M-Series Operator’s Manual 4/9/15

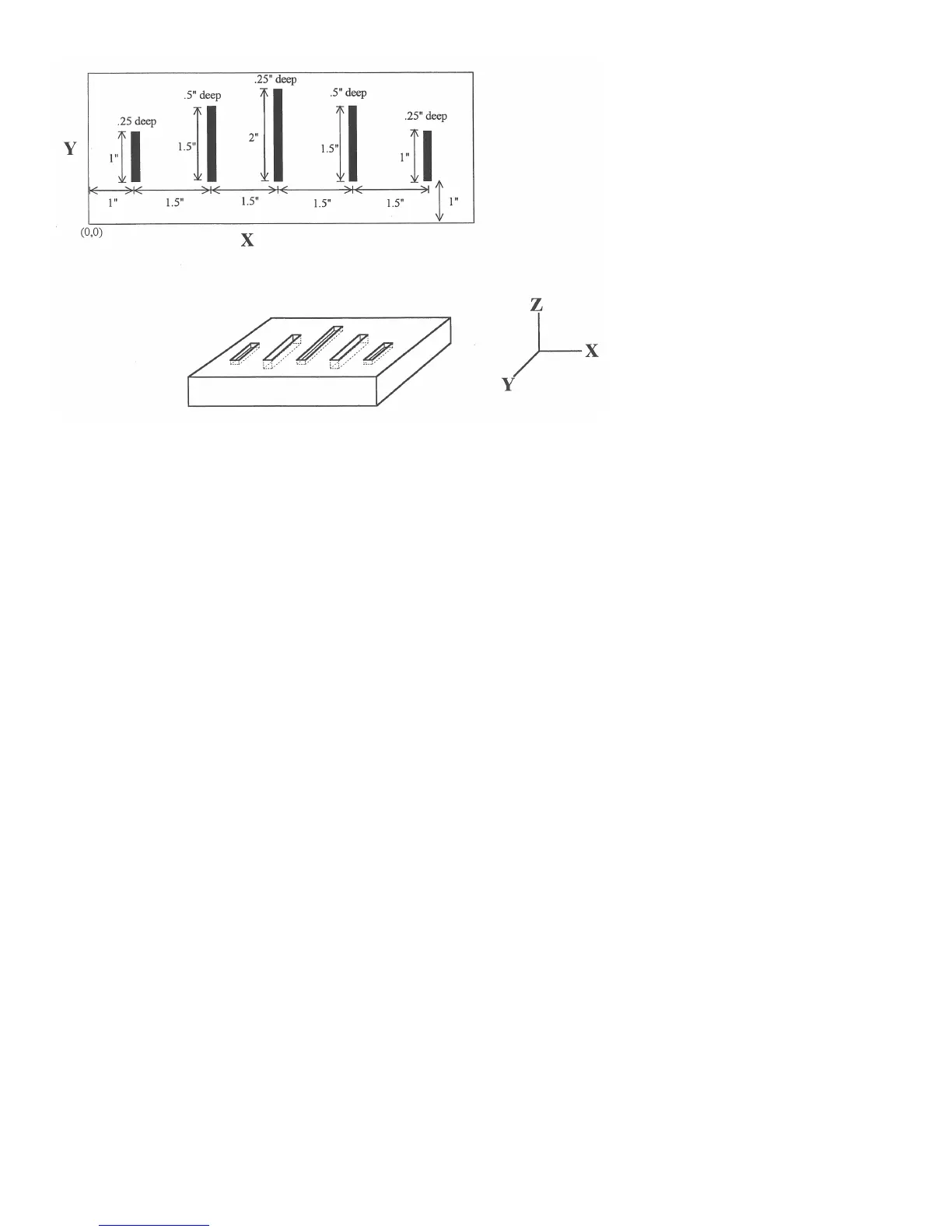

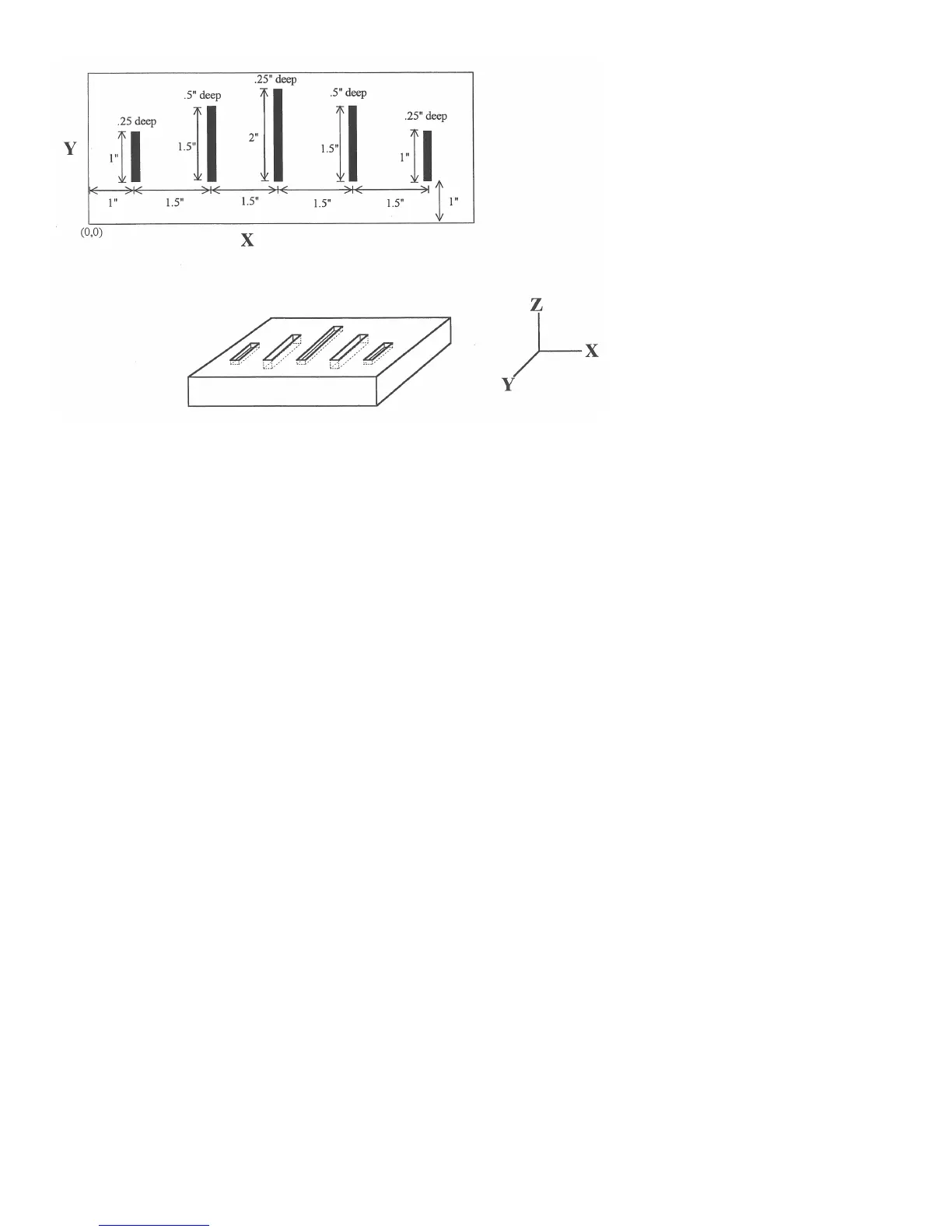

The macro variables would handle the length in the Y direction and depth in the Z direction:

O0002

G90 G1 Z0 F30 ; Linear move to Z0

Z#Z F5 ; Cut to variable depth

G91Y#Y F10 ; Cut variable length

G90 G0 Z0.1 ; Retract

The main program would call this macro five times, each time specifying the depth and length required.

: Main Program

G90 G0 X1 Y1 Z0.1 ; Move to first notch

G65 P0002 L1 Y1 Z.25 ; Call macro and assign Y=1" and Z=.25"

G90 G0 X2.5 Y1 ; Move to second notch

G65 P0002 L1 Y1.5 Z.5 ; Call macro and assign Y=1.5" and Z=.5"

G90 G0 X4 Y1 ; Move to third notch

G65 P0002 L1 Y2 Z.25 ; Call macro again

G90 G0 X5.5 Y1 ; Move to fourth notch

G65 P0002 L1 Y1.5 Z.5 ; Call macro again

G90 G0 X7 Y1 ; Move to fifth notch

G65 P0002 L1 Y1 Z.25 ; Call macro again

: End program

G68, G69 - Coordinate Rotation on/off

G68 rotates program G-codes a specified angle R. G68 rotates all positions, lines, and arcs until a G69 is entered.

The center of rotation can be specified by X, Y and Z values (X, Y for G17 plane). If the center is not specified

then a default center of rotation is used as determined by machine parameter #2 (see Chapter 14 for parameter #2).

The default plane of rotation is G17 (X, Y).

Loading...

Loading...