2-21

Table 2.7 Symbols, Names and Functions of the Control Circuit Terminals (Continued)

Classifi-

cation

Symbol Name Functions

[Y1]

Transistor

output 1

[Y2]

Transistor

output 2

(1) Various signals such as inverter running, speed/freq. arrival and overload early

warning can be assigned to any terminals, [Y1] to [Y4] by setting function code E20

to E24. Refer to Chapter 5, Section 5.2 "Details of Function Codes" for details.

(2) Switches the logic value (1/0) for ON/OFF of the terminals between [Y1] to [Y4],

and [CMY]. If the logic value for ON between [Y1] to [Y4] and [CMY] is 1 in the

normal logic system, for example, OFF is 1 in the negative logic system and vice

versa.

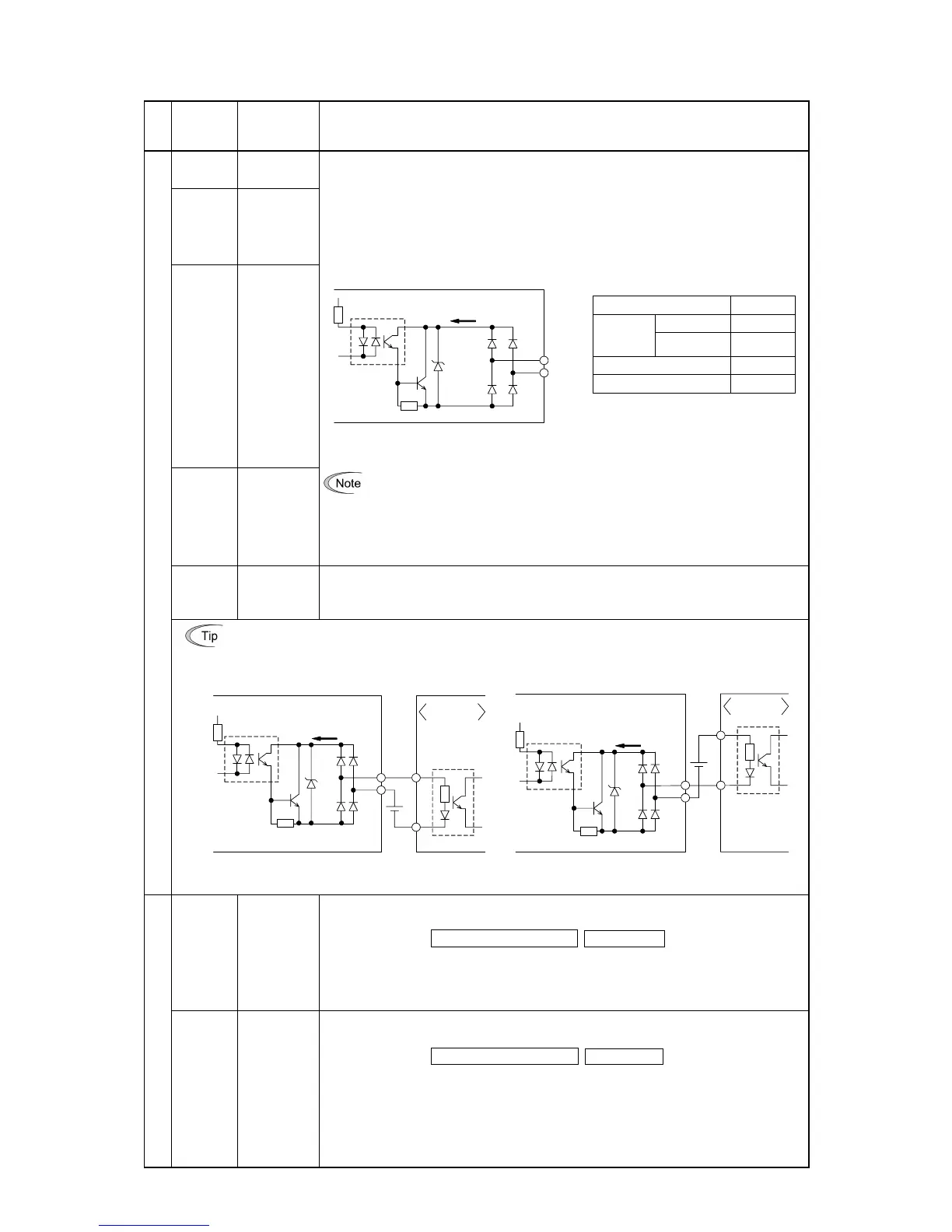

(Transistor output circuit specification)

Photocoupler

<Control circuit>

[Y1]

to

[Y4]

[CMY]

31 to 35 V

Voltage

Current

Figure 2.16 Transistor Output Circuit

Item Max.

ON level 2 V

Operation

voltage

OFF level 27 V

Maximum current at ON 50 mA

Leakage current at OFF 0.1 mA

[Y3]

Transistor

output 3

Figure 2.17 shows examples of connection between the control circuit and a PLC.

[Y4]

Transistor

output 4

- When a transistor output drives a control relay, connect a surge-absorbing diode

across relay’s coil terminals.

- When any equipment or device connected to the transistor output needs to be

supplied with DC power, feed the power (+24 VDC: allowable range: +22 to

+27 VDC, 100 mA max.) through the [PLC] terminal. Short-circuit between the

terminals [CMY] and [CM] in this case.

[CMY]

Transistor

output

common

Common terminal for transistor output signals

This terminal is electrically isolated from terminals [CM] and [11]s.

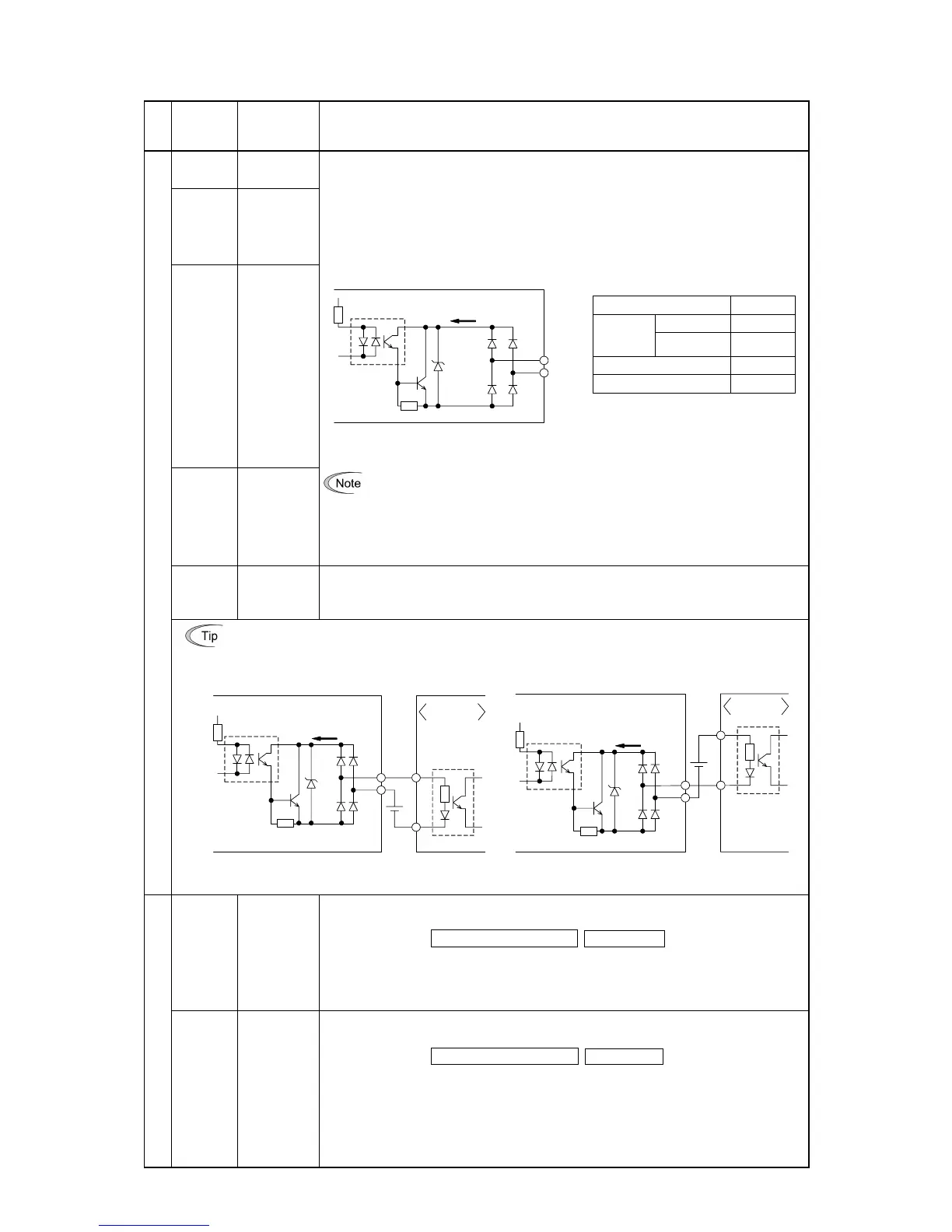

Connecting programmable logic controller (PLC) to terminal [Y1], [Y2], [Y3] or [Y4]

Figure 2.17 shows two examples of circuit connection between the transistor output of the inverter’s

control circuit and a PLC. In example (a), the input circuit of the PLC serves as a SINK for the control

circuit output, whereas in example (b), it serves as a SOURCE for the output.

C0

+24 VDC

Programmable

logic controller

SINK input

Photocoupler

<Control circuit>

[Y1]

to

[Y4]

[CMY]

31 to

35 V

Current

C0

Programmable

logic controller

SOURCE input

+24 VDC

Photocoupler

<Control circuit>

[Y1]

to

[Y4]

[CMY]

31 to

35 V

Current

(a) PLC serving as SINK (b) PLC serving as SOURCE

Transistor output

Figure 2.17 Connecting PLC to Control Circuit

[Y5A/C]

General

purpose relay

output

(1) A general-purpose relay contact output usable as well as the function of the transistor

output terminal [Y1], [Y2], [Y3] or [Y4].

Contact rating: 250 VAC 0.3 A, cos φ = 0.3, 48 VDC, 0.5 A

(2) Switching of the normal/negative logic output is applicable to the following two

contact output modes: "Active ON" (Terminals [Y5A] and [Y5C] are closed

(excited) if the signal is active.) and "Active OFF" (Terminals [Y5A] and [Y5C] are

opened (non-excited) if the signal is active while they are normally closed.).

Relay output

[30A/B/C]

Alarm relay

output

(for any

error)

(1) Outputs a contact signal (SPDT) when a protective function has been activated to

stop the motor.

Contact rating: 250 VAC, 0.3A, cos φ = 0.3, 48 VDC, 0.5A

(2) Any one of output signals assigned to terminals [Y1] to [Y4] can also be assigned to

this relay contact to use it for signal output.

(3) Switching of the normal/negative logic output is applicable to the following two

contact output modes: "Active ON" (Terminals [30A] and [30C] are closed (excited)

if the signal is active.) and "Active OFF" (Terminals [30A] and [30C] are opened

(non-excited) if the signal is active while they are normally closed.).

Loading...

Loading...