AX-Series Motion Controller Instructions Manual Chapter 2

380

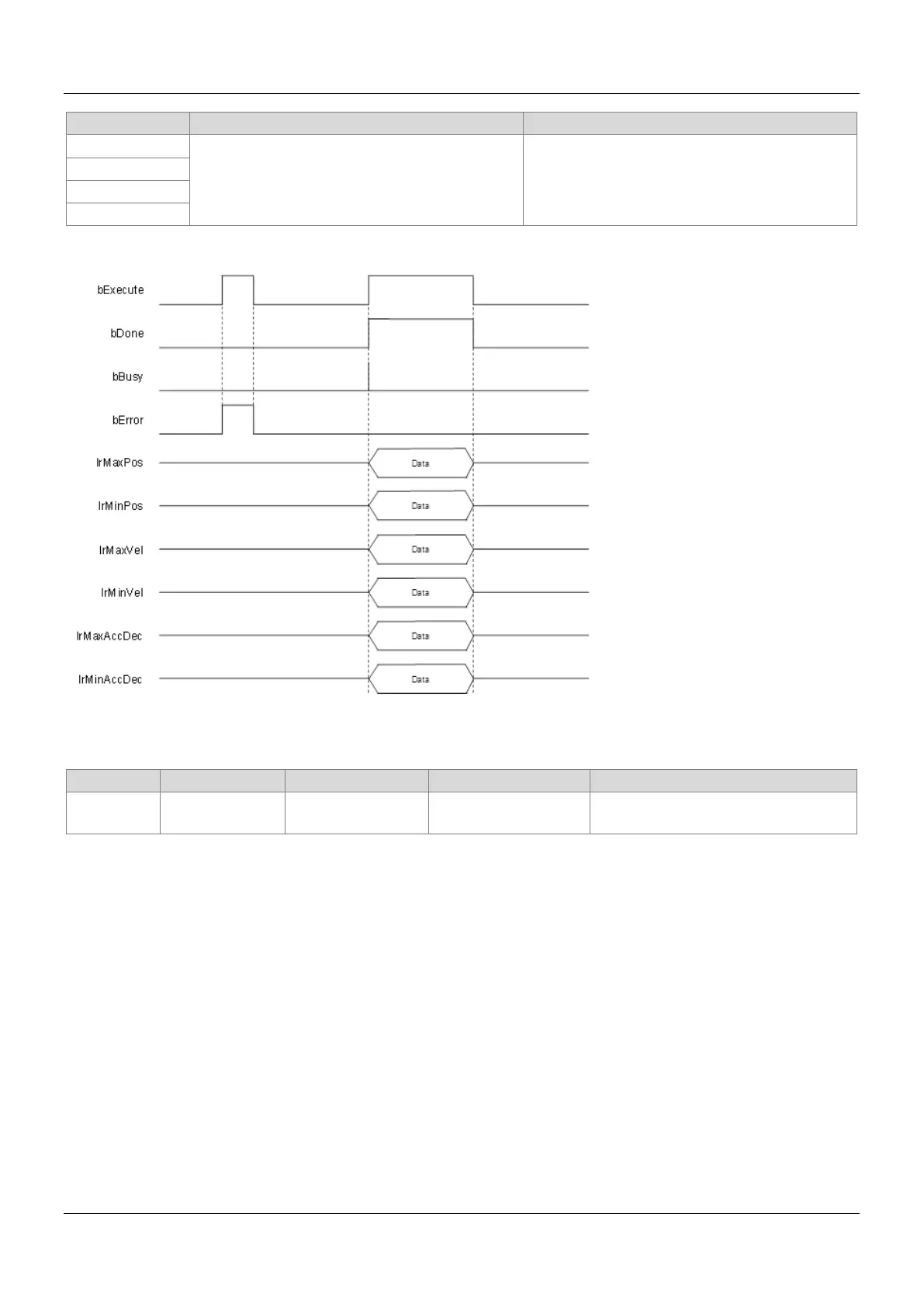

Timing for shifting to True

Timing for shifting to False

dMaxVel

dMinAccDec

Timing Diagram

Inputs/Outputs

CamTable

Specify cam

MC_CAM_REF

*

MC_CAM_REF

When bExecute is True.

*Note: MC_CAM_REF (FB): Basic cam.

Function

DMC_CAMBounds is used to check whether the user-defined cam table curve is correct. Use the maximum velocity,

acceleration and decelaration limit of the master axis to calculate the maximum (minimum) position, deceleration, and

acceleration of the slave axis.

This function block supports the following two cam formats:

XYVA

Two dimensional point array

Troubleshooting

When an error occurs during the execution of the instruction, bError changes to True. To confirm current error state,

see the error code in ErrorID.

Example

Loading...

Loading...