5-137

d32, d33 Torque Control (Speed limit 1 and Speed limit 2) (Refer to H18.)

d41 Application-Defined Control

The constant peripheral speed control is available as an application, which suppresses an increase in peripheral speed

(line speed) resulting from the increasing radius of the take-up roll in a winder system.

In a winder system (e.g., roving frames, wiredrawing machines), if the inverter continues to run the motor at a constant

speed, the take-up roll gets bigger with materials (roving, wire, etc.) and its radius increases so that the winding speed

of the take-up roll increases.

Under the application-defined control, to keep the peripheral speed (winding speed) constant, the inverter detects the

winding speed using an encoder and controls the motor rotation according to the encoder feedback.

Application-Defined Control (d41)

d41 specifies whether to enable or disable the constant peripheral speed control.

Data for d41 Function

0

Disable (Ordinary control)

1

Enable (Constant peripheral speed control)

Note: This control is valid only when "V/f control with speed sensor" or "Dynamic torque vector

control with speed sensor" is selected with F42, A14, b14, or r14 (data = 3 or 4).

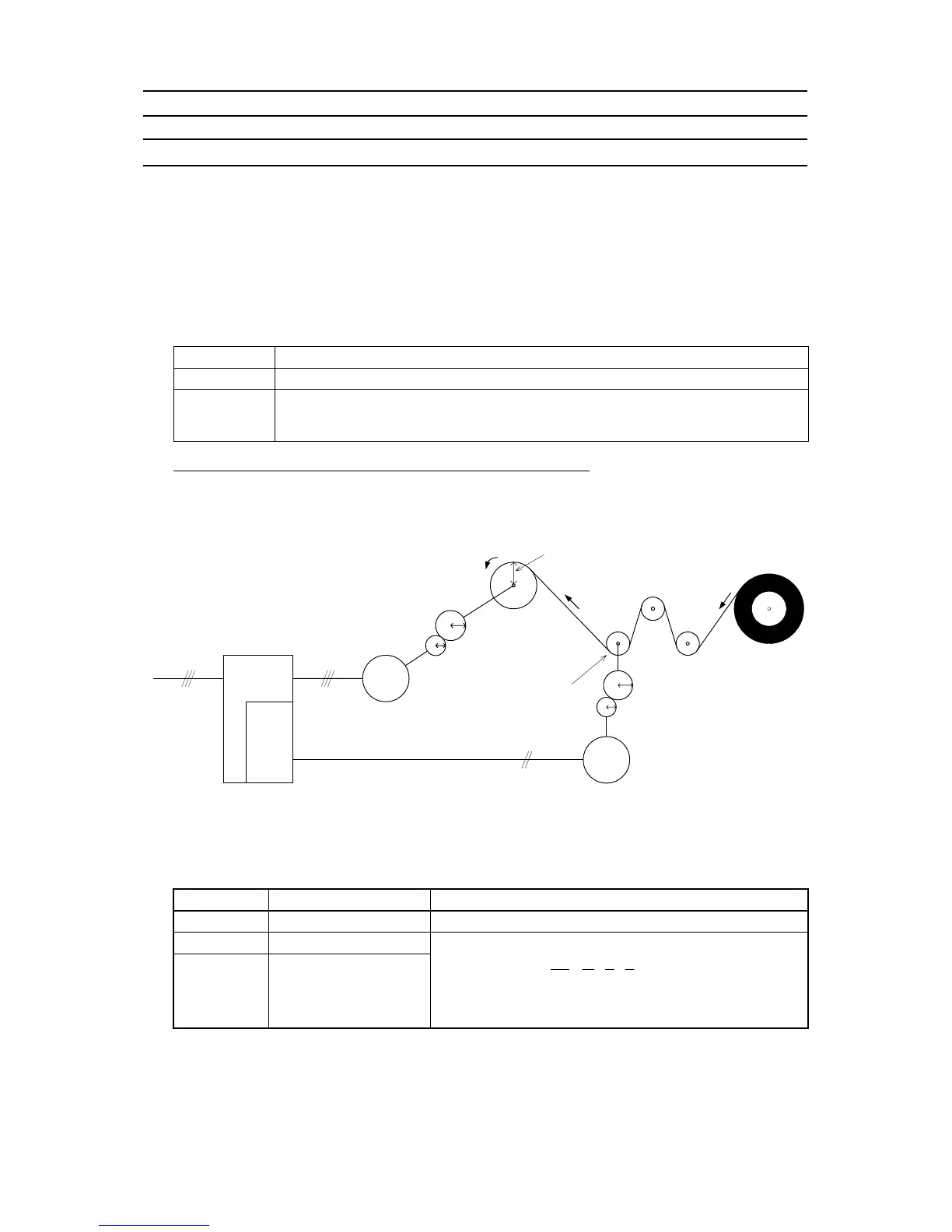

Mechanical configuration of a winder system and function code settings

Shown below is a typical mechanical configuration of a winder system for which it is necessary to configure the

function codes as listed below.

Inverter

Encoder

I/F card

U, V, W

R, S, T

Reduction ratio a:b

(When the motor shaft

rotates “b” times, the take-

up roll shaft rotates “a”

times.)

Speed v

in winding direction

Drum

Winder

(The radius of the take-up roll increases

as the roll rotates.)

Speed v

A/B phase or B phase

Motor

Encoder

b

a

c

d

Reduction ratio c: d

(When the speed detector shaft

rotates “d” times, the encoder

shaft rotates “c” times.)

Radius of take-up roll (r1)

Speed detector

radius r

2

- Speed reduction ratio between motor shaft and take-up roll shaft a : b

- Speed reduction ratio between speed detector shaft and encoder shaft c : d

- Radius of take-up roll before winding r

1

(m)

- Radius of speed detector r

2

(m)

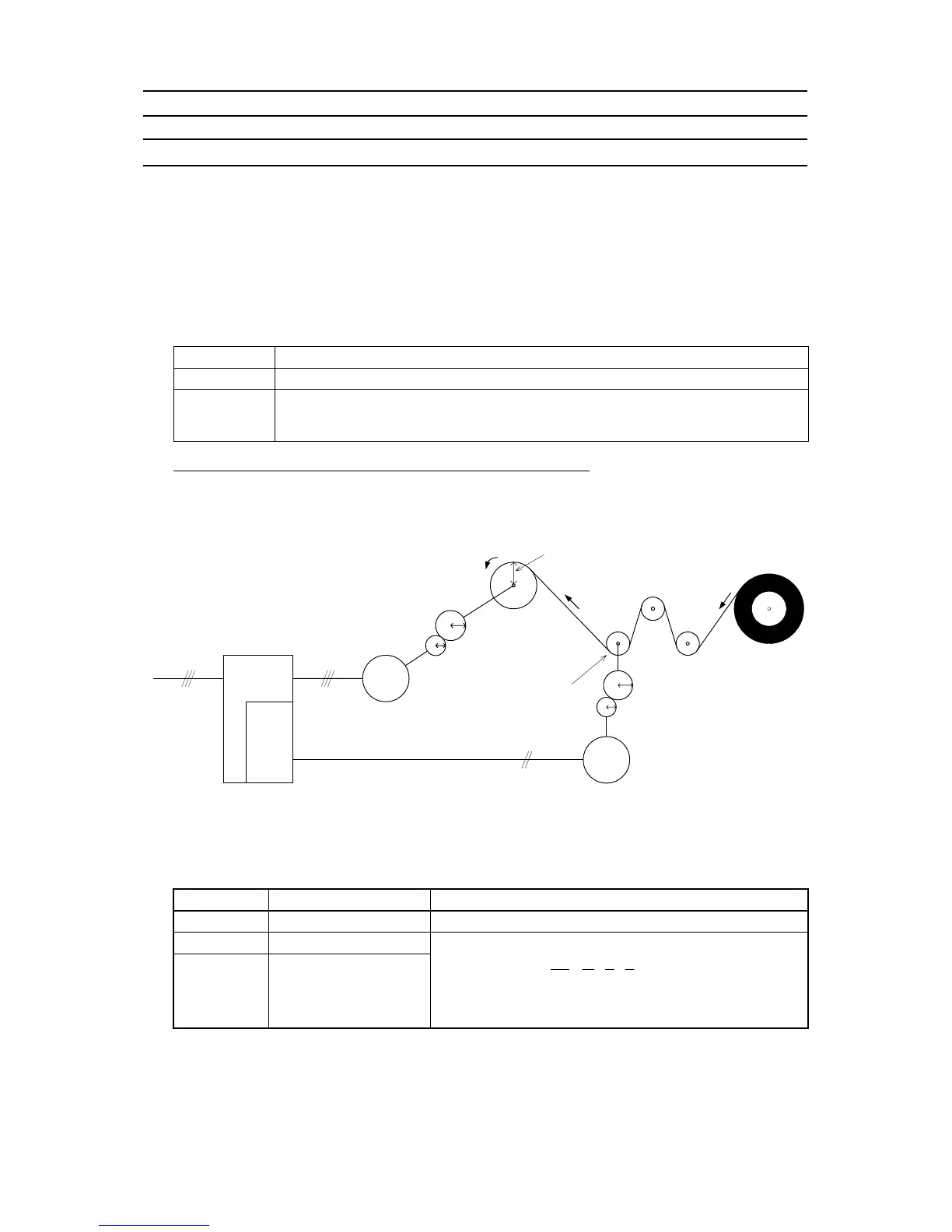

Setting the Reduction Ratio

Function code Name Settings

d15

Encoder pulse resolution

Encoder pulse resolution (P/R) to be set in hexadecimal

d16

Pulse count factor 1

d17 Pulse count factor 2

Speed reduction ratio of the whole machinery (load)

d17/d16

c

d

a

b

r

r

K

K

1

2

1

2

=××=

d16: Denominator factor for the speed reduction ratio (K1 = r1 × a × c)

d17: Numerator factor for the speed reduction ratio (K2 = r2 × b × d)

Loading...

Loading...