Chapter 9 Page no. 880

ERR-SUB-A-003.fm

GE Healthcare Senographe DS

Revision 1 Service Information and Procedures Class A 2385072-16-8EN

ERR SUB A003 - Gantry Error Messages

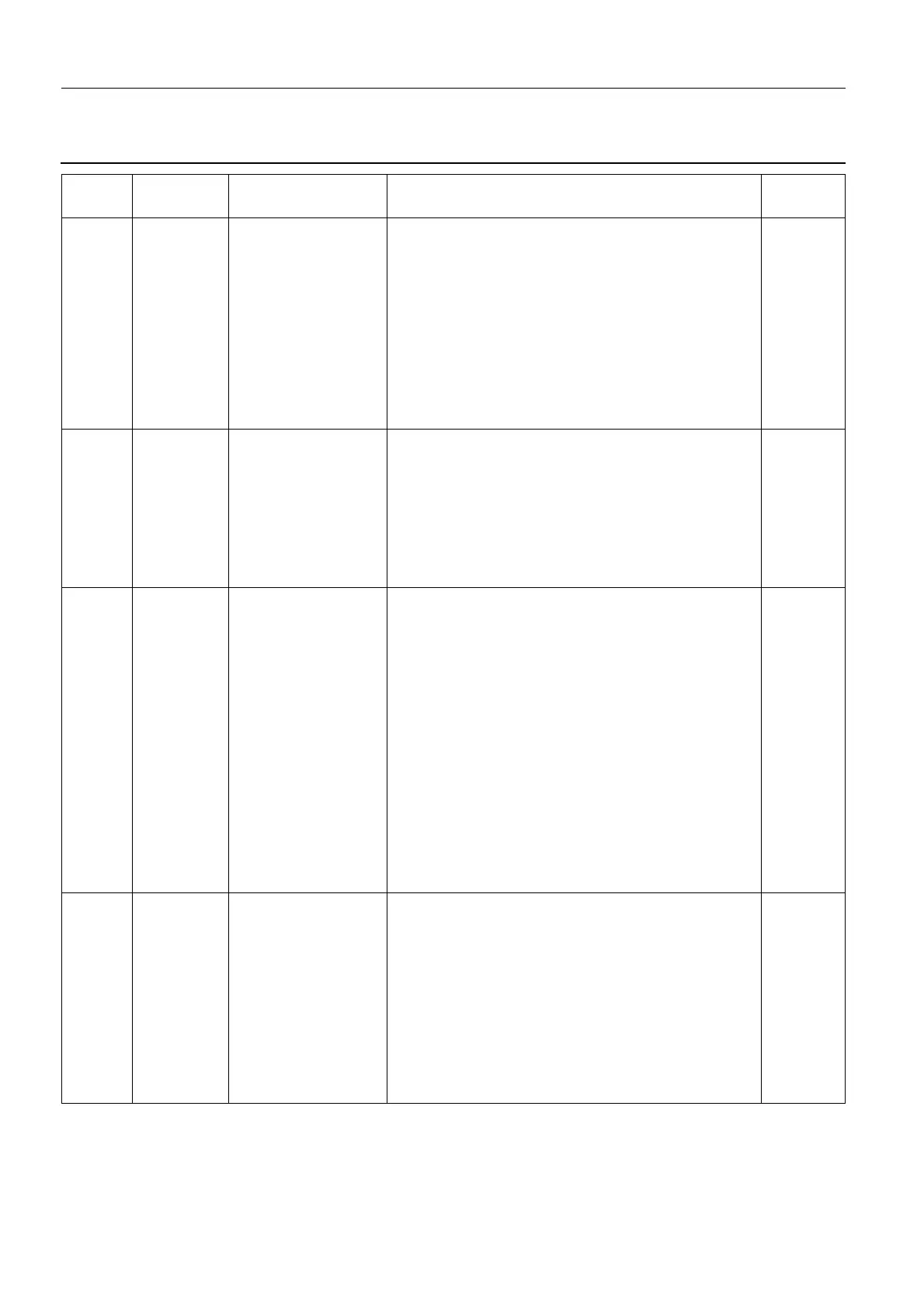

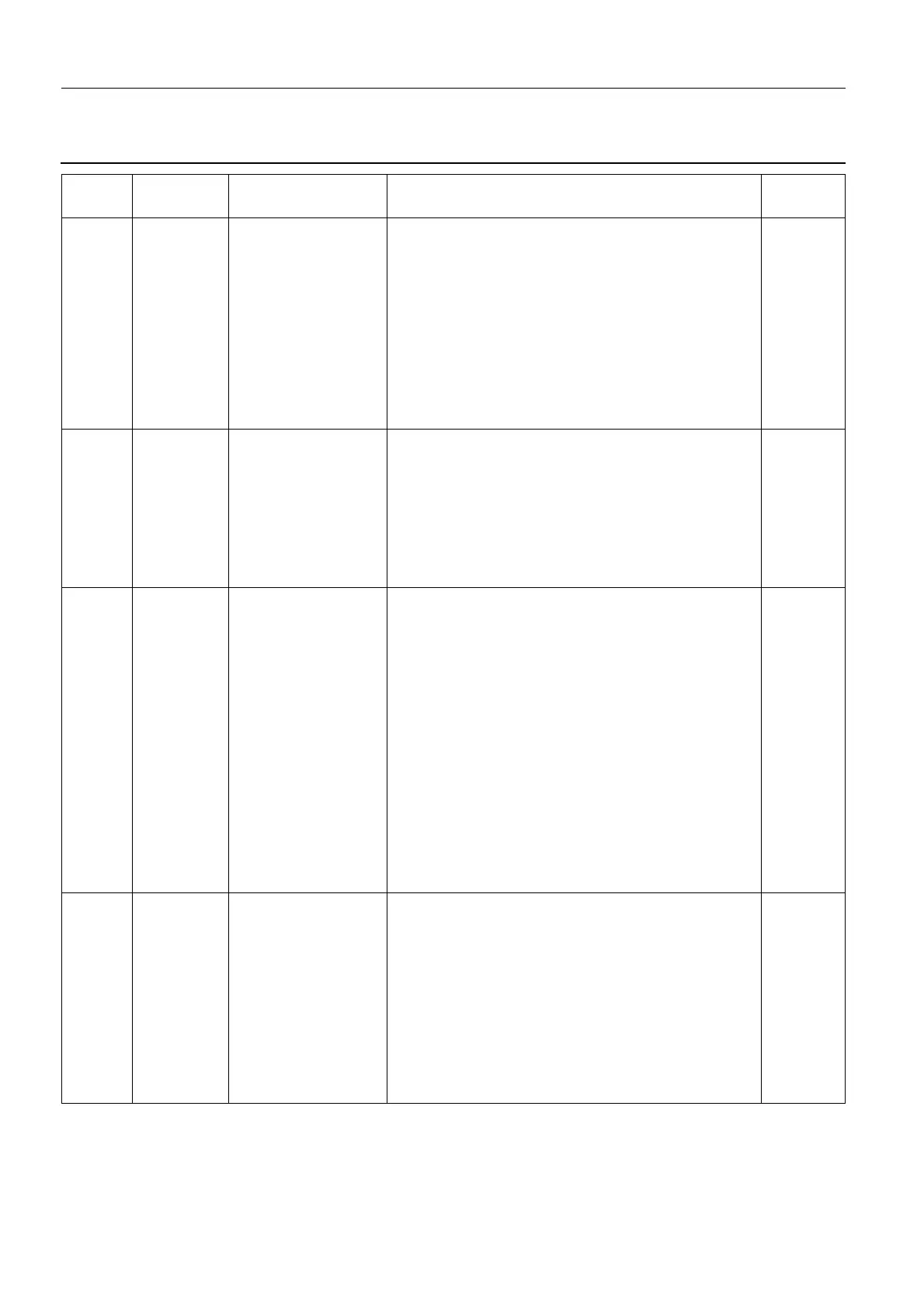

121/002 DEBUG

ONLY

COMPRESSION

SOFTWARE

ERROR

On every command sent by the PTB, the IPMS

checks whether all parameter values are compatible

with their corresponding range. If they are not within

their corresponding range, the command is ignored,

and “ParameterError” is returned to the PTB.

1. Change the Compression Board.

2. Perform a calibration of the Compression Force

Sensor.

3. Perform a Compression Thickness calibration.

D/R A250

page

1323

CAL A048

page

1709

CAL A050

page

1721

121/003 WARNING COMPRESSION

CALIB NOT

ACHIEVED

If the calibration is not achieved, for each CAN mes-

sage which is not a calibration command, the IPMS

ignores the command and sends the “CalibrationNot-

Achieved” error.

1. Perform a calibration of the Compression Force

Sensor.

2. Perform a Compression Thickness calibration.

CAL A048

page

1709

CAL A050

page

1721

121/004 WARNING NO VALID LINE

FOR COMPR

There is no valid Line. The Gantry CPU requests a

motion but node does not see the valid line. The

valid line is an RT line that is activated by the CPLD

of the node containing the UIF during the time when

the UIF is pressed + a deceleration time. This activa-

tion is a frequency put on the RT line and that is spe-

cific to the button pressed.

This also occurs when the valid line falls before the

end of the movement.

This error does not concern decompression and tilt.

Check the different motions, using all keypads to

determine the defective node. Then refer to JC DIAG

A1215 COMPRESSION CONTROL FAILURE on

page 962 to fix the problem.

A1215

page 962

121/005 DEBUG

ONLY

COMPR BUTTON

NOT PRESSED

Occurs when the CPU sends a "Start Motion" to the

node, whereas no previous command on CAN

towards the CPU was read by the node before. This

error completes the No Valid Line error because it

avoids problems due to simultaneous motions.

1. Change the Compression Board.

2. Perform a calibration of the Compression Force

Sensor.

3. Perform a Compression Thickness calibration.

D/R A250

page

1323

CAL A048

page

1709

CAL A050

page

1721

Code Category Text in Log File or

on LCD

Possible Cause/Recommended Action Job Card

Loading...

Loading...