AX-Series Motion Controller Instructions Manual Chapter 2

89

*Note: A negative gear ratio will make the master and slave axis move in an opposite direction.

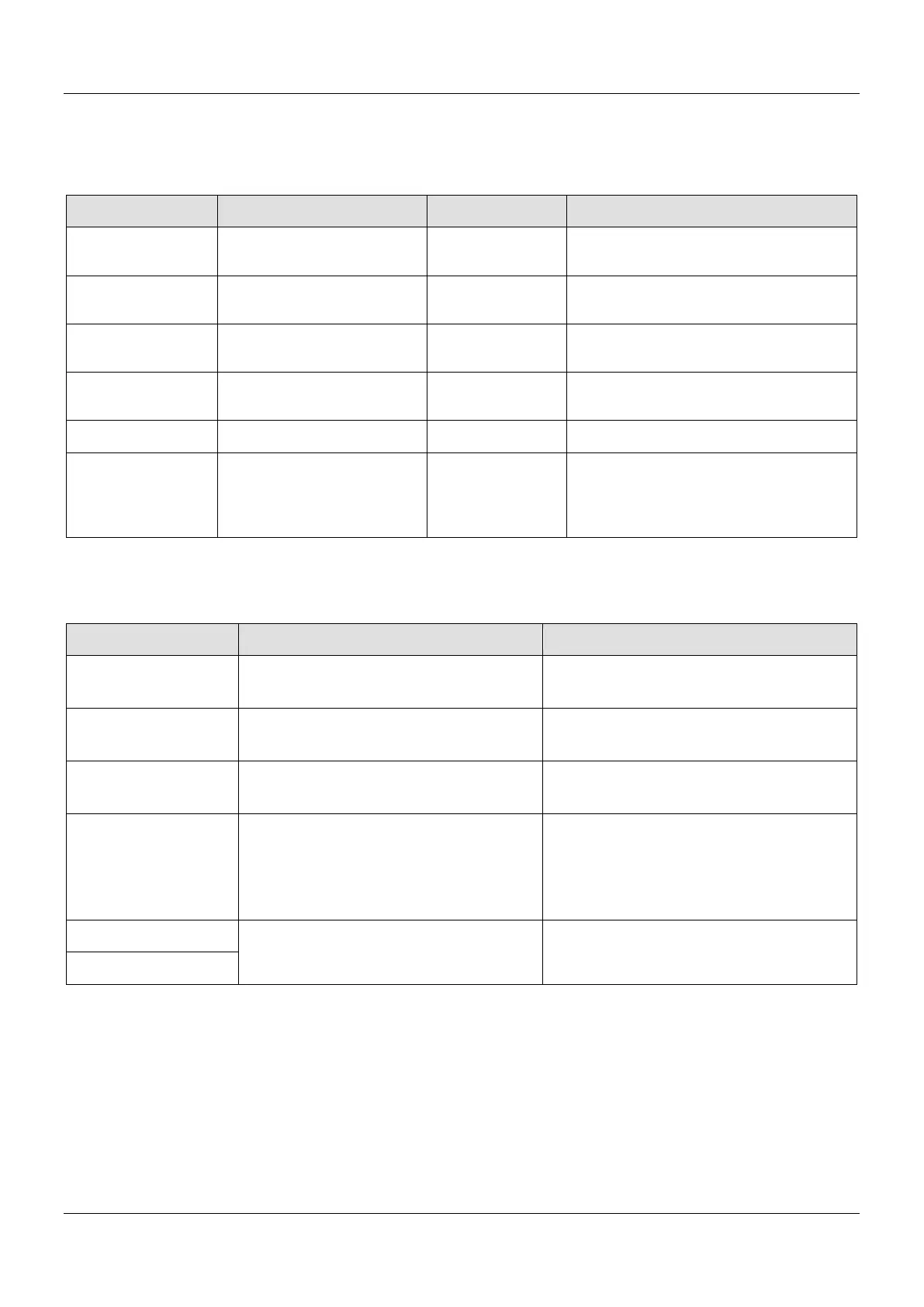

Outputs

Name Function Data Type Output Range (Default Value)

StartSync

True when the synchronization

BOOL True/False (False)

InSync

True when the synchronization

BOOL True/False (False)

Busy

True when the instruction is

BOOL True/False (False)

CommandAborted

True when the instruction is

BOOL True/False (False)

Error True when an error occurs. BOOL True/False (False)

ErrorID

Record the error code when an

error occurs.

Refer to Appendix for error

code descriptions.

SMC_ERROR* SMC_ERROR (SMC_NO_ERROR)

*Note: SMC_ERROR: Enumeration (Enum)

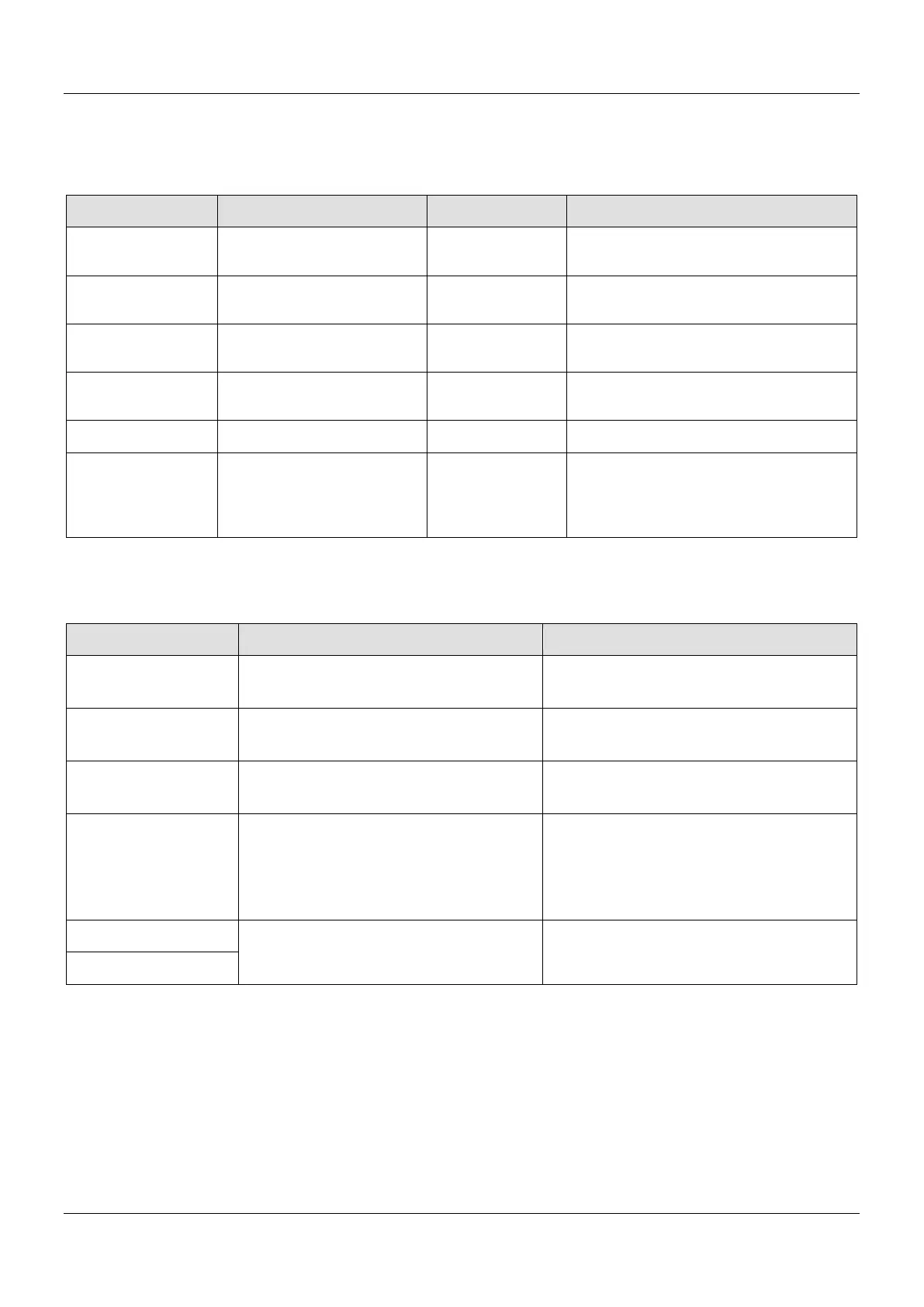

Output Updating Time

Timing for Shifting to True

Timing for Shifting to False

StartSync

When master axis travels to the start

position.

When InSync turns to True.

When Error turns to True.

InSync

When the synchronization between

master and slave axis is completed.

When CommandAborted turns to True.

When Error turns to True.

Busy After the synchronization begins.

When CommandAborted turns to True.

When Error turns to True.

CommandAborted

When MC_GearOut is run.

True when the instruction is aborted by

another function block.

When this instruction is aborted because

of the execution of MC_Stop instruction.

When Execute changes to False.

If Execute is False and CommandAborted

turns to True, CommandAborted will be

True for only one scan cycle and

immediately shift to False.

Error When an error occurs in the execution

conditions or input values for the

instruction.

When Execute turns from True to False.

(Error Code is cleared)

ErrorID

Timing Diagram

Loading...

Loading...