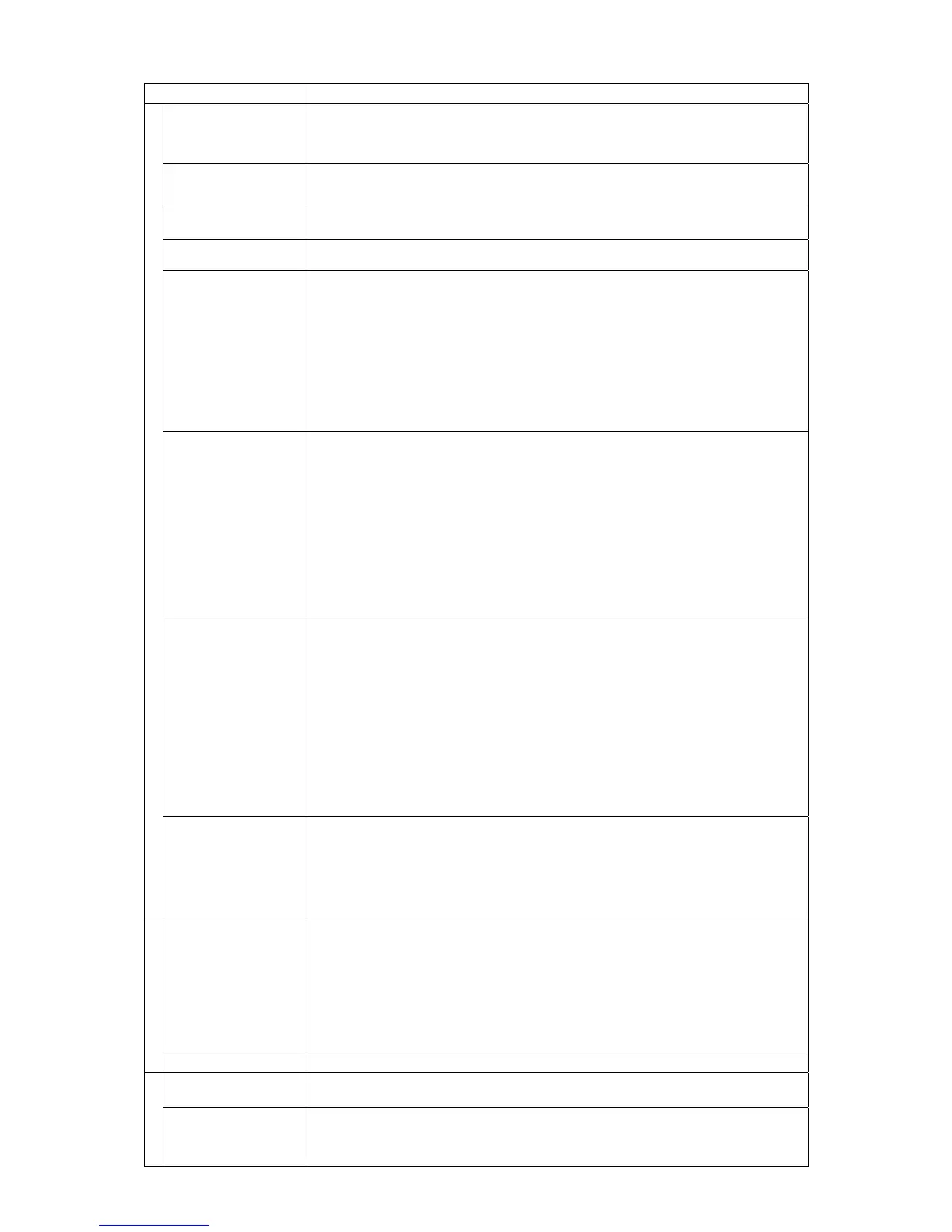

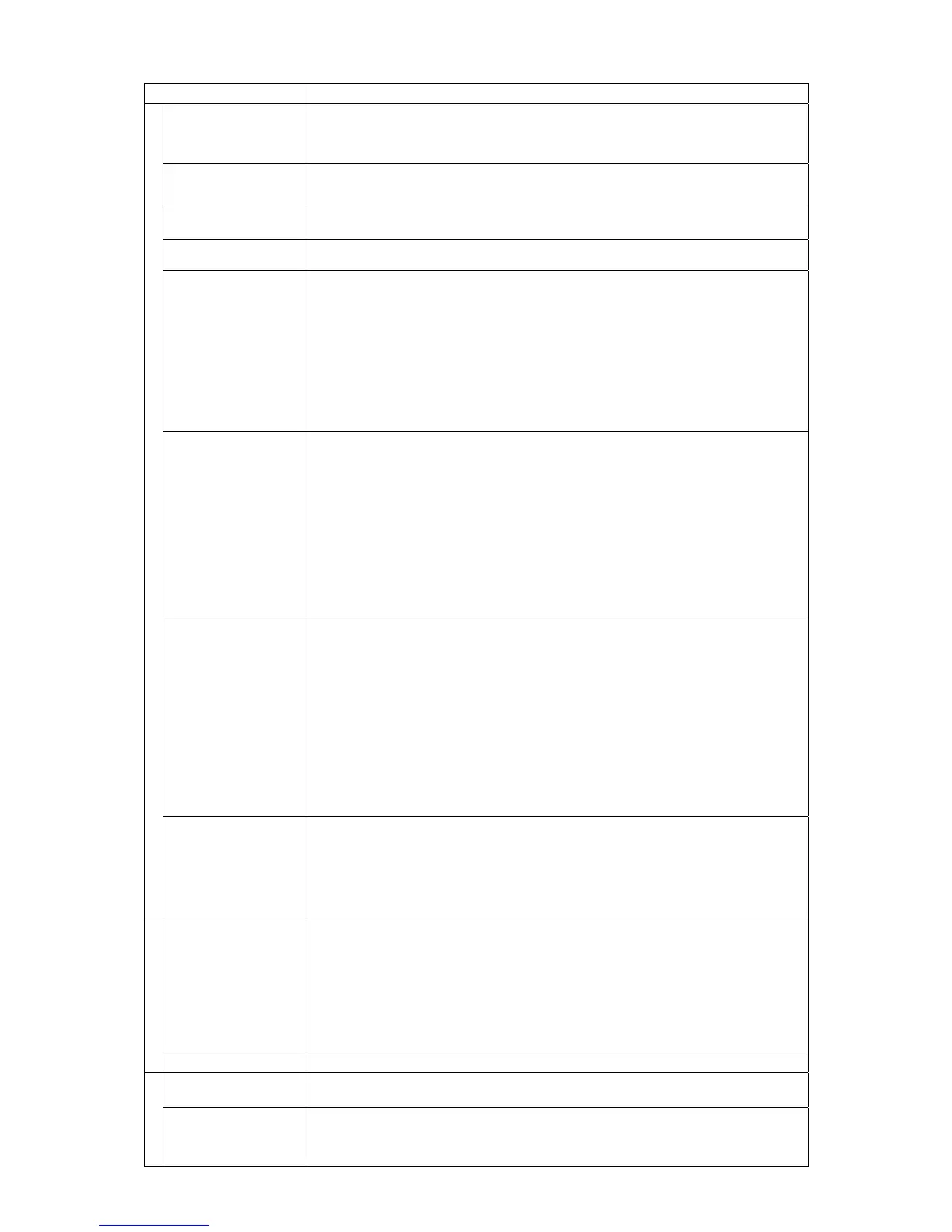

8-10

Item Explanation

Stop control

• Running continued at the stop frequency, coast-to-stop, or force to stop.

• DC braking: Braking starting frequency (up to 60 Hz), time (up to 30.0 s), and operation level

(up to 100%)

• Zero speed control (under vector control with speed sensor.)

Auto-restart after

momentary power failure

• Trip immediately, trip after recovery from power failure, trip after deceleration to stop

• Continue to run, restart at the frequency at which the power failure occurred, restart at the

starting frequency, restart after searching for idling motor speed

Hardware current limiter

• Current limiter operation level (20 to 200%)

• Overcurrent limiting by hardware (This can be canceled.)

Torque limiter

• Torque limit value (±300%)

• Torque limiter 1/2, torque limiter enabled/disabled, analog torque limit value

Control functions

• Analog input adjustment (gain/offset/filter time constant), frequency limiter (high and low),

bias frequency, jump frequency, jogging operation, pre-excitation, switch to commercial power,

commercial power switching sequence, cooling fan ON/OFF control, select motor 2 to 4,

protect motor from dew condensation, universal DI, universal DO, universal AO, rotational

direction limitation

• Overload prevention control, auto search, slip compensation, automatic deceleration

(anti-regenerative control), droop control, PID process control, PID dancer control,

Deceleration characteristics (improving braking capability), auto energy saving function

• Auto-tuning (offline)

• Life early warning, cumulative inverter run time, cumulative motor run time

• Light alarm, retry, command loss detection

Digital input

Run forward command, run reverse command, select multi-frequency, select ACC/DEC time,

enable 3-wire operation, coast to a stop, reset alarm, enable external alarm trip, ready for jogging,

select frequency command 2/1, select motor 1 to 4, enable DC braking, select torque limiter level,

switch to commercial power, UP (increase output frequency), DOWN (decrease output

frequency), enable data change with keypad, cancel PID control, switch normal/inverse operation,

interlock, cancel torque control, enable communications link via RS-485 or fieldbus (option),

universal DI, enable auto search for idling motor speed at starting, force to stop, pre-excitation,

reset PID integral and differential components, hold PID integral component, select local (keypad)

operation, protect the motor from dew condensation, enable internal sequence to commercial lines,

pulse train input, pulse train sign, cancel constant peripheral speed control, hold the constant

peripheral speed control frequency in the memory, switch to commercial power operation, select

droop control, servo-lock command, cancel PG alarm, cancel customizable logic, clear all

customizable logic timers

Transistor output

Inverter running, frequency arrival signal 1/3, frequency detected (3 points), undervoltage

detected (inverter stopped), torque polarity detected, inverter output limiting, auto-restarting after

momentary power failure, motor overload early warning, keypad operation, inverter ready to run,

switch motor power between commercial line and inverter output (inverter

input/output/commercial power), select the AX terminal function (primary side MC), inverter

output limiting with delay, cooling fan in operation, auto-resetting, universal DO, heat sink

overheat early warning, service lifetime alarm, reference loss detected, inverter output on,

overload prevention control, current detected (3 points), low level current detected, PID alarm,

under PID control, PID control stopped due to slow flowrate, low output torque detected, torque

detected (2 points), switched to motor 1 to 4, run forward signal, run reverse signal, inverter in

remote operation, PTC status detection enabled, brake signal, analog frequency reference loss on

the terminal [C1], inverter keeping speed output, speed arrived, PG error detected, maintenance

timer, light alarm, alarm relay contact output (for any fault), braking resistor broken, positioning

completion signal, enable circuit failure detected, customizable logic output signal

Control

Analog output

Terminals [FM1] and [FM2]:

Output a selected signal with analog DC voltage (0 to +10 V) or analog DC current (4 to 20 mA)

Selectable output signals:

Output frequency (before slip compensation, after slip compensation), output current, output

voltage, output torque, load factor, input power, PID feedback amount, speed (PG feedback value),

DC link bus voltage, universal AO, motor output, calibration, PID command (SV), PID output

(MV)

Running/stopping

Speed monitor (reference frequency (Hz), output frequency, motor speed, load shaft speed, line

speed, speed in %)

Output current, output voltage, torque calculation value, input power, PID command value, PID

feedback amount, PID output, load factor, motor output, torque current, flux command, analog

signal input monitor, input watt-hour

Life early warning, cumulative inverter run time, cumulative motor run time, input watt-hour,

number of startups

I/O checking, energy-saving monitor (input power, input power x coefficient (charges for input

power))

Indication

Trip mode Trip history: Saves and displays the last 4 trip factors and their detailed description.

Communications

RS-485 COM port 1 (for keypad connection), RS-485 COM port 2 (on terminal block), and USB

port (on the keypad face)

Other features

Protection against

momentary power failure

Upon detection of a momentary power failure lasting more than 15 ms, this function stops the

inverter output. If restart after momentary power failure is selected, this function invokes a restart

process if power is restored within a predetermined period (allowable momentary power failure

time).

Loading...

Loading...