y).

6. Check electrode gap with a wire-type feeler gauge. Gap

should be 0.038-0.043 in. (0.97-1.09 mm).

7. Apply LOCTITE ANTI-SEIZE to threads of spark plug.

Install and tighten to 11-18 ft-lbs (14.9-24.4 Nm).

8. Connect spark plug cable. Verify that cable is securely

connected to ignition coil and spark plug.

Figure 1-34. Typical Spark Plug Deposits

4636

Loading...

Loading...