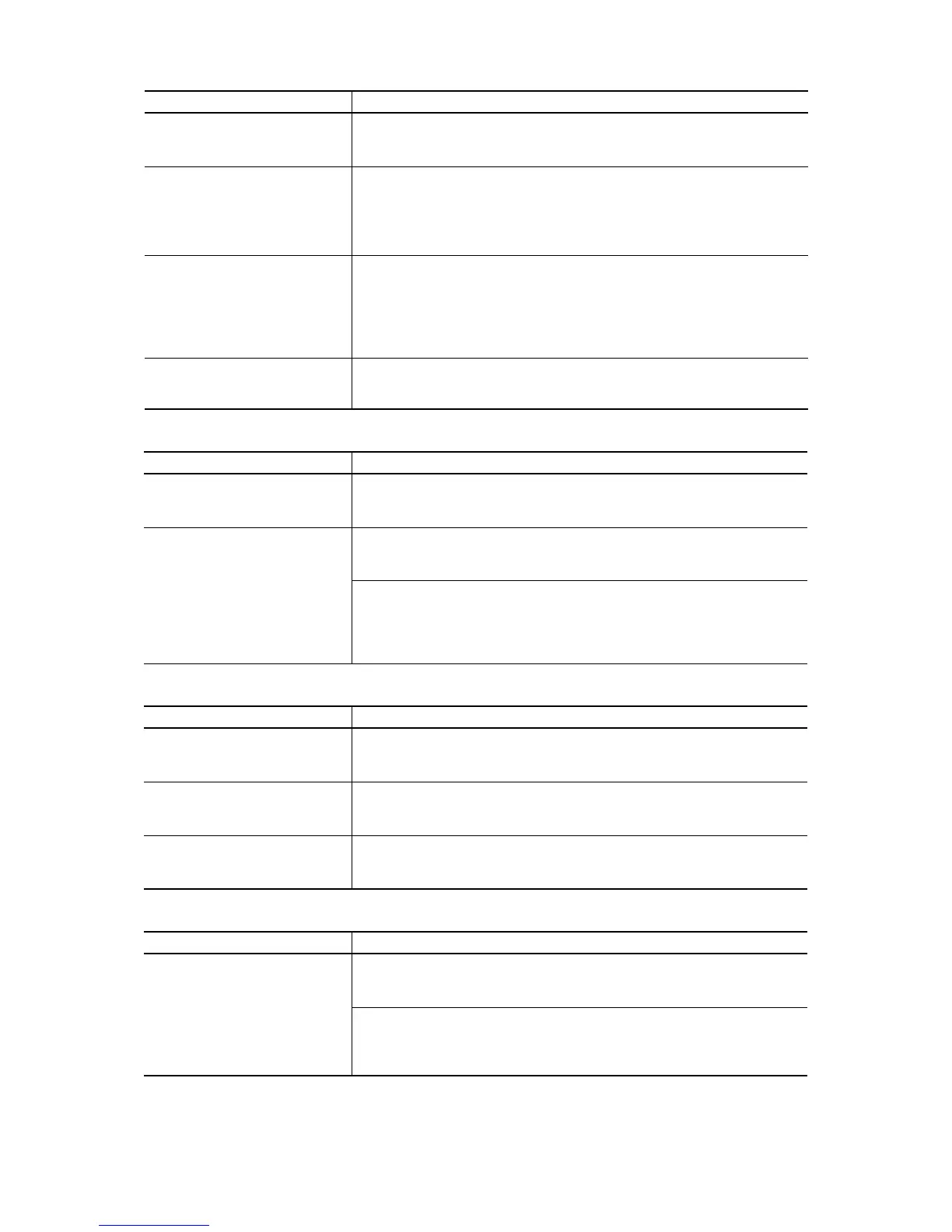

6-8

Possible Causes What to Check and Suggested Measures

(5) Torque generated by the motor

was insufficient.

Check that the motor starts running if the value of the torque boost (F09*) is

increased.

Î Increase the value of the torque boost (F09*).

(6) An external potentiometer is

used for frequency setting.

Check that there is no noise in the control signal wires from external sources.

Î Isolate the control signal wires from the main circuit wires as far as possible.

Î Use shielded or twisted wires for control signals.

Î Connect a capacitor to the output terminal of the external frequency command

potentiometer or set a ferrite core on the signal wire. (Refer to Chapter 2.)

(7) The output frequency is limited

by the torque limiter.

Check whether data of torque limiter related function codes (F40, F41, E16 and

E17) is correctly configured and the TL2/TL1 terminal command ("Select torque

limiter level 2/1") is correct.

Î Correct the data of F40, F41, E16 and E17 or reset them to the factory defaults.

Î Set the TL2/TL1 correctly.

Î Increase the acceleration/deceleration time (F07, F08, E10 through E15).

(8) The specified acceleration or

deceleration time was

incorrect.

Check the terminal commands RT1 and RT2 for acceleration/deceleration times.

Î Correct the RT1 and RT2 settings.

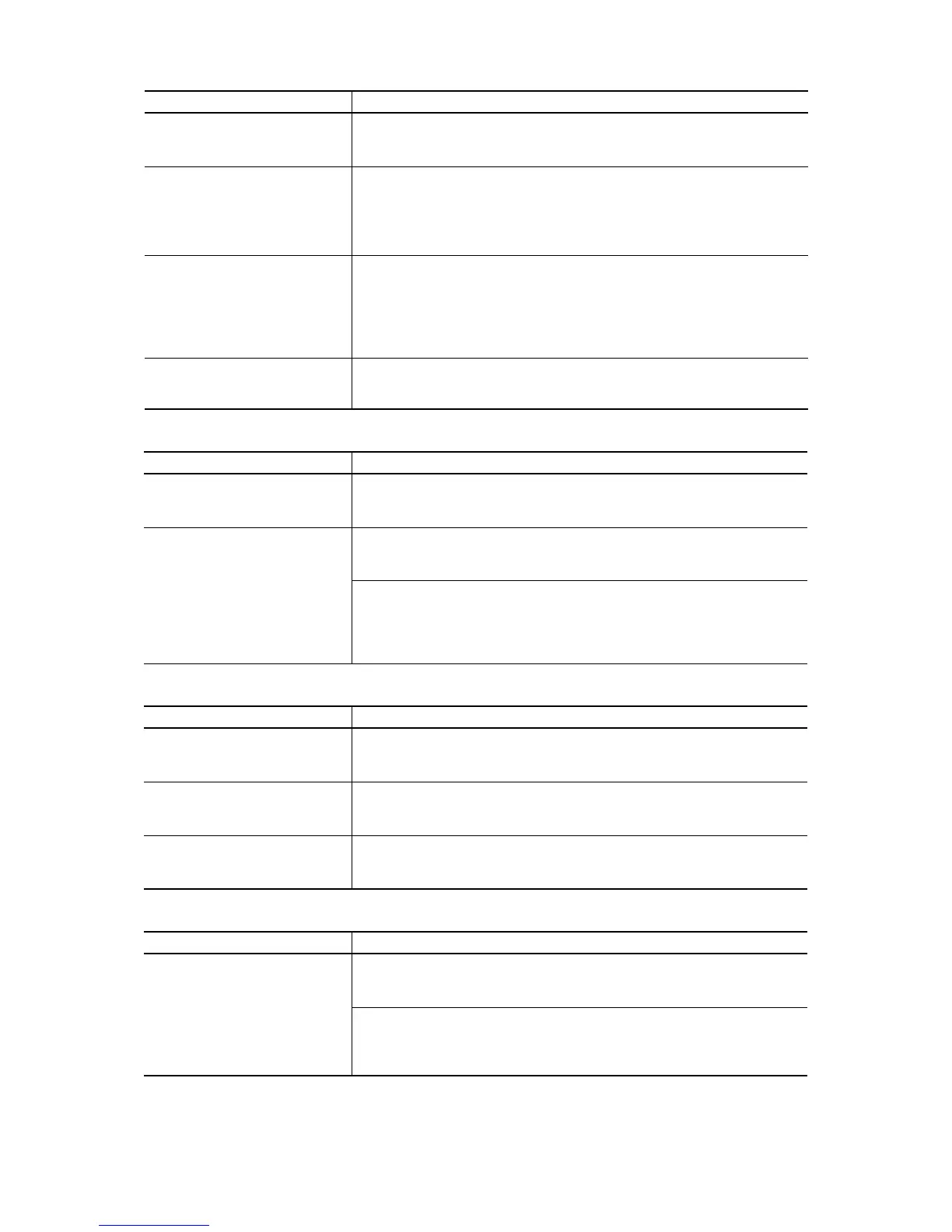

[ 7 ] The motor does not restart even after the power recovers from a momentary power failure.

Possible Causes What to Check and Suggested Measures

(1) The data of function code F14

is either "0," "1," or "2."

Check if an undervoltage trip (

lu

) occurs.

Î Change the data of function code F14 (Restart mode after momentary power

failure (Mode selection)) to "3," "4," or "5."

Check the input signal with Menu #4 "I/O Checking" using the keypad.

Î Check the power recovery sequence with an external circuit. If necessary,

consider the use of a relay that can keep the run command ON.

(2) The run command remains

OFF even after the power has

been restored.

In 3-wire operation, the power to the control printed circuit board (control PCB) has

been shut down once because of a long momentary power failure time, or the

"Enable 3-wire operation" signal HOLD has been turned OFF once.

Î Change the design or the setting so that a run command can be issued again

within 2 seconds after the power has been restored.

[ 8 ] The motor abnormally heats up.

Possible Causes What to Check and Suggested Measures

(1) Excessive torque boost

specified.

Check whether decreasing the torque boost (F09*) decreases the output current but

does not stall the motor.

Î If no stall occurs, decrease the torque boost (F09*).

(2) Continuous running in

extremely slow speed.

Check the running speed of the inverter.

Î Change the speed setting or replace the motor with a motor exclusively designed

for inverters.

(3) Overload. Measure the inverter output current.

Î Reduce the load (For fans or pumps, decrease the frequency limiter value

(F15).) (In winter, the load tends to increase.)

[ 9 ] The motor does not run as expected.

Possible Causes What to Check and Suggested Measures

Check that function codes are correctly configured and no unnecessary

configuration has been done.

Î Configure all the function codes correctly.

(1) Incorrect setting of function

code data.

Make a note of function code data currently configured and then initialize all

function code data using H03.

Î After the above process, reconfigure function codes one by one, checking the

running status of the motor.

Loading...

Loading...