Page 84 SLG 700 SmartLine Level Transmitter User’s Manual Revision 8

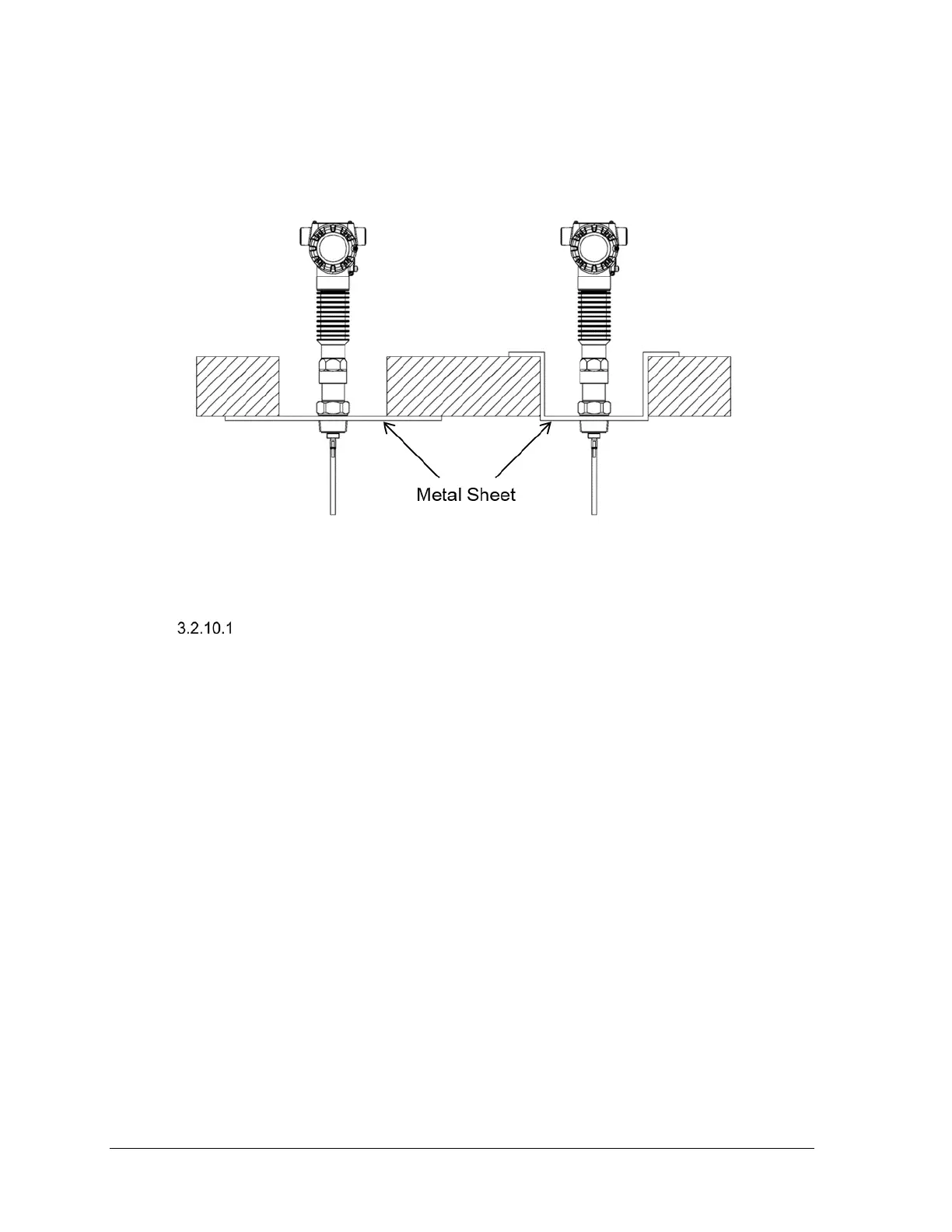

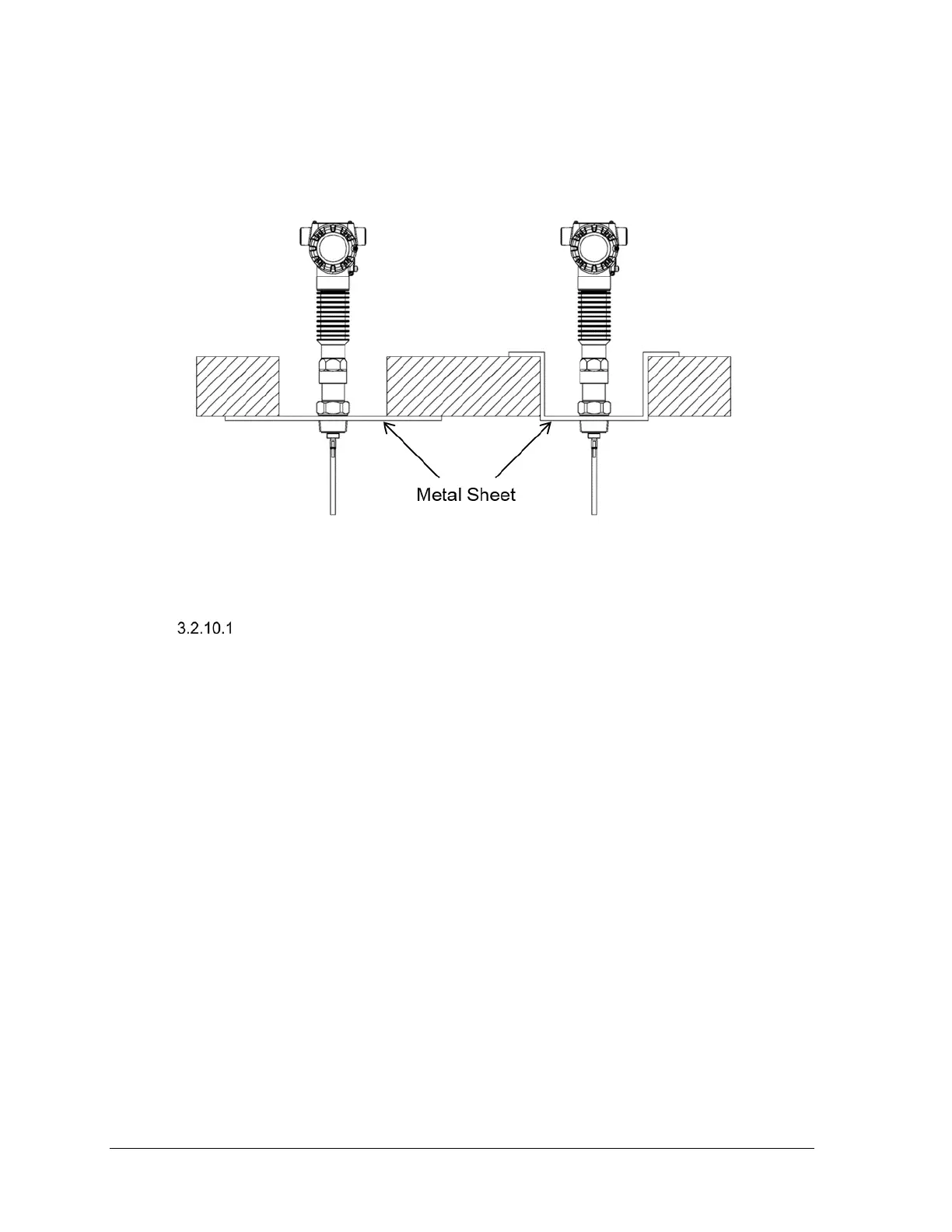

Figure 3-38 depicts an example of mounting in concrete silos, the placement of the concrete

versus the metal sheet used to secure the transmitter. Both Figure 3-37 and Figure 3-38 are

considered non-metallic mounts. Both types of mountings are subject to the same

specifications.

Figure 3-38: Mounting in concrete silos

Remote mount

In applications where a remotely mounted display is required, the remote mount allows

the electronics housing to be mounted 3-m away from the process connector. This can be

useful when access to the mounting location is limited. To assemble the remote mount,

mount the process connector to the tank first, then secure the mounting bracket to a pipe

or wall. Secure the electronics module to the bracket with the 3 supplied M6 screws.

Connect the cable and check bends for minimum radius (see Figure 3-39) to prevent

damage. Torque the 2 nuts to 6Nm (4.4ft-lbs). Note that if separating the cable from the

process connector or the electronics, care must be taken to avoid damaging the o-rings.

O-ring lubricant may help to avoid damage.

Loading...

Loading...