Revision 1 65 9/10/2019

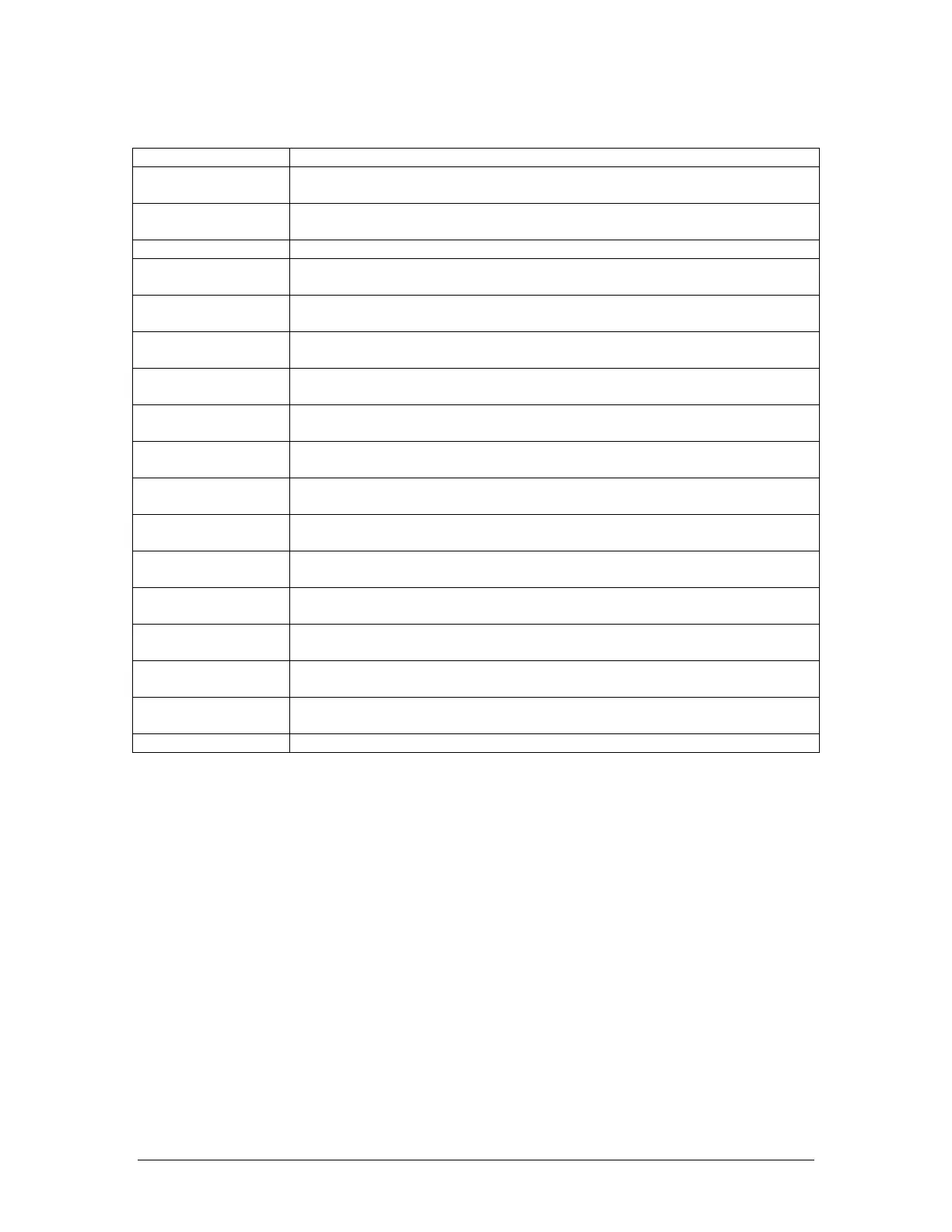

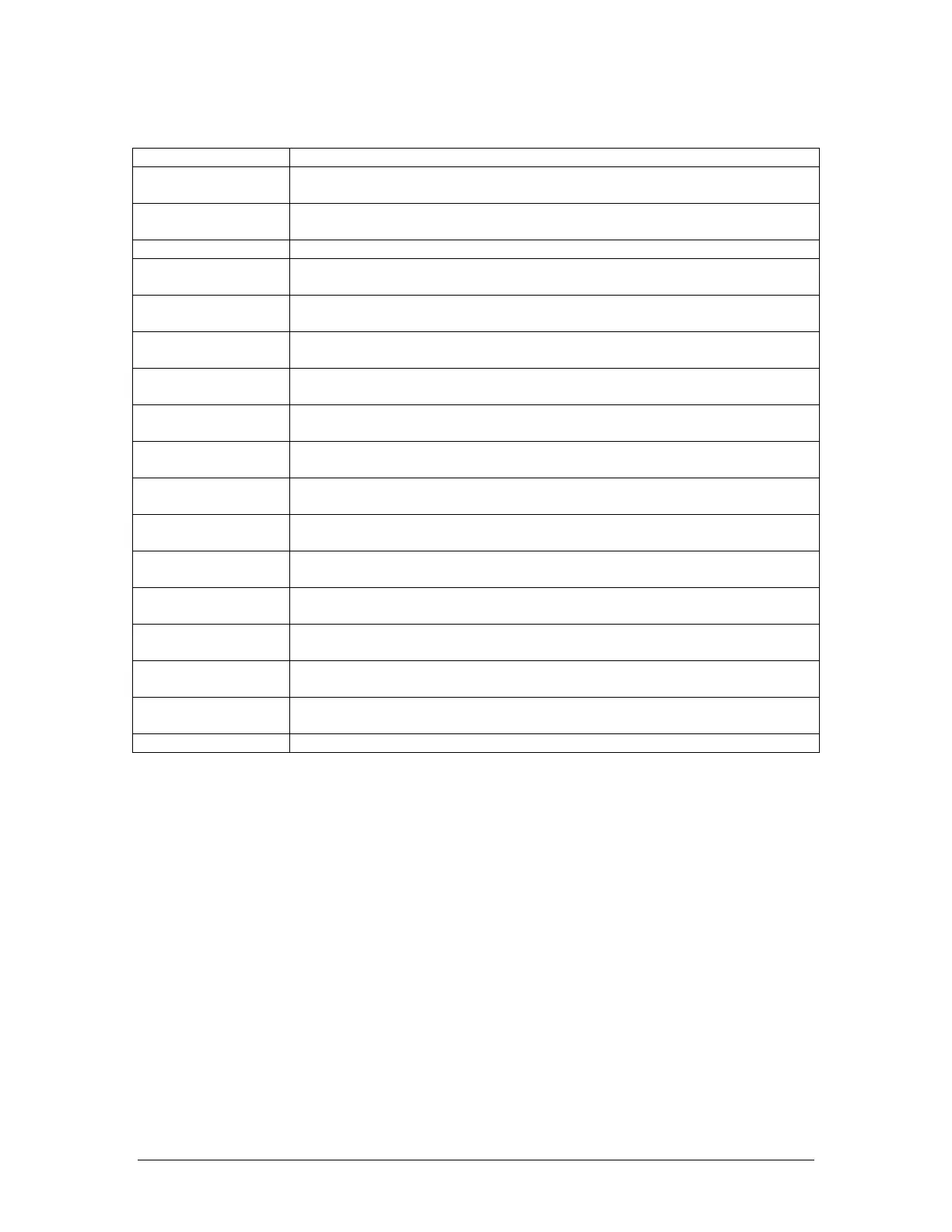

Table 5-4: Function of Each Tab

Allows the user to see the current status of the analyzer, including

concentration readings and input and output status.

Provides the current status of the analog outputs, relays, solenoids,

analog inputs, discrete inputs, and what voltage input source is in use.

Allows the operator to view all enabled system alarms.

Allows the operator to access the numerous archives that store live data,

hourly and daily averages, as well as other user configurable archives.

Allows the operator to access the Event Log, which keeps track of all the

configuration changes and events that the analyzer has experienced.

Allows the operator to change settings that affect the global operation of

the analyzer, such as stream purge times.

Allows the operator to change settings specific to each stream; normal,

zero, reference, and calibration.

Allows the operator to configure the four discrete (Dry) inputs of the

analyzer.

Allows the operator to configure the four discrete (Wet) inputs of the

analyzer.

Allows the operator to configure the behaviour of the relays, solenoids and

analog outputs.

Allows the operator to configure the analyzer gas run event sequences in

either, automatic or manual or both.

Allows the operator to view the settings of the analyzer’s communications

ports - RS-232, RS-485, and USB.

Allows the operator to configure Modbus lists, including the type of

Modbus list and the data points that are outputted to Modbus.

Allows the operator to configure the 4 analog inputs including the live

pressure and temperature readings and related alarm set points.

Allows the operator to schedule conditional gas run operational requests

on an hourly, daily or weekly basis.

Allows the operator and service personnel to have greater control over the

electronics board, for testing analog outputs, relays, and solenoids.

Reserved for factory and service personnel

5.2.4 Status Bar

The Status bar, which is located at the bottom of the window, presents the update status, the

present time/date and traffic lights to indicate the status of communication between the

analyzer and the computer.

Loading...

Loading...