GE Healthcare Senographe DS

Revision 1 Service Information and Procedures Class A 2385072-16-8EN

Job Card TSG A015 - Lift Movement Troubleshooting

Page no. 1057 Chapter 9

JC-TSG-A-015.fm

3-5 Bearing and Lift Checks

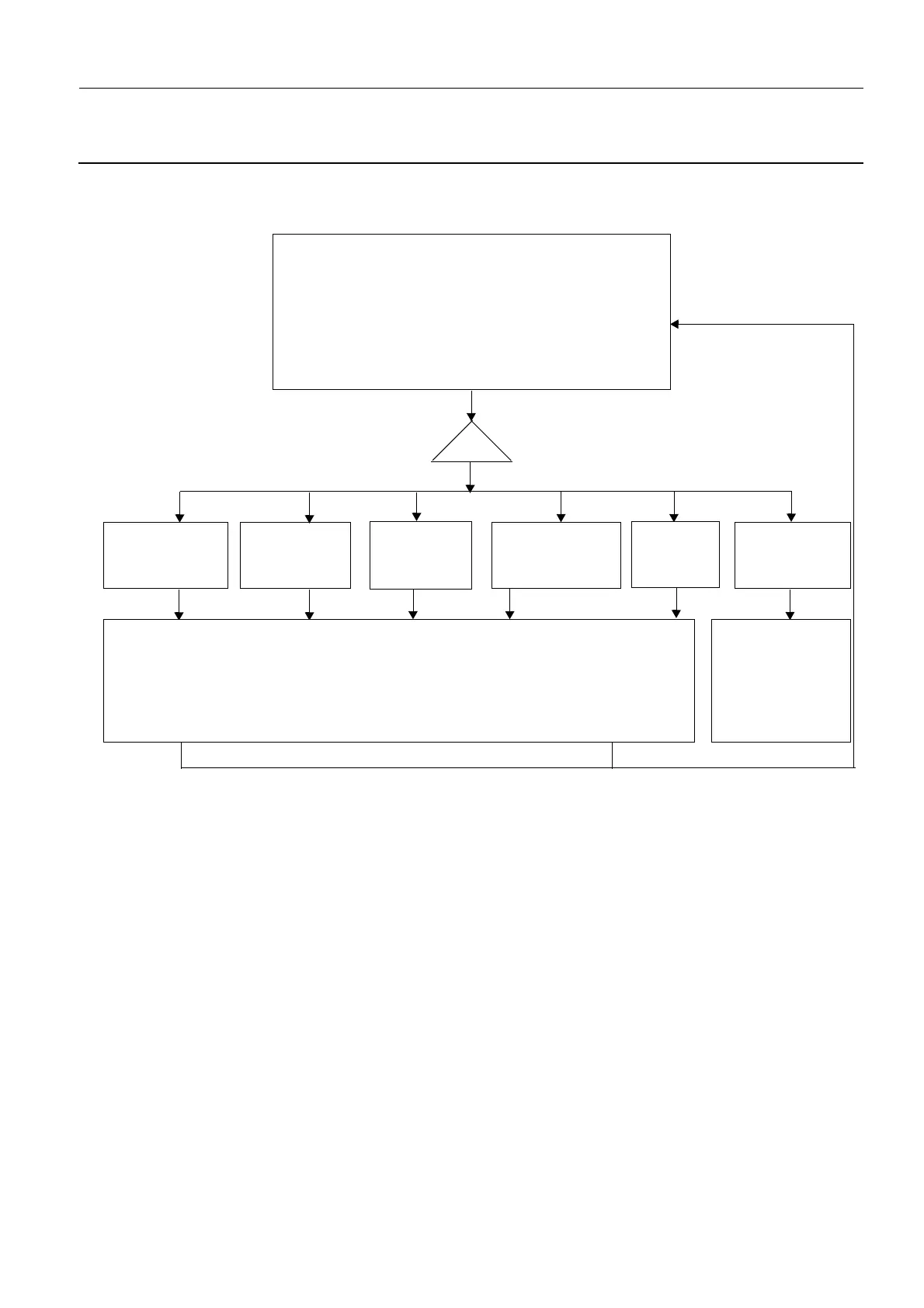

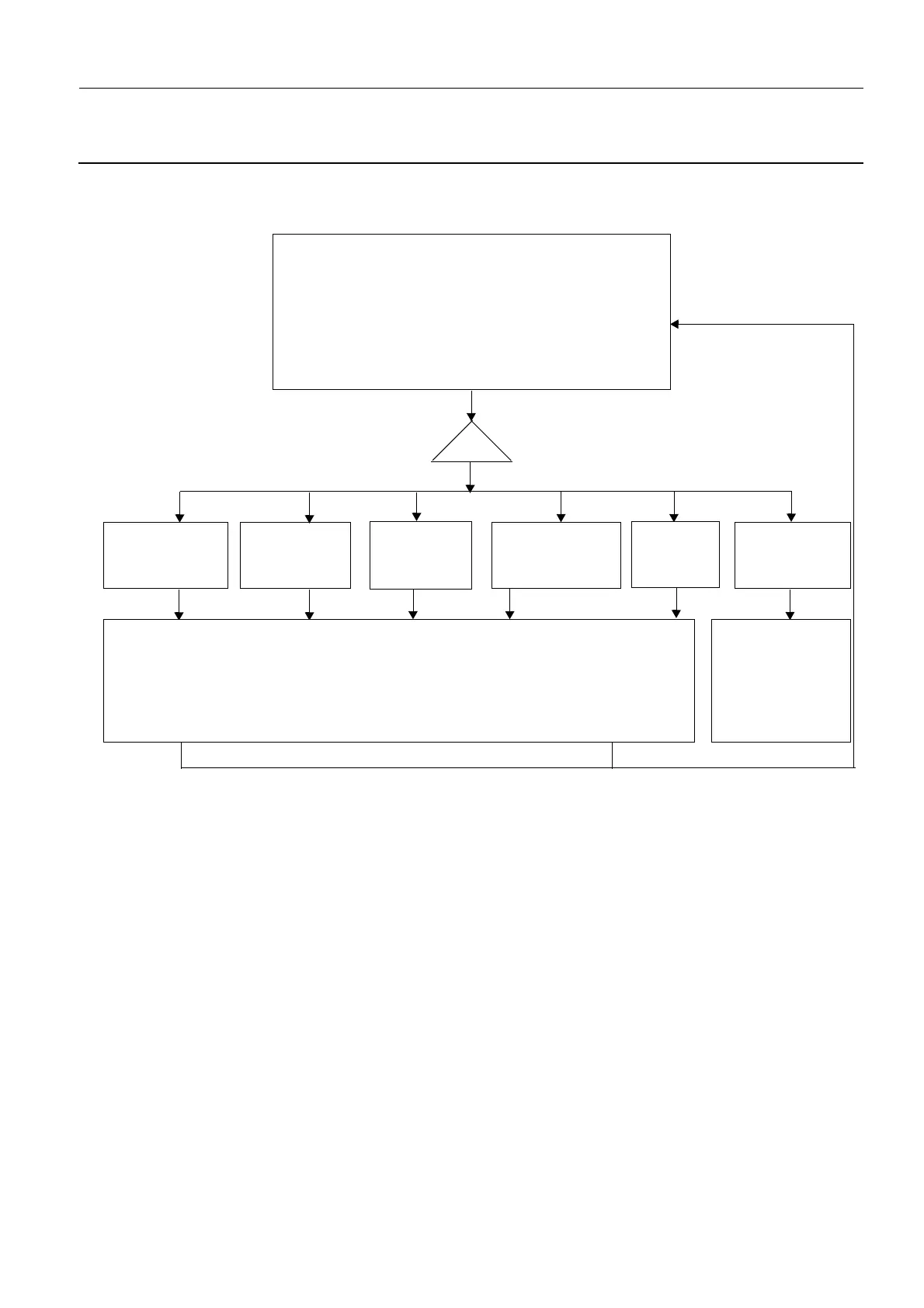

Use the following flow chart to determine the corrective actions to take.

3-6 Lift Motor Checks

Check cabling connections and connectors on the Lift Board, and the Lift Motor.

• If the Lift Motor connectors are not OK, change the Lift Motor according to Job Card D/R A205 - Lift

Motor on page 1179.

• If the Lift Board connectors are not OK, change the Lift Board according to Job Card D/R A201 - Lift

Board on page 1161.

• If the cabling connections and connectors are OK but the Lift does not still work, change the Lift

Board according to Job Card D/R A201 - Lift Board on page 1161, since it is the last remaining part

that can be replaced.

Lift Functional Checks

1. If present, remove the compression paddle.

2. Install the Bucky, and protect the Bucky surface with some paper

or similar non abrasive material.

3. Add approximately 13.5 kg (29.8 lbs) of additional weight on the

Bucky. If the Stereotaxy Positioner is present, install the Stereo-

taxy Positioner instead, and add 6 kg (13.2 lbs) of additional

weight.

4. Use the high speed Arm Control buttons to drive the Lift over the

whole range up and down 10 times in high speed.

IF

The lift moves with

high speed motion,

but the speed

changes notably.

The lift is sticking

or does not move

in particular lift

position.

The bearing

is noisy.

There is notable

or abnormal

vibration.

The motor frame or

lift screw is visibly

damaged (bent com-

ponents etc.).

The lift moves nor-

mally with no

abnormal noises

or vibrations.

Check Lift Motor

See

section 3-6, Lift

Motor Checks

.

For Type 2 Lift Screw Assembly, change Type 2 Lift without Motor (5391083), keeping the motor from the

old lift..

For Type 3 Lift Screw Assembly, change Type 3 Lift without Motor (5373048), keeping the motor from the

old lift.

See

Job Card D/R A232 - Lift Screw Assembly on page 1255.

Loading...

Loading...