2002 Buell P3: Electric Starter 5-15

HOME

NOTE

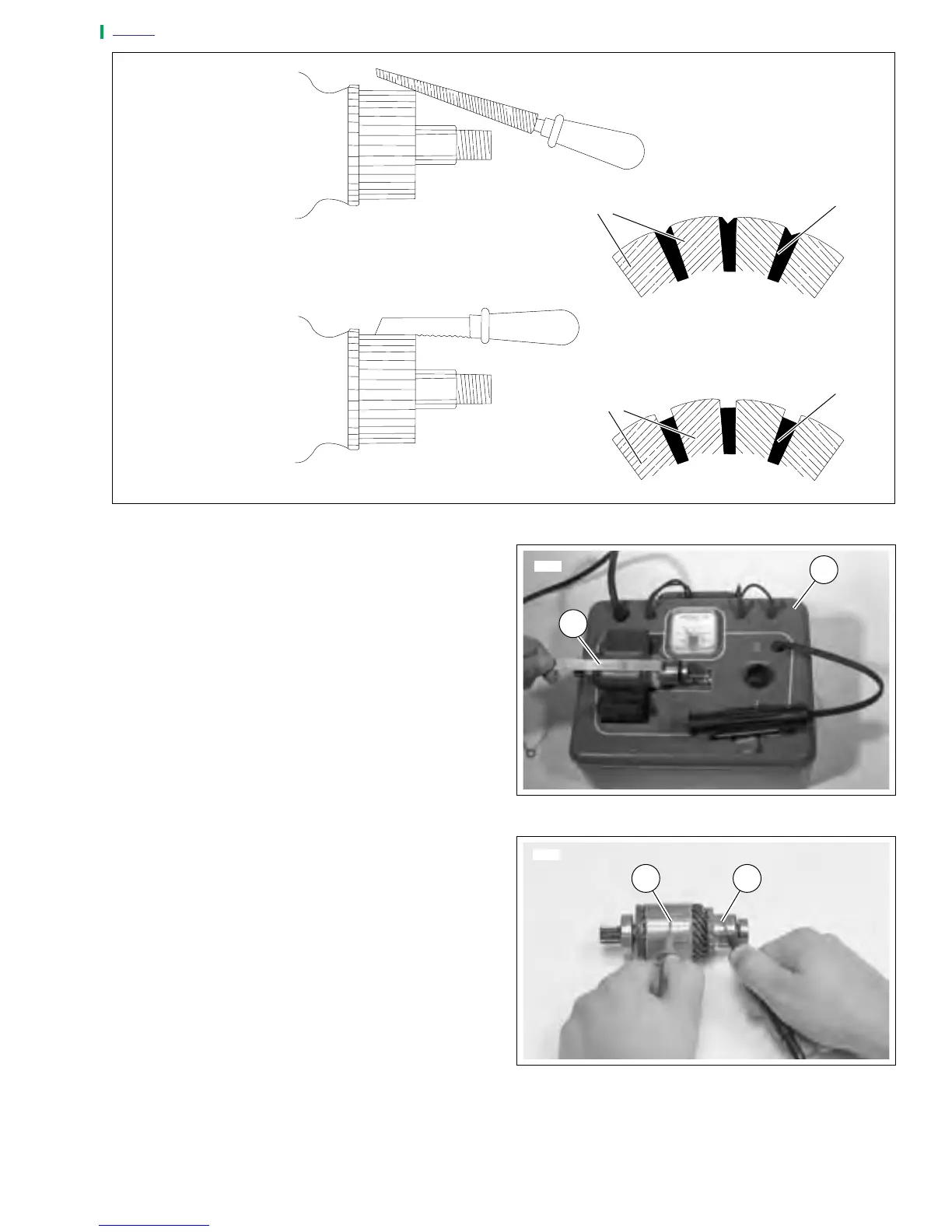

See Figure 5-19. If an undercutting machine is not available,

undercutting can be done satisfactorily using a thin hacksaw

blade. After undercutting, lightly sand the commutator with

crocus cloth to remove any burrs.

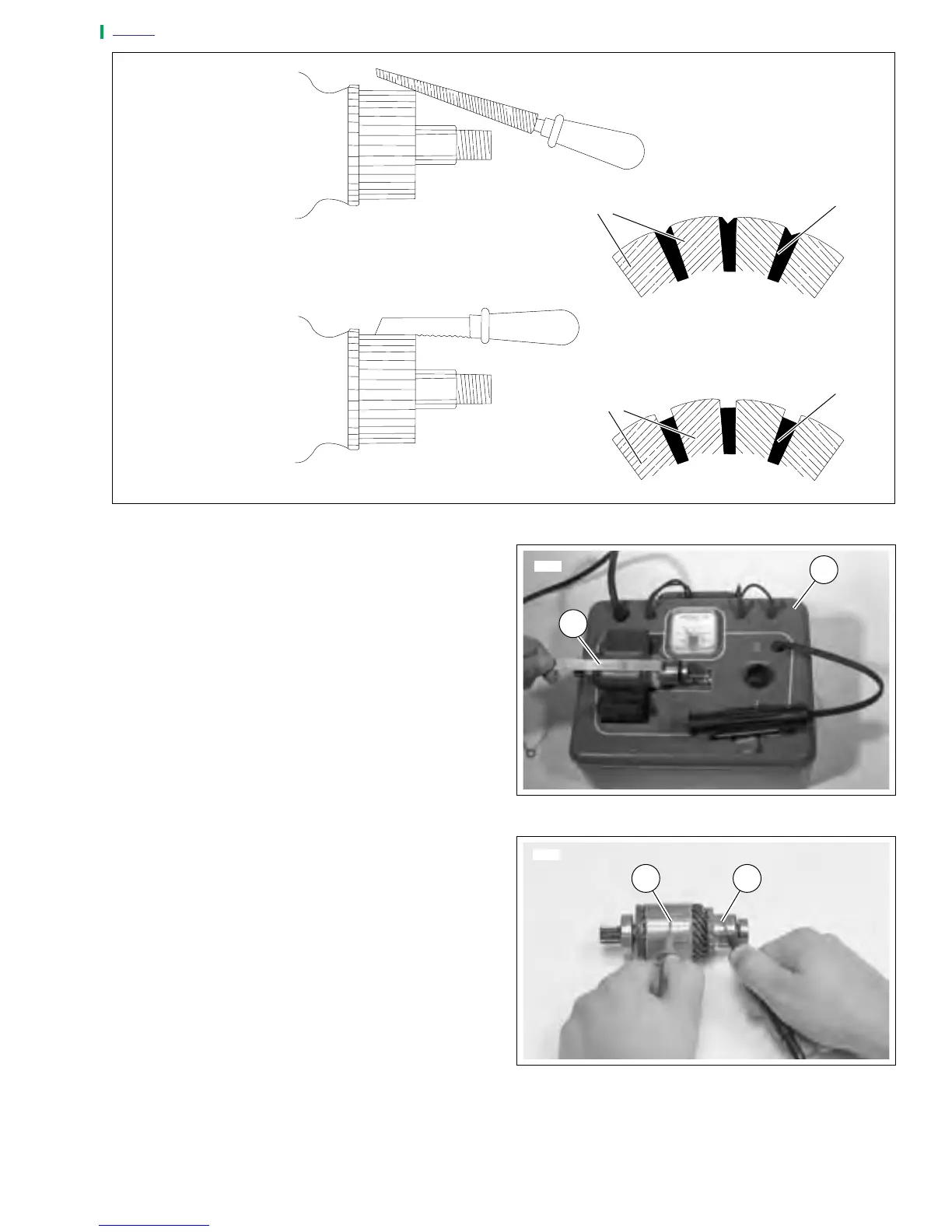

9. See Figure 5-20. Check for SHORTED ARMATURE with

a growler.

a. Place armature on growler (1).

b. Hold a thin steel strip (2) (hacksaw blade) against

armature core and slowly turn armature.

c. A shorted armature will cause the steel strip to

vibrate and be attracted to the core. Replace

shorted armatures.

10. See Figure 5-21. Check for a GROUNDED ARMATURE

with an ohmmeter or continuity tester.

a. Touch one probe to any commutator segment (1).

b. Touch the other probe to the armature core (2).

c. There should be no continuity (infinite ohms). If

there is continuity, then the armature is grounded.

Replace grounded armatures.

Figure 5-19. Undercutting Mica Separators

Mica must not be left with a

thin edge next to segments

Right way

Mica

Undercutting mica with

piece of hacksaw blade

Wrong way

Starting groove in mica

with 3 cornered file

Mica must be cut away

clean between segments

a0188x5x

Mica

Segments

Segments

Figure 5-20. Shorted Armature Test Using Growler

Figure 5-21. Grounded Armature Test

1782a

1

2

6011

12

Loading...

Loading...