AX-Series Motion Controller Instructions Manual Chapter 2

53

The calculation for axis position and meshing position on cam coordinate:

Position_Slave = SlaveScaling×CAM (MasterScaling×MasterPosition + MasterCompensation) + SlaveCompensation

Slave meshing position = 1 × CAM (2 × 321(master position while executing CamIn) + 30) + 100

= 1 × CAM (672) + 100 = 1 × CAM (312) + 100

= 36 + 100

= 136

When meshing is completed, the master position will be at 321 and the slave position is at 136.

Example 2: The operation of tappet after configuring TappetHysteresis as the following example demonstrates.

Tappets

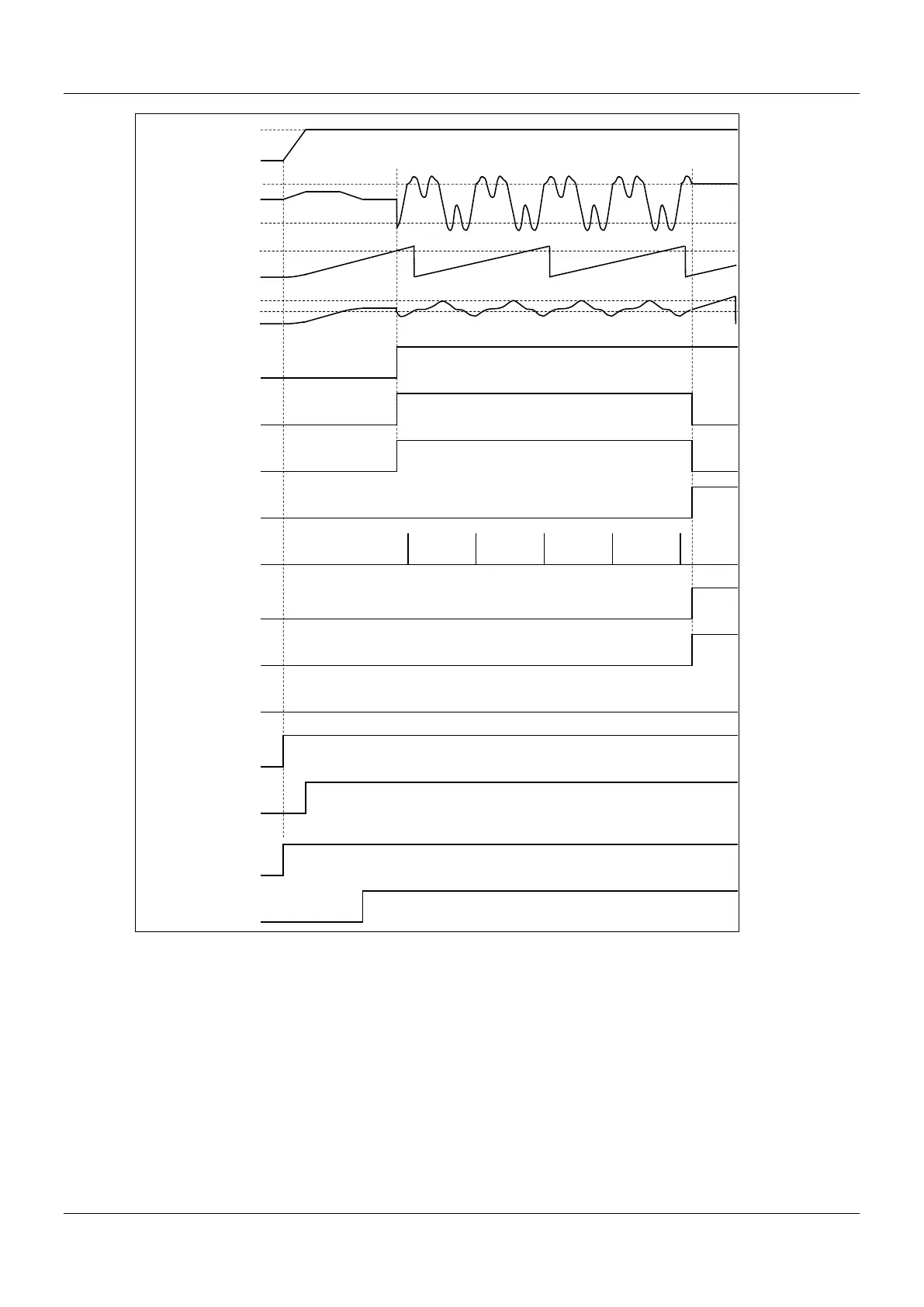

Loading...

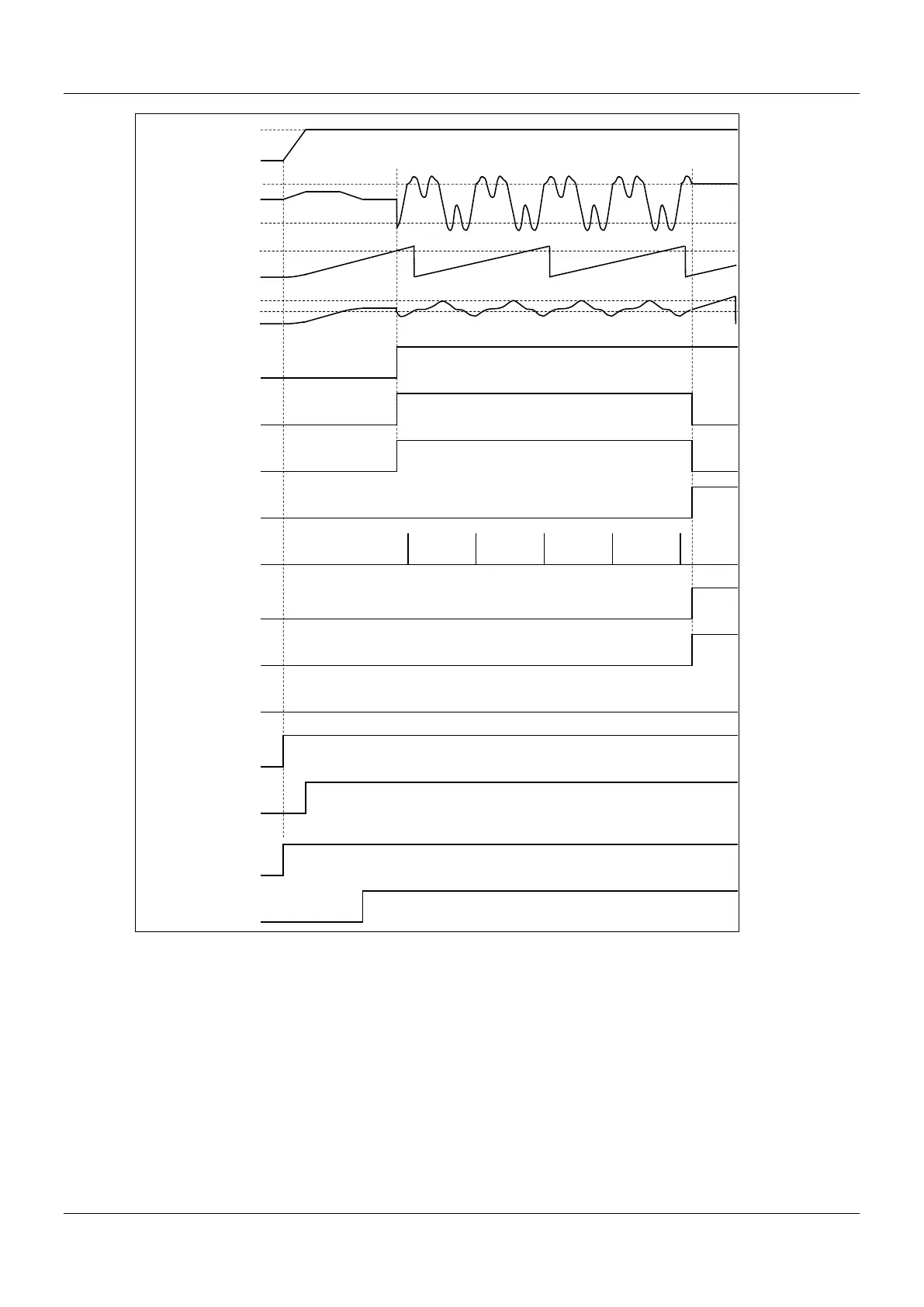

Loading...