Chapter 9 Page no. 888

ERR-SUB-A-003.fm

GE Healthcare Senographe DS

Revision 1 Service Information and Procedures Class A 2385072-16-8EN

ERR SUB A003 - Gantry Error Messages

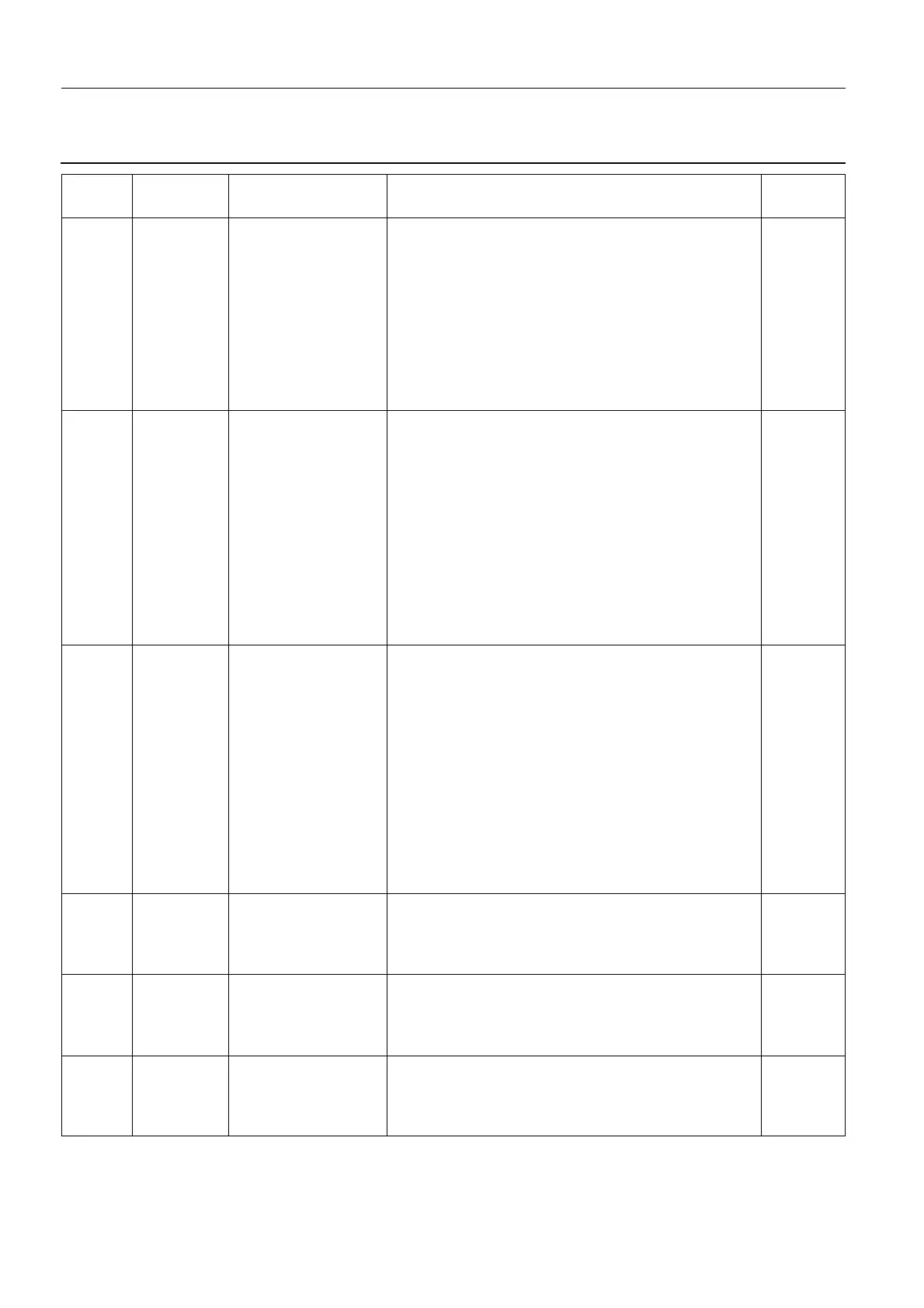

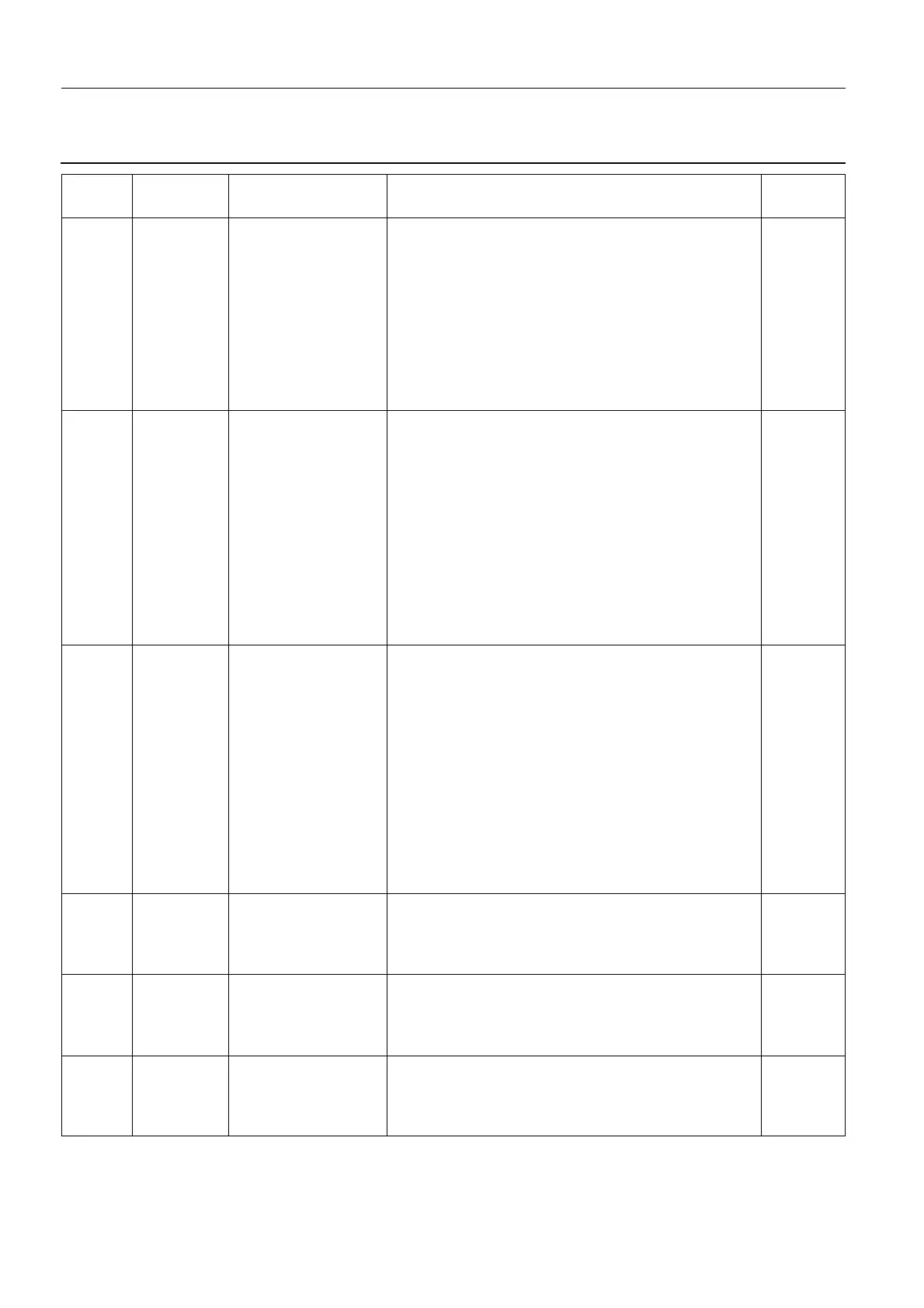

122/041 WARNING VALID LINE WAS

ACTIVE ON COM-

PRESSION NODE

The valid motion line is active at power-up.

1. Change the Gantry CPU Board (see Job Card D/

R A190 - Gantry CPU Board on page 1131).

2. Perform a Collimator Calibration (see Job Card

CAL A029 - Collimator Format Calibration on

page 1683).

3. Perform a Collimation Check (see Job Card ELE

A028 - Collimation Checks on page 679).

D/R A190

page

1131

CAL A029

page

1683

ELE A028

page 679

122/042 WARNING COMPRESSION

WAS STOPPED

WITHOUT STOP

COMMAND

The compression node stopped the motion by itself

because the button/pedal responsible for the motion

was released and no stop order was received before

the timeout.

1. Change the Gantry CPU Board (see Job Card D/

R A190 - Gantry CPU Board on page 1131).

2. Perform a Collimator Calibration (see Job Card

CAL A029 - Collimator Format Calibration on

page 1683).

3. Perform a Collimation Check (see Job Card ELE

A028 - Collimation Checks on page 679).

D/R A190

page

1131

CAL A029

page

1683

ELE A028

page 679

122/043 HALT COMPRESSION

FORCE SENSOR

FAILURE

There is a compression force sensor defect. No fre-

quency signal is detected from the compression

force sensor. IPMS_SRS_SAR_013 = In case of

defect on force sensor, the IPMS stops, and forbids

the motion, and sends an error message

IPMS_SRS_ERR_014.

Check cabling between paddle holder and compres-

sion node.

This error can be due to a too high reverse force

applied on the paddle. If the reverse force is too sen-

sitive, the Faulty FRU is the Compression trolley kit.

A1213

page 961

122/044 DEBUG

ONLY

COMPRESSION

INVALID

RX_OPTICAL_FOR

K1_ERROR

Ignore this error. If the problem persists, contact your

OLC.

122/045 DEBUG

ONLY

COMPRESSION

INVALID

RX_OPTICAL_FOR

K2_ERROR

Ignore this error. If the problem persists, contact your

OLC.

122/046 DEBUG

ONLY

COMPRESSION

INVALID

LIFT_DOWN_PEDA

L_ERROR

Ignore this error. If the problem persists, contact your

OLC.

Code Category Text in Log File or

on LCD

Possible Cause/Recommended Action Job Card

Loading...

Loading...