4-26 2002 Buell P3: Fuel System

HOME

INSTALLATION

1. Obtain new throttle position sensor. If old sensor is used,

inspect O-ring for cuts, tears or signs of deterioration.

Replace O-ring if necessary. See Figure 4-24.

2. Align holes in throttle position sensor with those in carbu-

retor housing. Using special TORX bit (Snap-on®

TTXR20E), loosel

y install two tamper-resistant T20

TORX screws.

NOTE

The tamper-resistant screws are not to be tightened until the

throttle position sensor has been properly adjusted. See the

instructions under step 6 for details.

3. Locate 6-place Deutsch connector and install pin termi-

nals in chambers 3 through 5. Mate pin and socket

halves of connector.

NOTE

For instructions on properly installing wire terminals, see

Appendix B.

4. Insert bolt through battery negative cable (black) into

threaded hole of battery negative (-) terminal. Tighten

bolt to 60-96 in-lbs (7-11 Nm).

5. Standing on the right side of the vehicle, start air box into

opening. When partially installed, push PCV outlet hose

onto middle fitting of 3-way connector, and loosely install

carburetor onto manifold-carburetor coupler.

6. Adjust throttle position sensor as follows:

a. Back off idle adjustment screw so throttle plate is

fully closed.

b. Completely open and close the throttle by rotating

the throttle control through its full range of motion.

c. Using special TORX bit (Snap-on® TTXR20E),

loosen the two tamper-resistant T20 TORX screws

just enough to allow sensor to rotate.

d. Disconnect pin 3 in connector [88B] (main wire har-

ness).

e. Install Breakout Box Adaptors (HD-42962) and

Breakout Box (HD-42682) using black connectors

between connector halves [88A] and [88B].

f. Turn ignition switch to ON. Using a multimeter, mea-

sure voltage between pin 3 (V/W) and pin 5 (BK).

g. Adjust (rotate) throttle position sensor (TPS) until

voltage reading is 0.5V +/- 0.05V.

h. Completely open and close the throttle by rotating

the throttle control through its full range of motion.

Wide Open Throttle (WOT) should not exceed 3.7V

and reading should increase consistently as throttle

is opened. If the voltage reading is erratic or the volt-

age reading at WOT exceeds 3.7V see Figure 7-10.

for diagnostic testing.

NOTE

After WOT, the TPS reading may not return back to exactly

0.5V +/- 0.05V. To re-check exact TPS voltage reading, turn

cycle key off and on.

i. Tighten TP Sensor mounting screws to 13-23 in-lbs

(2-3 Nm).

7. Moving to opposite side of vehicle, apply a small dab of

Loctite Low Strength Threadlocker 222 (Purple) to

threads of two flange bolts. Slide bolts through top two

holes of triangular bracket and install into left side of air

box. Alternately tighten screws to 3-5 ft-lbs (4-7 Nm).

8. Returning to the right side of the vehicle, fix position of

carburetor on manifold-carburetor coupler. Turn slotted

screw to tighten band clamp on outboard side of coupler.

9. Apply one drop

of Loctite High Strength Threadlocker

262 (red) to threads of hex screw. Install screw at bottom

of air box (6 o’clock position) to secure air box bracket to

crankcase hole. Tighten screw to 10-12 ft-lbs (14-16

Nm).

10. Taking note of index pin on inboard side of cover and

small depression at tip of cone, position cover onto air

box so that pin engages depression.

11. Lock five latches around perimeter of air box cover.

12. Install Phillips screw at bottom of air box cover (7 o’clock

position) to secure cover to air box. Tighten screw to 4-6

in-lbs (0.5-0.7 Nm).

13. Position seat on frame backbone, so that tongue at bot-

tom engages slot in frame weldment. Push down on rear

of seat until spring-loaded latch fully engages groove of

seat pin.

11WARNING1WARNING

Pull up on seat to verify that it is properly secured, front

and rear. A loose seat may shift during vehicle operation

and startle the rider, possibly causing loss of vehicle

control that could result in death or serious injury.

14. Adjust engine idle speed, as follows:

NOTE

Be sure the engine is warmed up to normal operating temper-

ature BEFORE adjusting engine idle speed.

a. With the engine at normal operating temperature

(auto-enrichener valve closed), adjust the throttle

stop screw so the engine idles at 1200 rpm.

NOTE

To measure engine rpm, use a hand held inductive tachom-

eter (Snap-on® ONO-SE-1100) to pick up the signal off the

spark plug cable.

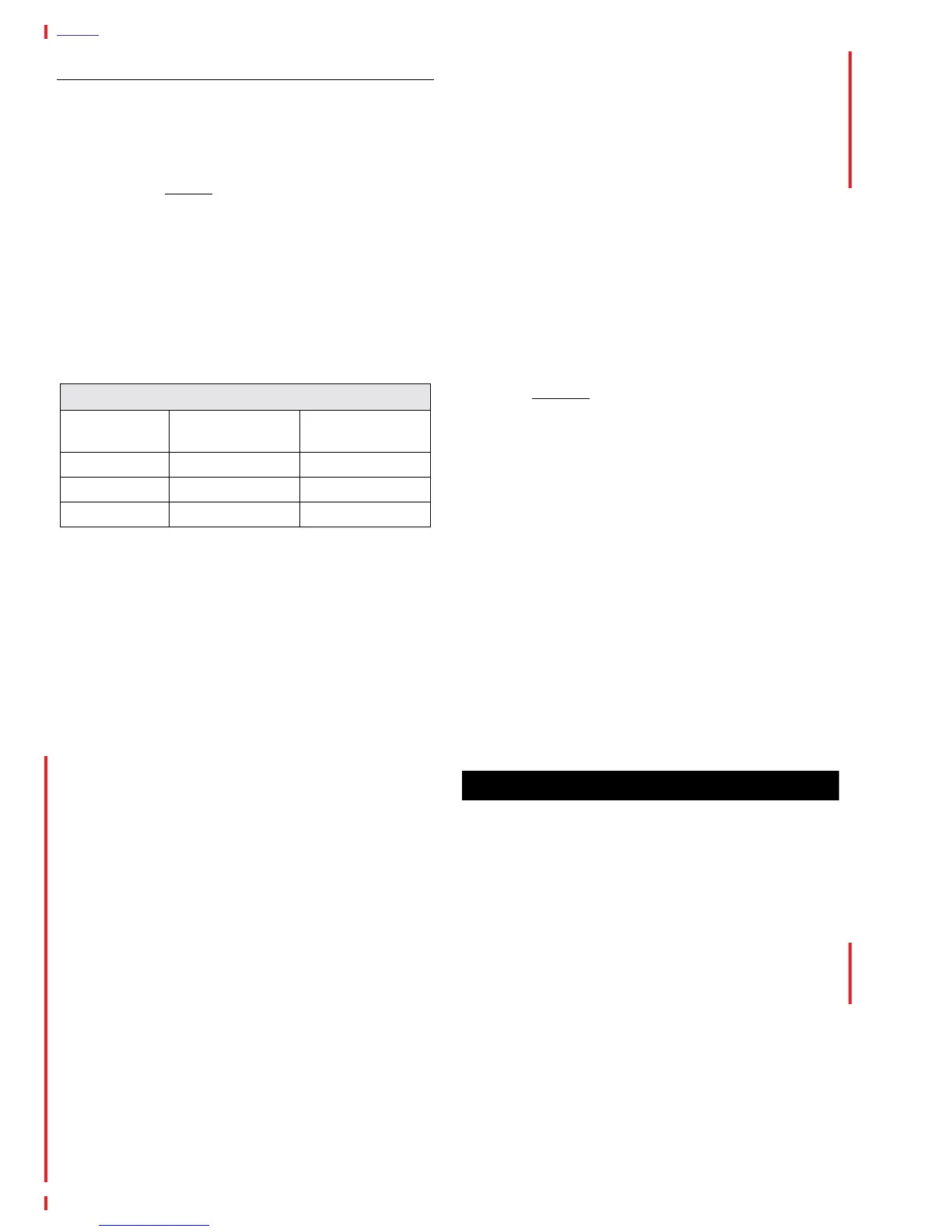

Throttle Position Sensor Connector

Chamber

Number

Wire Color Function

3Light Blue Output

4Yellow Input

5Black Ground

Loading...

Loading...