4-14 ArcGlide THC Instruction Manual

MAINTENANCE

To update ArcGlide software:

1. After you download the AGUpdater.zip file, unpack it in a directory on the laptop hard drive or on a memory stick.

One of the files included will be “EthernetSetup.vbs”. There will also be some program image .bin files and Update.

exe files to load the images.

2. Plug the laptop into the devices that you want to update

or the Ethernet switch if you want to update multiple

units.

3. Navigate to the directory where you downloaded the

files

4. Double click-on the EthernetSetup.vbs file.

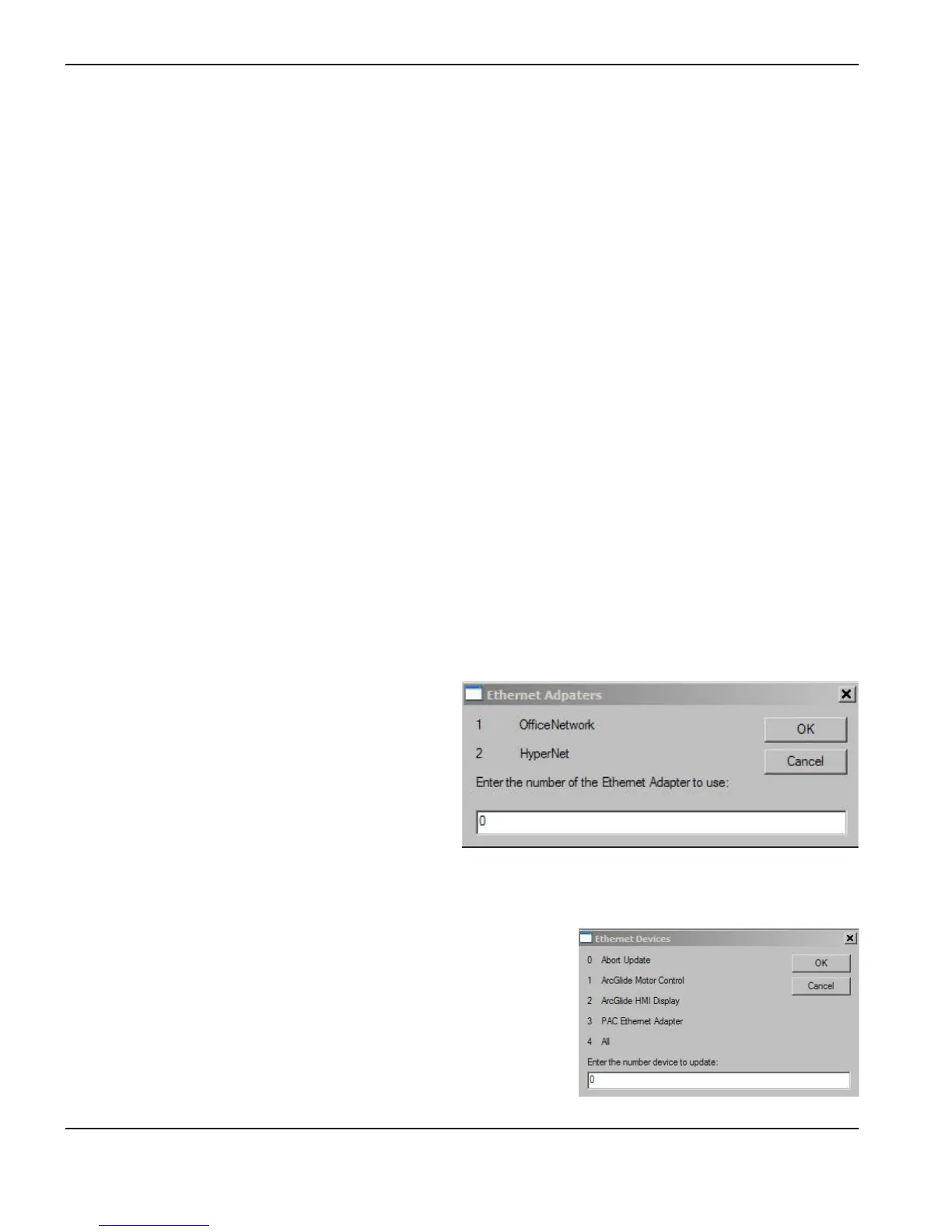

A dialog box displays that lists the Ethernet ports that

are installed on the computer.

5. Enter the number of the adapter that you want to use to

update the ArcGlide unit.

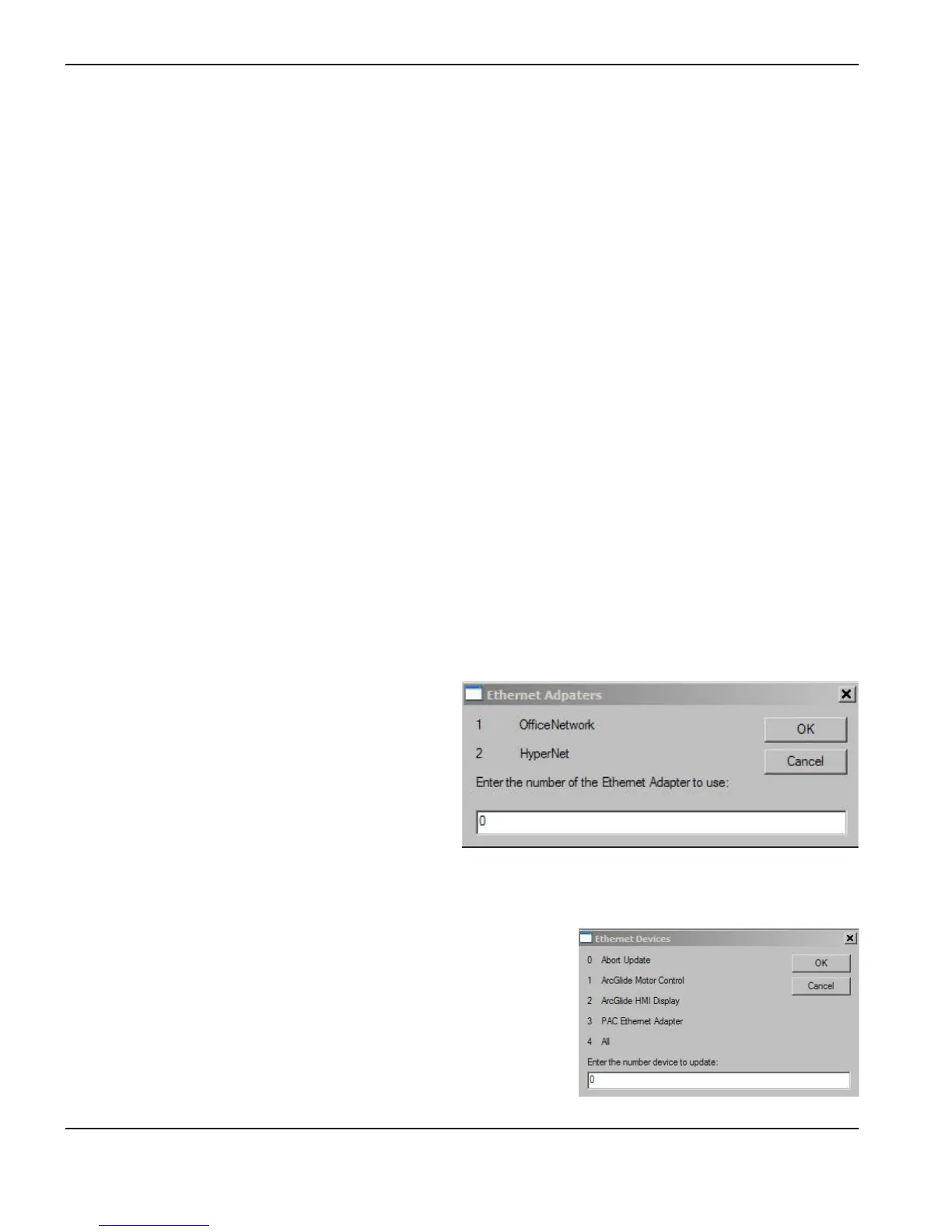

6. After a short delay, a dialog box displays with a list of the devices you can

update.

7. Enter the number of the device that you want to update from the list on

the dialog box.

Select 0 to exit without updating.

8. When the update process is complete, the program returns the network

settings to their original settings and exits.

Update ArcGlide software

Download through Phoenix software

To download software updates for the ArcGlide system using Phoenix software, the ArcGlide must be powered on and

connected to a Hypertherm CNC by Hypernet. You can update directly from the CNC.

To update directly from the CNC:

1. Load the Update.exe file onto a flash drive.

2. Insert the flash drive into the USB port in the CNC.

3. From the Main screen in Phoenix software, select Setups > Password and enter the Special password.

4. On the Special Password screen, press the Update Software softkey.

The CNC updates the Phoenix software and sends ArcGlide software updates to each ArcGlide unit.

Download from a laptop

If your configuration does not include an EDGE Pro CNC or the correct interface with the ArcGlide, you can download

the AGUpdater.zip file from Hypertherm. This file contains the program and script files necessary to update the ArcGlide

components.

Loading...

Loading...