Lashing points and carrier systems

292

Technical data

! Observe the data on the maximum load-

bearing capacity of the individual lashing points.

During full-braking applications, for example,

forces can be involved that are much greater

than the weight force of the load.

Always use several lashing points in order

to distribute force absorption, and make

sure that the lashing points have an equal

load.

You will find further information on the

lashing eyes in the "Controls in detail" sec-

tion (

e page 137).

Lashing eyes

The maximum tensile load of the lashing

eyes is:

Load rails

The maximum tensile load of the lashing

points in the load compartment is:

The specified values only apply to loads on

the load compartment floor if:

O the load is secured to 2 lashing points

on the rail and

O the distance to the next lashing point

used on the same rail is about 3 ft

(1 m).

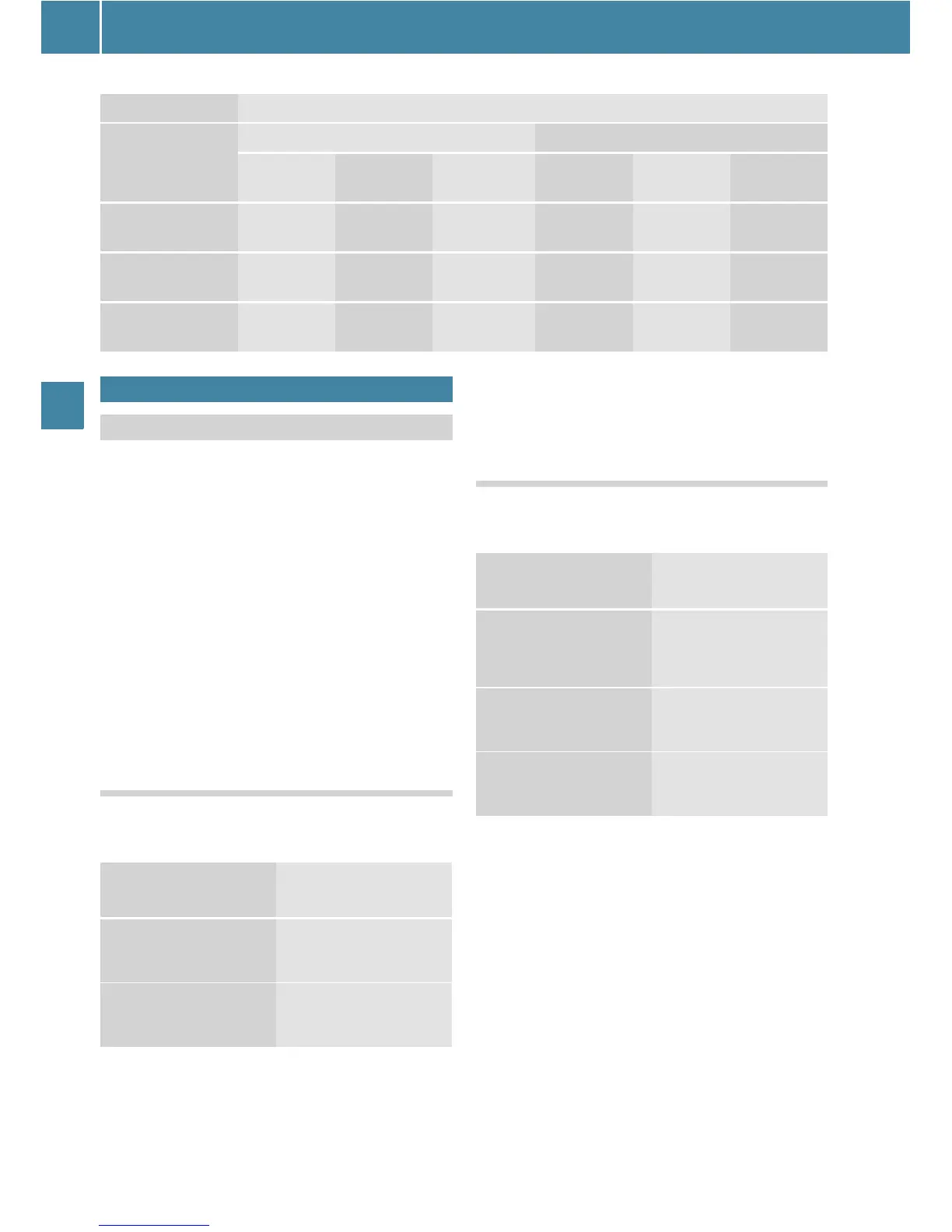

Tire Permissible axle loads (see certification label)

Front axle Rear axle

3970 lbs

(1801 kg)

4080 lbs

(1851 kg)

4410 lbs

(2000 kg)

5360 lbs

(2431 kg)

7060 lbs

(3202 kg)

7720 lbs

(3502 kg)

LT 215/85 R 16

115/112 N

—

55 psi

(3.8 bar)

61 psi

(4.2 bar)

—

55 psi

(3.8 bar)

61 psi

(4.2 bar)

LT 215/85 R 16

115/112 Q

—

55 psi

(3.8 bar)

61 psi

(4.2 bar)

—

55 psi

(3.8 bar)

61 psi

(4.2 bar)

LT 245/75 R 16

120/116 N

47 psi

(3.2 bar)

— —

70 psi

(4.8 bar)

— —

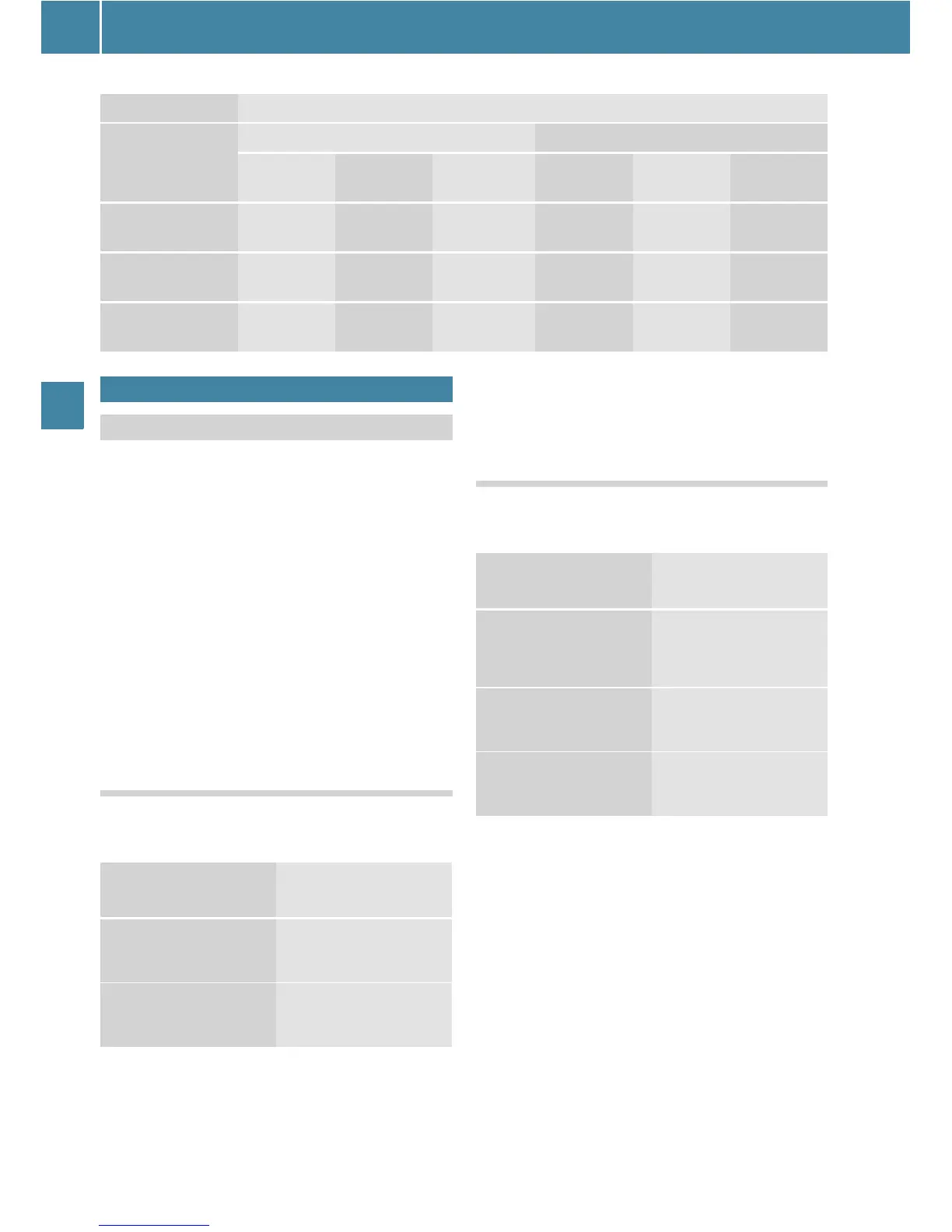

Lashing points and carrier systems

Lashing points

Lashing eyes Permissible nom-

inal tensile force

Crewbus 786.5 lbf

(3500 N)

Panel van 1124.0 lbf

(5000 N)

Lashing point Permissible nom-

inal tensile force

Load rails in the

load compartment

floor

1124.0 lbf

(5000 N)

Lower load rail on

the sidewall

562.0 lbf

(2500 N)

Upper load rail on

the sidewall

337.0 lbf

(1500 N)

Loading...

Loading...