96-8000 185

G CODES

June 1999

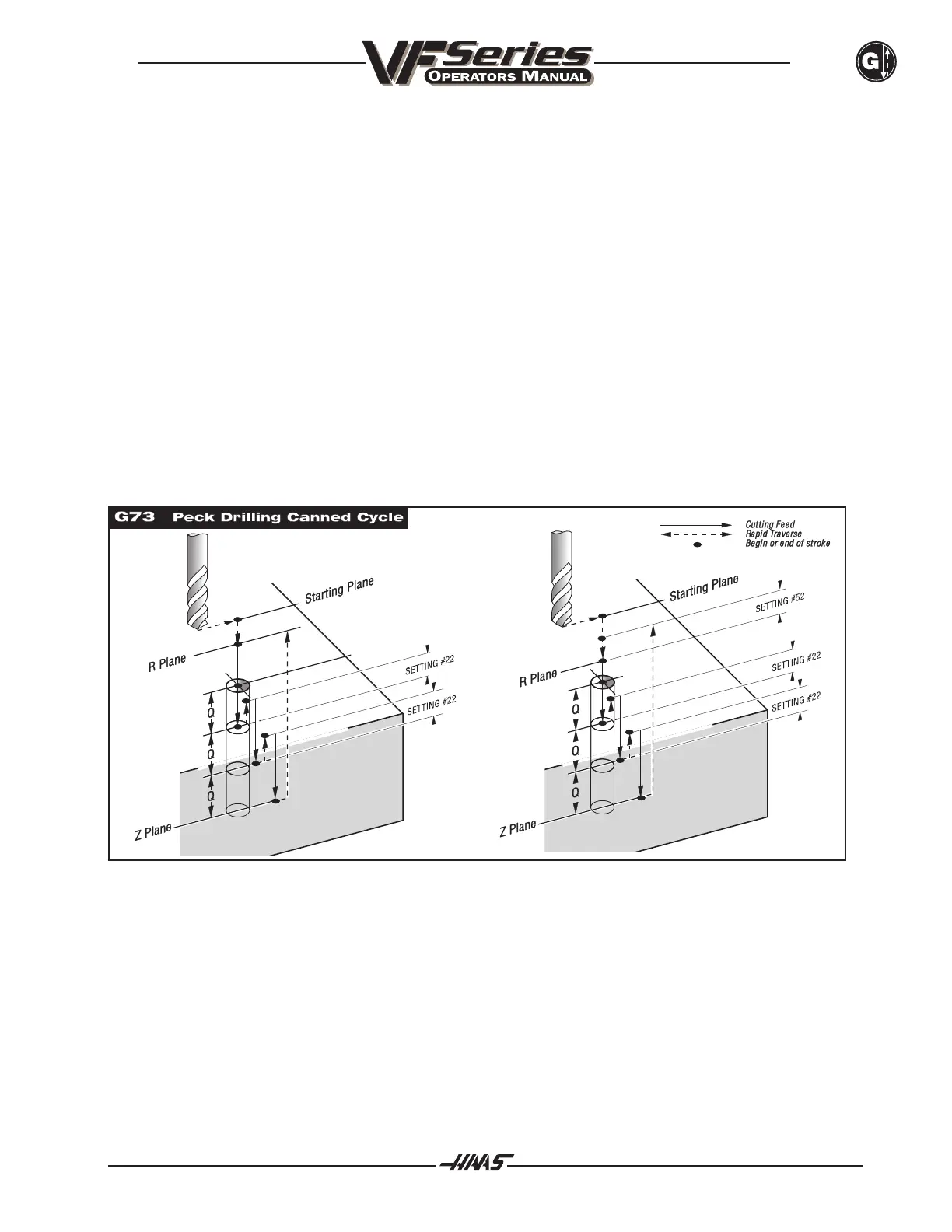

This G code is modal in that once activated, every motion of X and/or Y will cause this canned cycle to be

executed until it is canceled or another canned cycle is selected. This cycle is a high speed peck cycle where

the retract distance is set by Setting 22.

If I, J, and K are specified, a different operating mode is selected. The first pass will cut in by I, each succeed-

ing cut will be reduced by amount J, and the minimum cutting depth is K. If P is specified, the tool will pause

at the bottom of the hole after the last peck for that amount of time.

The same dwell time applies to all subsequent blocks that do not specify a dwell time. When the canned

cycle is cancelled (i.e. G00, G01, G80, RESET) the dwell time will be reset to zero. This dwell cannot be used

in the same block as an M97, M98, M99, or G65, because these codes use P for different purposes.

If K and Q are both specified, a different operating mode is selected for this canned cycle. In this mode, the

tool is returned to the R plane after a number of passes totals up to the K amount. This allows much faster

drilling than G83 but still returns to the R plane occasionally to clear chips.

I, J, K, and Q are always positive numbers.

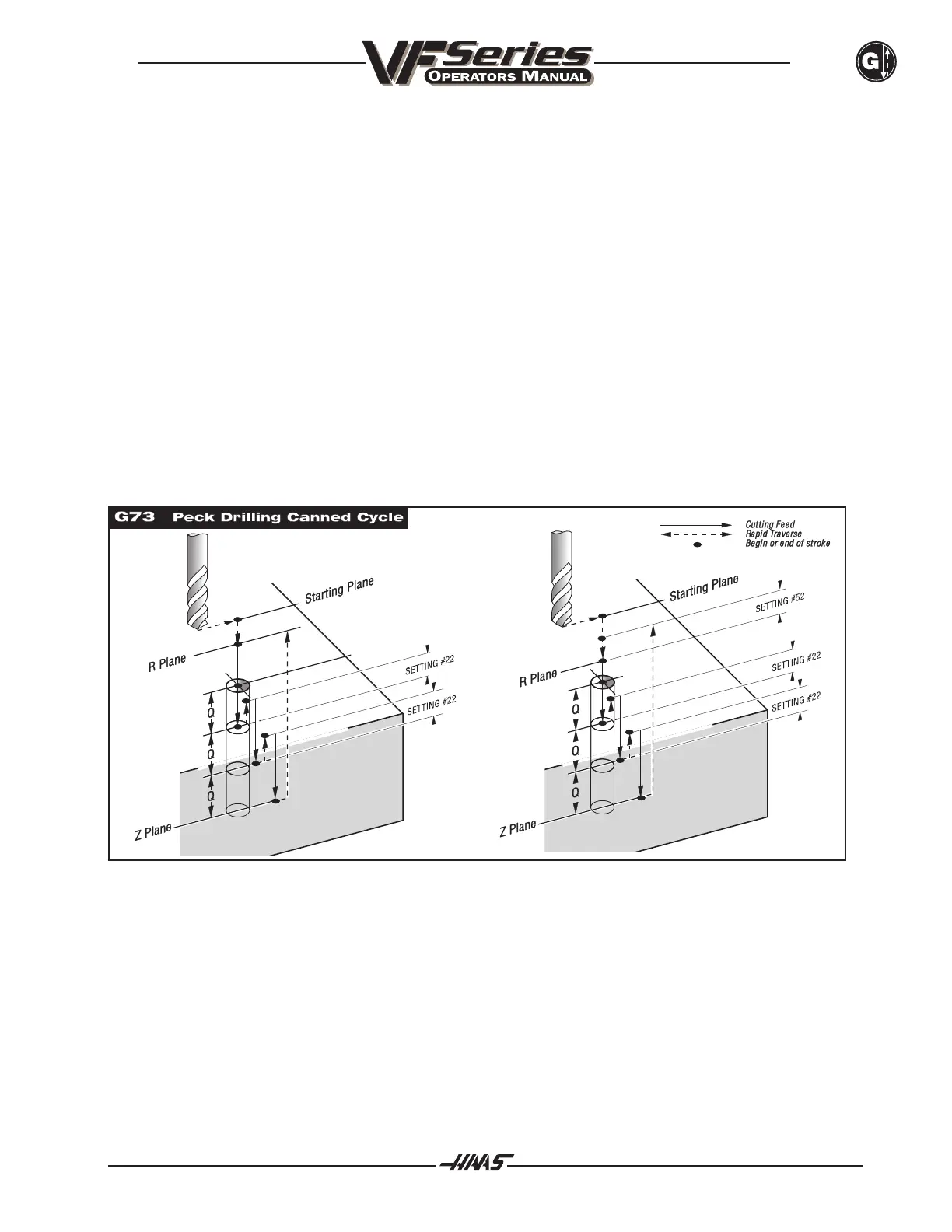

Setting 52 also changes the way G73 works when it returns to the R plane. Most programmers set the R plane

well above the cut to ensure that the chip clear motion actually allows the chips to get out of the hole but this

causes a wasted motion when first drilling through this empty space. If Setting 52 is set to the distance

required to clear chips, the R plane can be put much closer to the part being drilled. When the clear move to R

occurs, the Z will be moved above R by this setting.

Loading...

Loading...