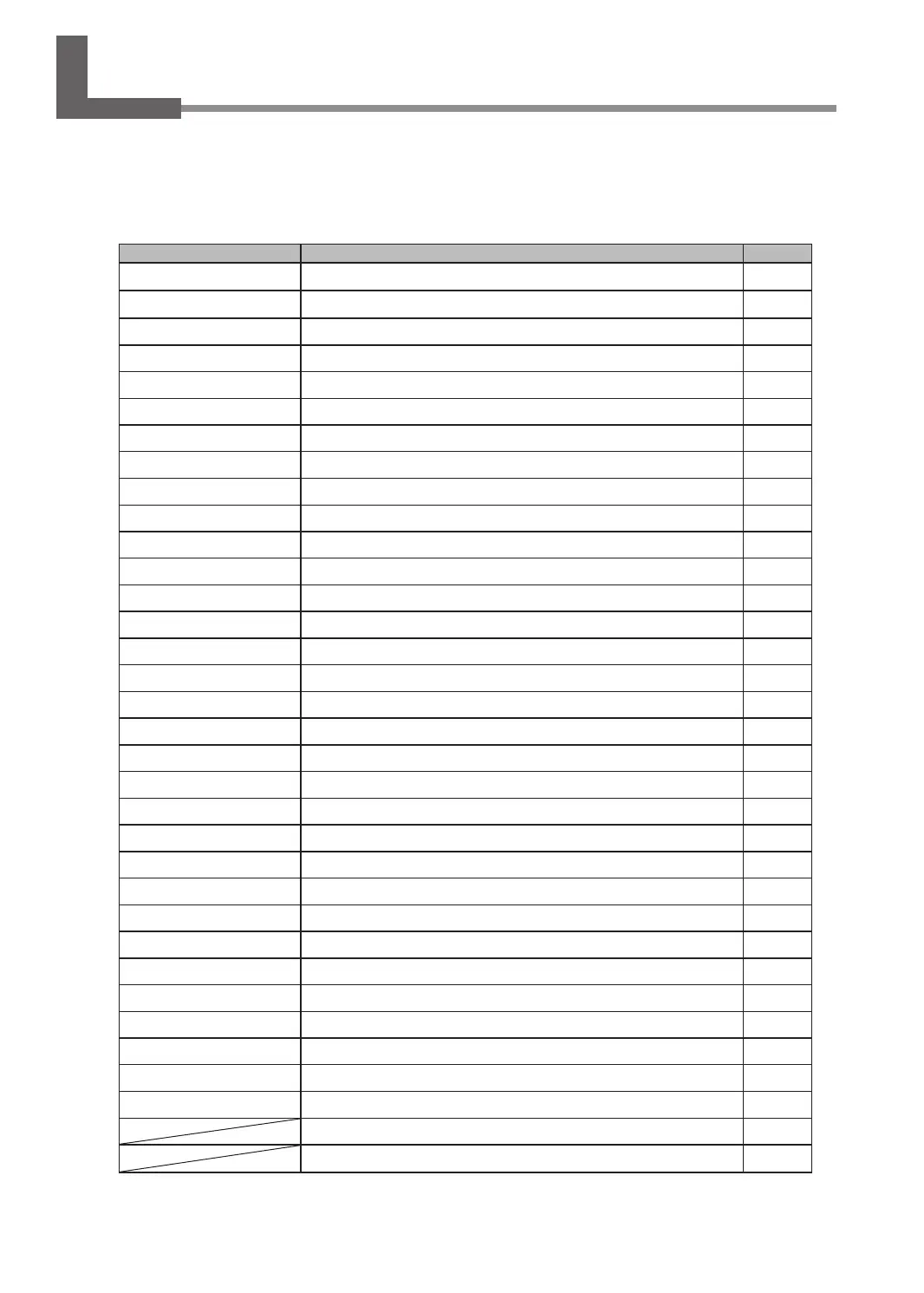

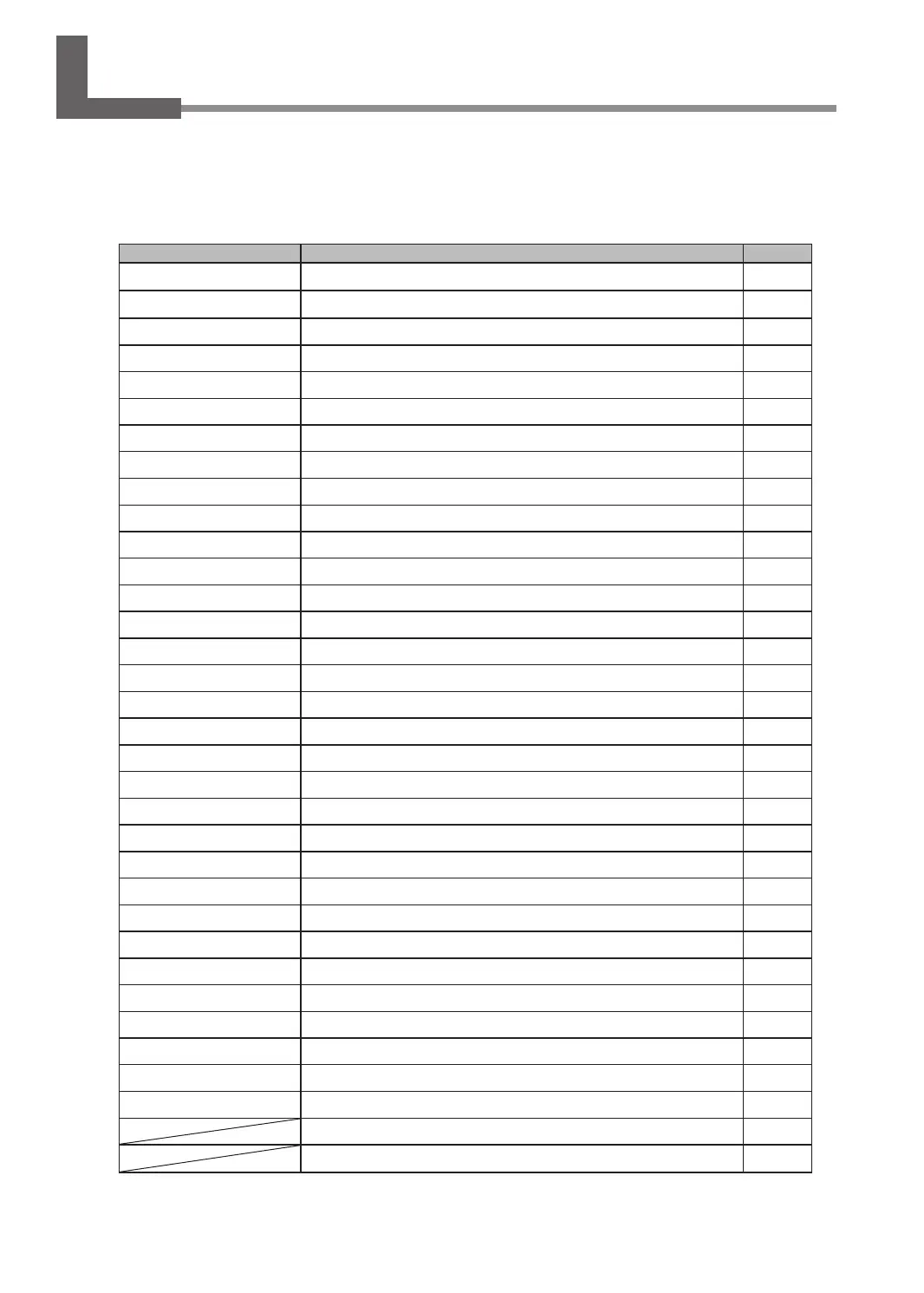

94

Chapter 4 FAQ

Responding to Error Messages

This section describes the error messages that may appear in VPanel and how to take action to remedy the

problem. If the action described here does not correct the problem or if an error message not described here

appears, contact your authorized DGSHAPE Corporation dealer. ("%" in these messages indicates information such

as axis "X," "Y," "Z," "A," "B," "L,"* or "T"** or a milling bur stocker number from 1 to 15.)

* The vertical movement axis of the lift ** The horizontal movement axis of the traverser

Error number Message Action

1000-**** The % limit switch was not found.

P.95

1006-02** The % axis position has been shifted.

P.95

1017-0000 The front cover was opened.

P.96

1017-0001 The front cover or the magazine cover was opened.

P.96

101C-0000 The milling bur sensor was not found.

P.97

101D-000* The % milling bur cannot be released.

P.97

101D-0010 The cleaning tool cannot be released.

P.98

101E-**** The % milling bur might be broken.

P.99

101F-**** The % milling bur chucking has slipped out.

P.100

1020/1021-**** The % milling bur is too long./The % milling bur is too short.

P.100

1022-000* The % milling bur was not found.

P.101

1022-0010 The cleaning tool was not found.

P.101

1023-0000 to 1028-0000 Milling data error.

P.102

1029-0000 The spindle experienced an overload.

P.103

102A-0000 The spindle experienced overcurrent.

P.103

102B-0000 The spindle motor temperature is too high.

P.104

102D-0000 The spindle can not be turned.

P.104

102E-0000 The spindle has collided with the rotary axis unit.

P.104

102E-0001 The changer has collided with the adapter.

P.105

1030-0000 The dust collector is not working.

P.105

103B-0000 The automatic correction is not yet nished.

P.106

103D-0000 Milling data error. The milling bur cannot reach the milling position.

P.106

1047-**** The machine's internal memory cannot be accessed.

P.107

1049-**** The adapter with ID number % cannot be released.

P.107

104A-**** The adapter with ID number % could not be grasped.

P.108

104B-**** The adapter with ID number % was not found.

P.108

104C-**** All stockers are full, so the adapter could not be returned.

P.109

104D-**** An adapter with the same ID was found.

P.109

104E-**** The % limit switch was not found.

P.109

104F-02** The % axis position has been shifted.

P.110

1050-**** The operation to read a barcode failed.

P.110

****-**** An unknown error occurred.

P.111

A machine that has the same ID has been connected.

P.111

The adapter to use during milling has not been set.

P.111

Loading...

Loading...