6-34 2002 Buell P3: Drive/Transmission

HOME

DISASSEMBLY

Drive out needle bearings from inside bore of main drive

gear. Do not reuse bearings after removal.

ASSEMBLY

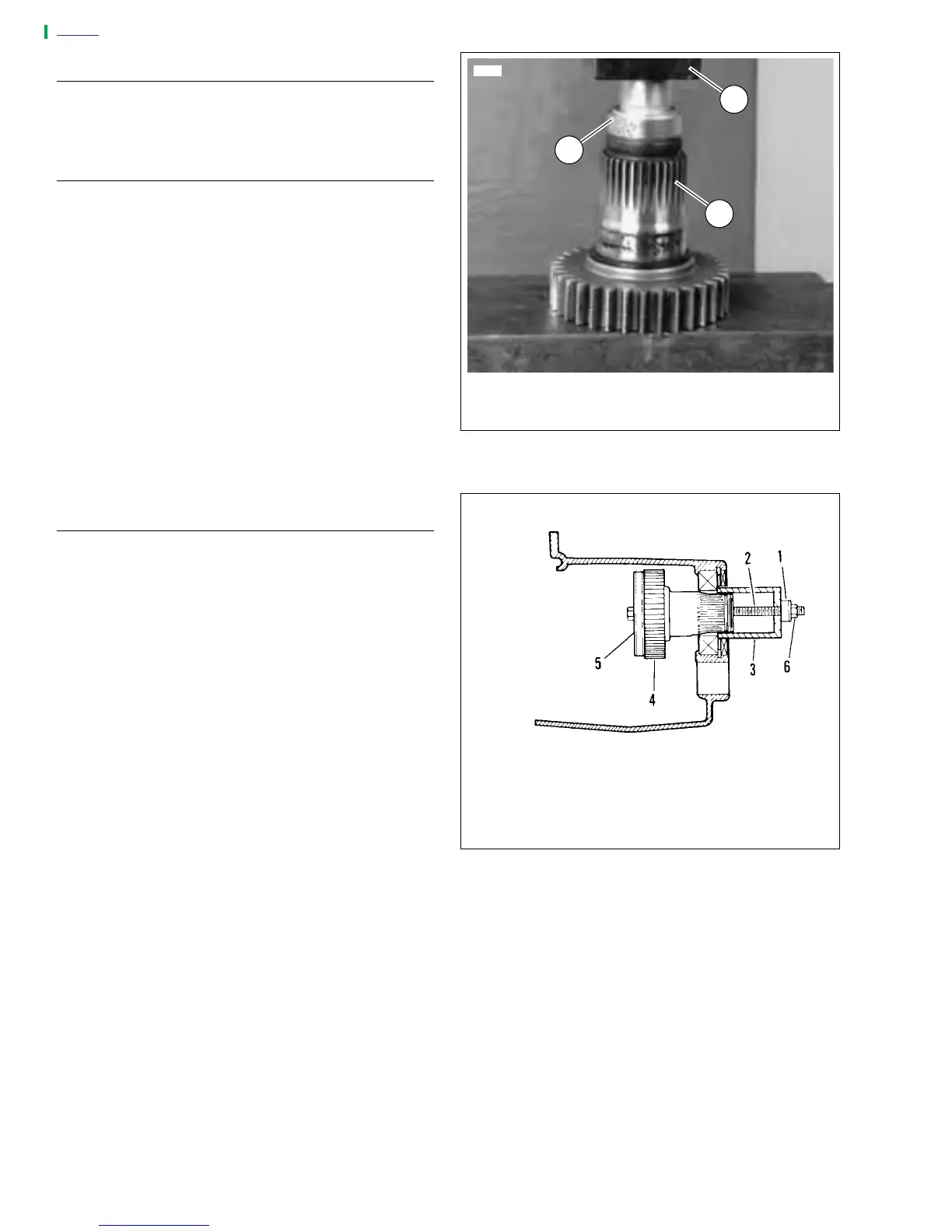

1. See Figure 6-48. Use INNER/OUTER MAIN DRIVE

GEAR NEEDLE BEARING INSTALLATION TOOL (Part

No. HD-37842-A) for assembly. Select which end of tool

to use.

a. The end stamped 0.080 in. (2.032 mm) is for driving

the bearing into the inner end.

b. The end stamped 0.315 in. (8.001 mm) is for the

outer end bearing.

2. Assemble parts. The installation tool will automatically

bottom on the gear when the correct depth is reached.

a. Place main drive gear on a press.

b. Press in the outer bearing to a depth of 0.315-0.285

in. (8.001-7.239 mm).

c. Press in the inner bearing to a depth of 0.080 in.

(2.032 mm).

INSTALLATION

1. Replace main drive gear bearing.

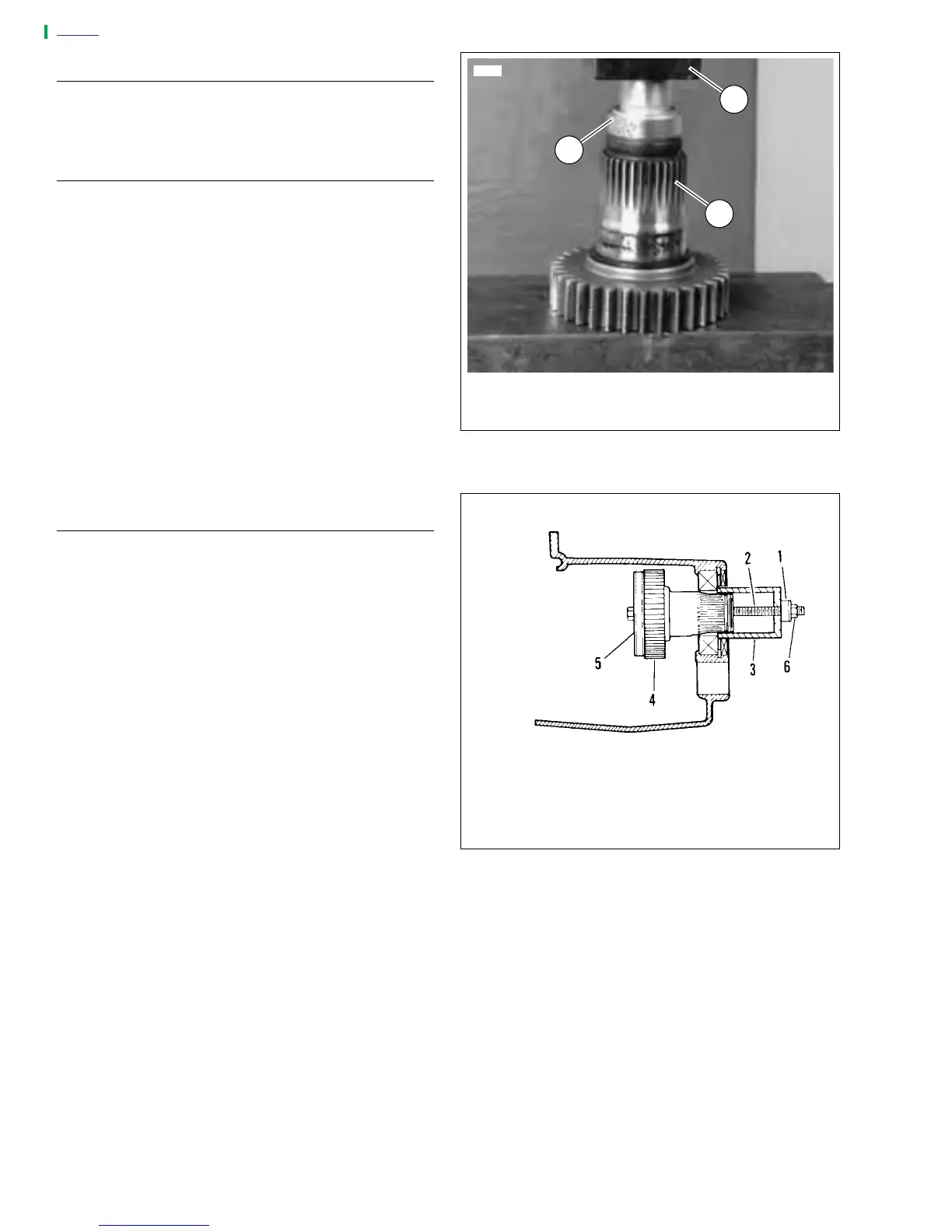

2. See Figure 6-49. Use MAIN DRIVE GEAR REMOVER

AND INSTALLER (Part No. HD-35316-A) for assembly.

a. Take bolt (2) and place washer (5) followed by main

drive gear (4) over end of bolt.

b. From inside of case insert bolt and main drive gear

through inner race of ball bearing.

c. Insert threaded end of bolt (2) through installer cup

(3) and thrust washer (1).

d. Thread nut (6) onto end of bolt (2). Tighten nut (6)

until shoulder on gear (4) bottoms against inner race

of bearing.

3. See Figure 6-45. Tap in

new

seal (3) at threaded end of

5th gear.

Figure 6-48. Needle Bearing Installation Tool

Figure 6-49. Main Drive Gear Installation

3554

1

1. Ram on End of Press

2. Needle Bearing Installation Tool

3. Main Drive Gear

3

2

1. Thrust Washer

2. Bolt

3. Installer Cup

4. 5th Gear

5. Washer

6. Nut

a0122xSx

Loading...

Loading...