5-12 2002 Buell P3: Electric Starter

HOME

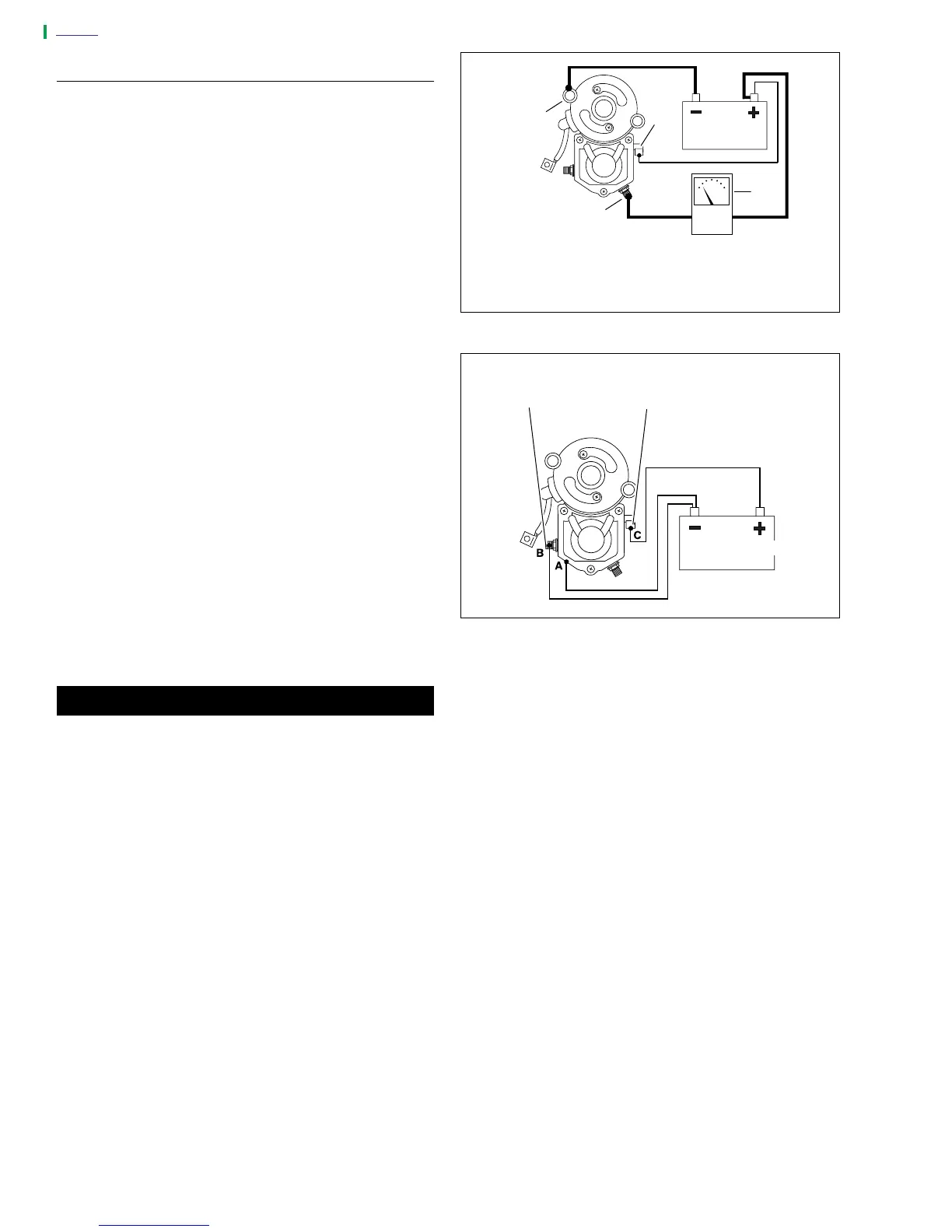

TESTING ASSEMBLED STARTER

Free Running Current Draw Test

1. Place starter in vise, using a clean shop towel to prevent

scratches or other damage.

2. See Figure 5-12. Attach one heavy jumper cable (6

gauge minimum).

a. To the starter mounting flange (1).

b. To the negative (-) terminal of a fully charged bat-

tery.

3. Connect a second heavy jumper cable (6 gauge mini-

mum).

a. To the positive (+) terminal of the battery.

b. To an inductive ammeter (2). Continue on to the bat-

tery terminal (3) on the starter solenoid.

4. Connect a smaller jumper cable (14 gauge minimum).

a. To the positive (+) terminal of the battery.

b. To the solenoid relay terminal (4).

5. Check ammeter reading.

a. Ammeter should show 90 amps maximum.

If reading is higher, disassemble starter for inspection.

b. If starter current draw on vehicle was over 130 amps

and this test was within specification, there may be a

problem with engine or primary drive.

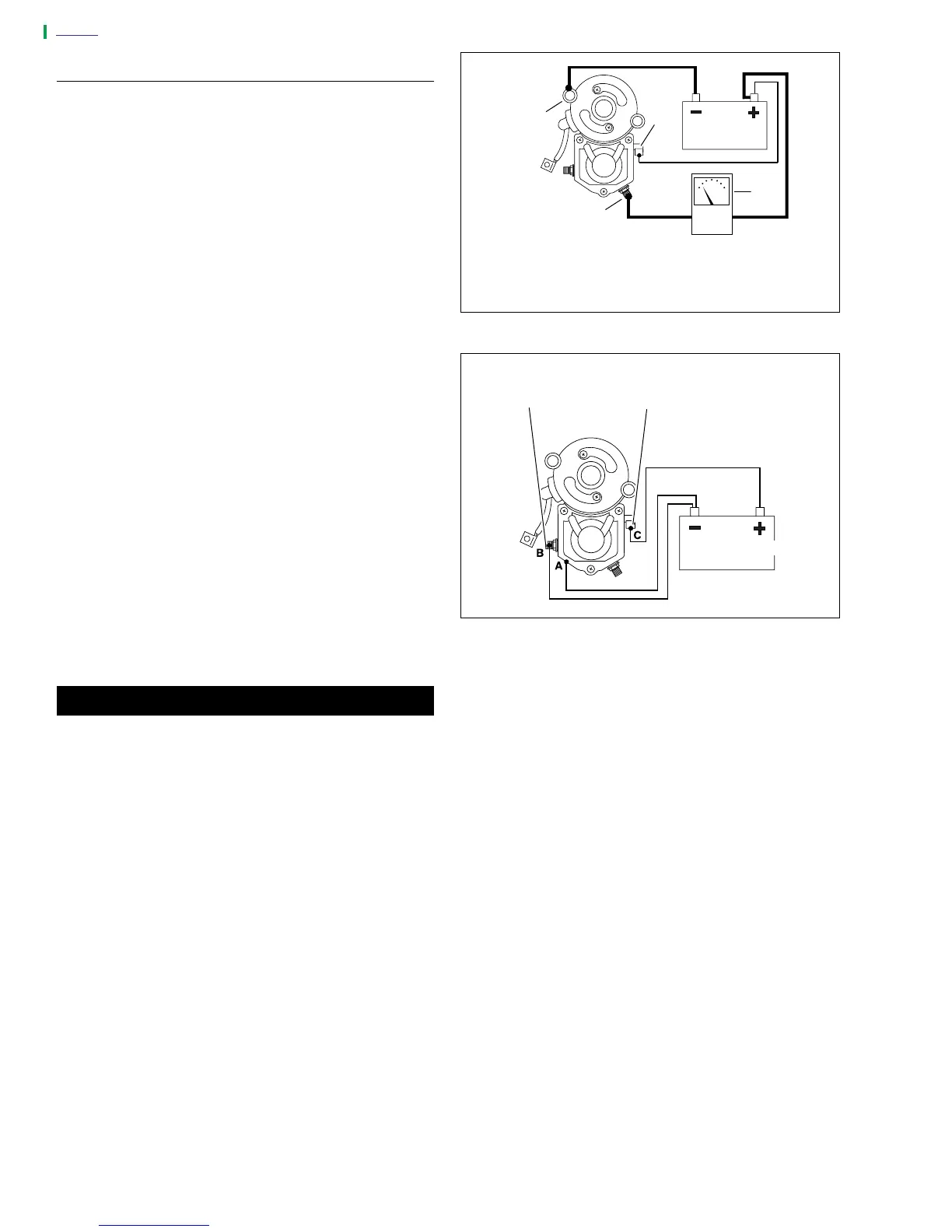

Starter Solenoid

NOTE

Do not disassemble solenoid. Before testing, disconnect field

wire from motor terminal as shown in Figure 5-13.

CAUTION

Each test should be performed for only 3-5 seconds to

prevent damage to solenoid.

NOTE

The solenoid Pull-in, Hold-in, and Return tests must be per-

formed together in one continuous operation. Conduct all

three tests one after the other in the sequence given without

interruption.

Solenoid Pull-in Test

1. See Figure 5-13. Using a 12 volt battery, connect three

separate test leads as follows:

a. Solenoid housing to negative battery post.

b. Solenoid motor terminal to negative battery post.

c. Solenoid relay terminal to positive battery post.

2. Observe starter pinion.

a. If starter pinion pulls in strongly, solenoid is working

properly.

b. If starter pinion does not pull in, replace the sole-

noid.

Figure 5-12. Free Running Current Draw Test

Figure 5-13. Pull-In Test

1. Mounting Flange

2. Induction Ammeter

3. Battery Terminal

4. Relay Terminal

a0168x5x

1

3

2

4

Battery

Battery

a0169x5x

Motor Terminal

Relay Terminal

Loading...

Loading...