7-MAINTENANCE

Checkingforcylinderleakage

Acylinderrodshouldbeslightlyoily.Checkthatthereare

noleaksafteraperiodofwork,whenthewholehydraulic

systemisatnormaloperatingtemperature.

1.Wipetherodandbearingcleanonthecylindertobe

checked.

2.Operatenormallyforveortenminutes.

3.Extendthecylinderrod.

4.Carryouttheleaktest.

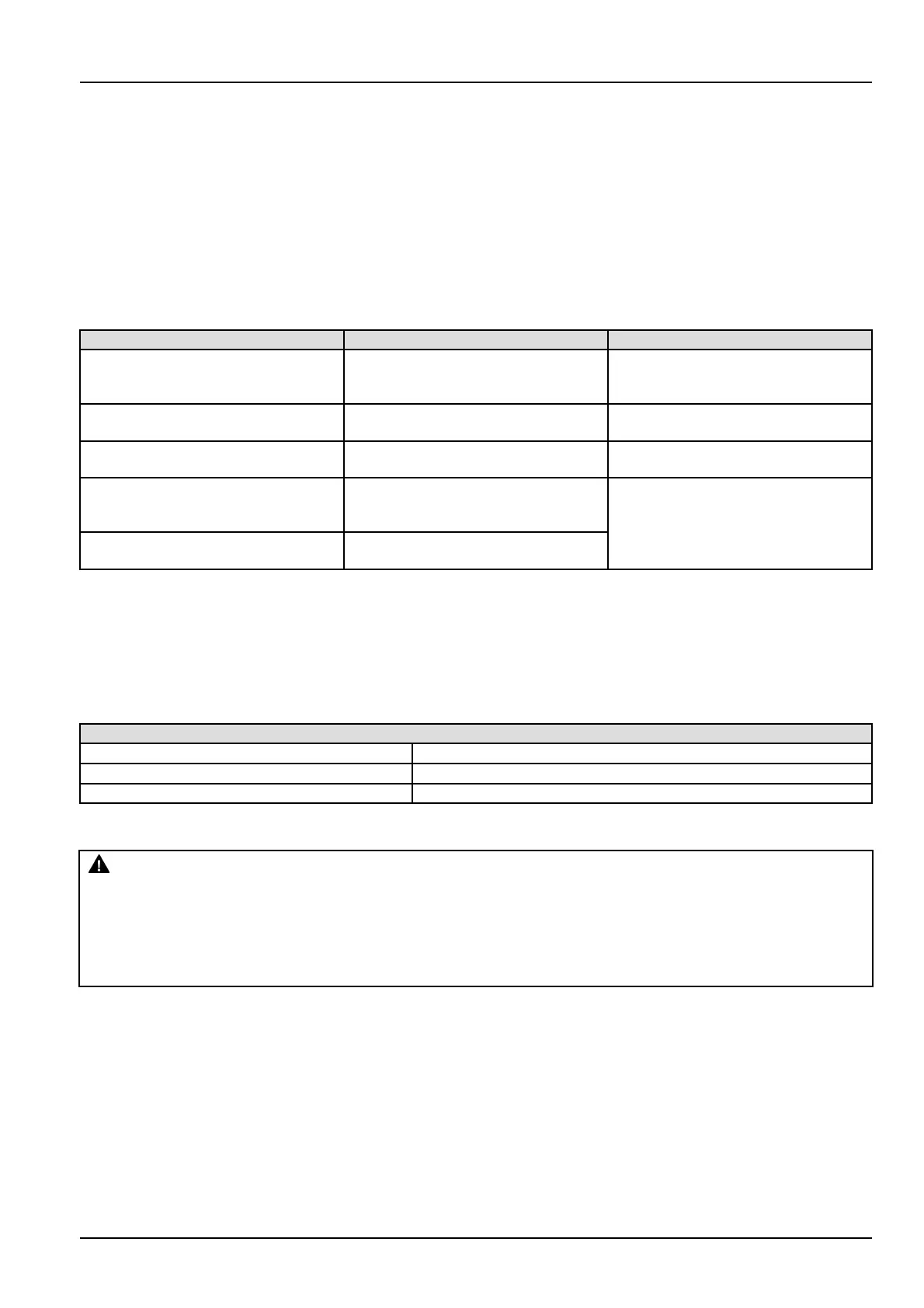

RodAppearanceTest

Conclusion

Dry

Slighttracesofoilwhenapieceof

paperiswipedover20cm(7.9in)of

therod.

Normal

Slightlygreasy

Paperremainsstucktorodwhenrun

overrod.

Normal

Oily

Paperremainsstuckwhenplacedon

rod.

Normal

Veryoilyorweeping

Eachtimethecylinderrodis

extended,aringofoilcanbeseen

ontherod.

Leakage

Eachtimetherodretracts,theexcess

oildripsfromthegland.

Seeyourdealer

Fireextinguisher(notsupplied)

Itisstronglyrecommendedareextinguisherbekepton

themachine.Anextinguisherisnotsuppliedbutcanbe

purchasedseparatelyandplacedintherearleft-handside

compartment.Aspecicbrackethasbeenprovidedforthis

purpose.

Maintenancespecications

Everymonth

Examinethereextinguisherandmakesureitisnotdamaged.

Everysixmonths

Haveanapprovedspecialistemptyandrellthereextinguisher.

Everyyear

Haveanapprovedspecialistexaminethereextinguisher.

Weldingonthemachine

DANGER

Improperoperationorserviceofthismachinecanresultinanaccident.

Anyunauthorizedmodicationsmadetothismachinecanhaveseriousconsequences.Consultan

authorizeddealeronchanges,additions,ormodicationsthatmayberequiredforthismachine.Do

notmakeanyunauthorizedmodications.

Failuretocomplywillresultindeathorseriousinjury.

D0030A

Whenevercarryingoutaweldingoperationonthemachine

asauthorizedbythemanufacturerandinaccordancewith

manufacturer’sinstructions,disconnectthebatteries,dis-

connectthealternatorB+andD+terminalwires,andcon-

necttheweldingapparatusgroundcabletothecomponent

onwhichtheweldingoperationistobeperformed.

Alwaysconnecttheweldingapparatustothesamestruc-

turethatisbeingwelded.

Neverconnecttheweldingapparatusgroundtoacompo-

nentofthehydraulicsystem.

7-97

Loading...

Loading...