Correcting the Milling Machine

The accuracy of the milling machine may change if it is used for a long period of time or the surrounding

environment changes. Performing automatic correction will correct the ATC magazine and rotary axis positions.

Situations Requiring This Work

• When installing the machine

• When replacing the spindle unit

• When the milling position is misaligned

• When symptoms such as a level dierence or a hole in the Z direction occur in the milling results

Required Items

Detection pin Automatic correction jig Cloth for care

1.

Install the detection pin.

A

Clean off any milling waste around the clamp.

" P.59 "Cleaning after Milling Finishes"

B

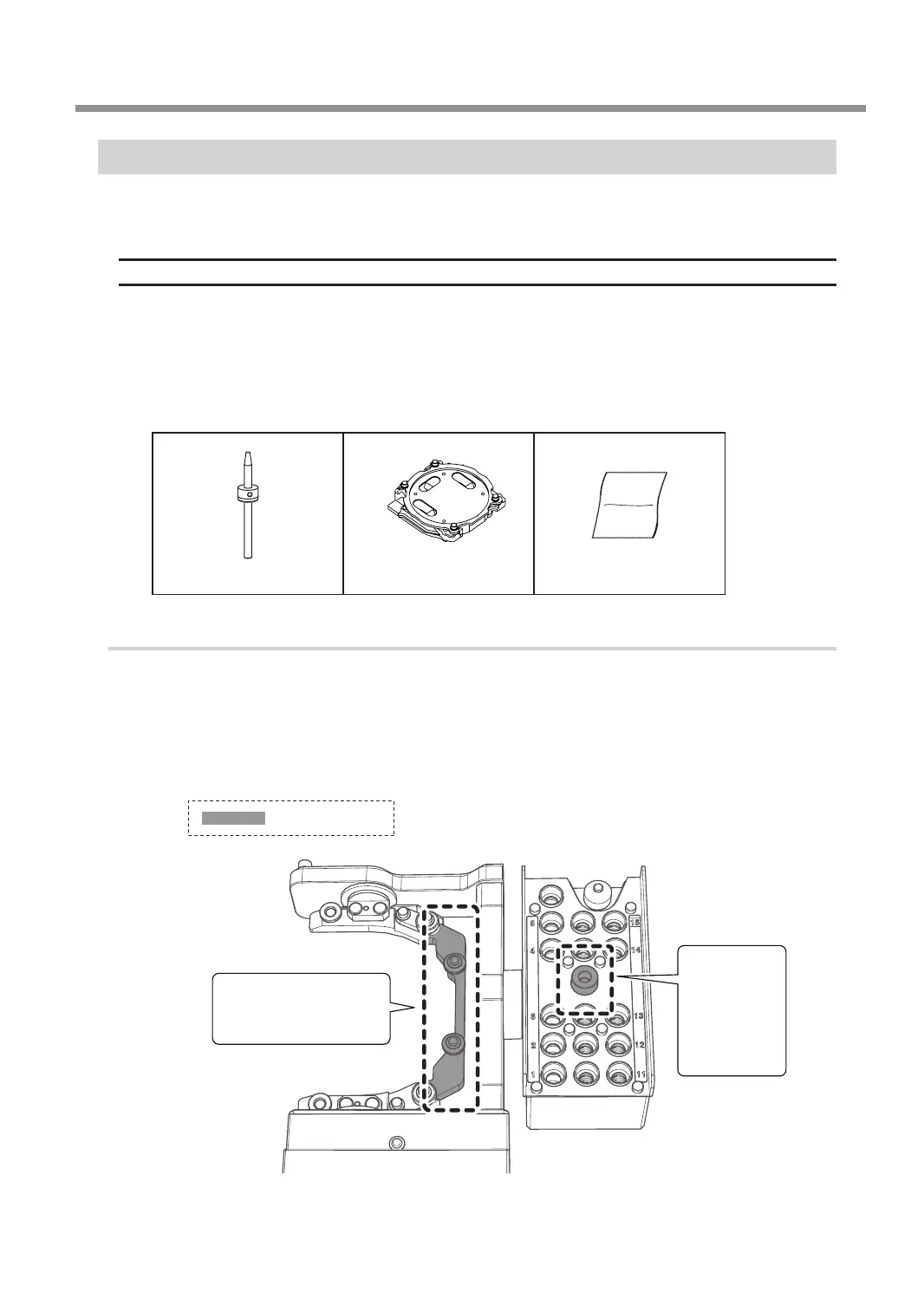

Use the included cloth for care to wipe clean locations 1 and 2 in the gure shown

below.

If any dirt is present in these locations, it may not be possible to perform the correction properly.

1

Also clean the back side.

2

Central

protrusion

on the ATC

magazine

Part to be wiped

Periodic Maintenance

65

Chapter 3 Maintenance

Loading...

Loading...