4-10 ArcGlide THC Instruction Manual

MAINTENANCE

2

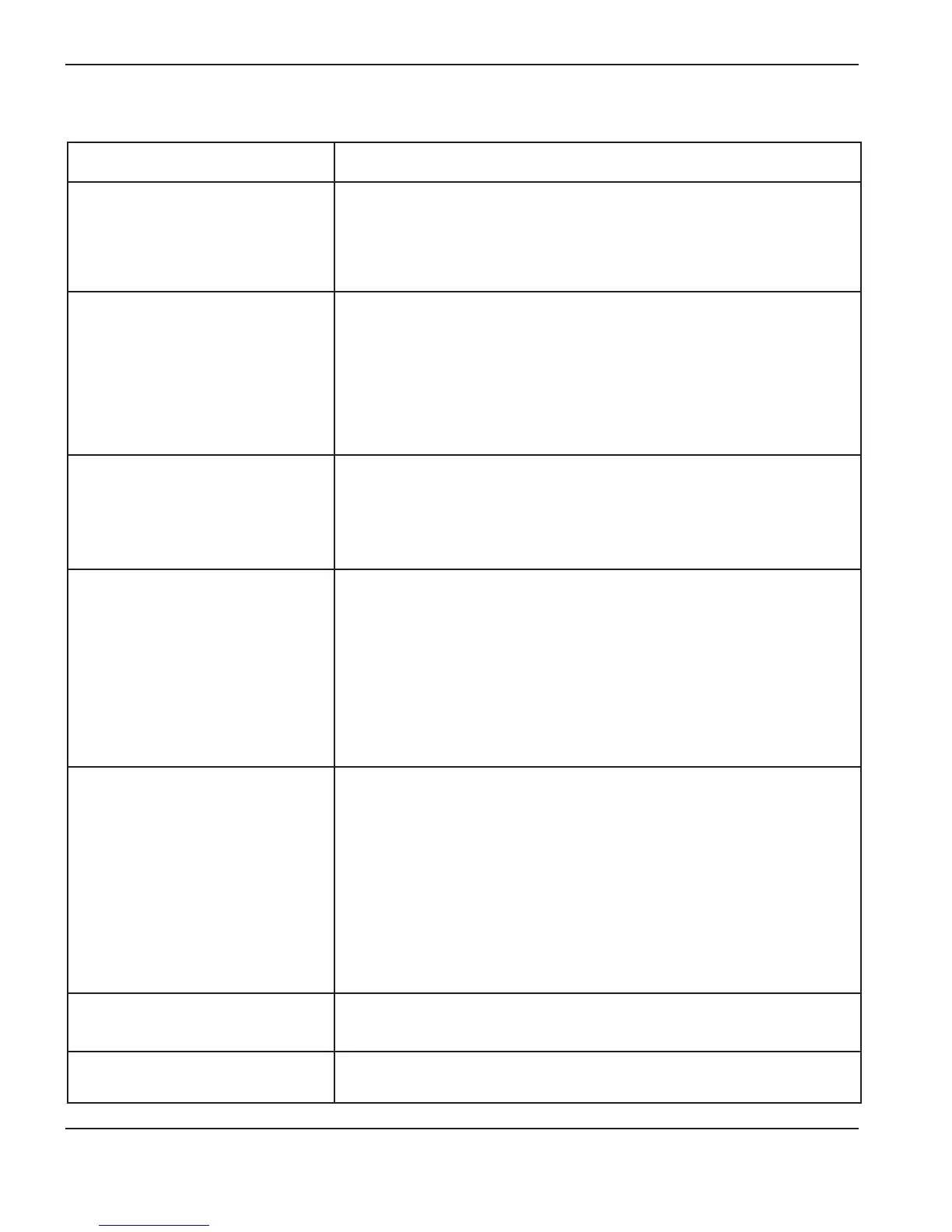

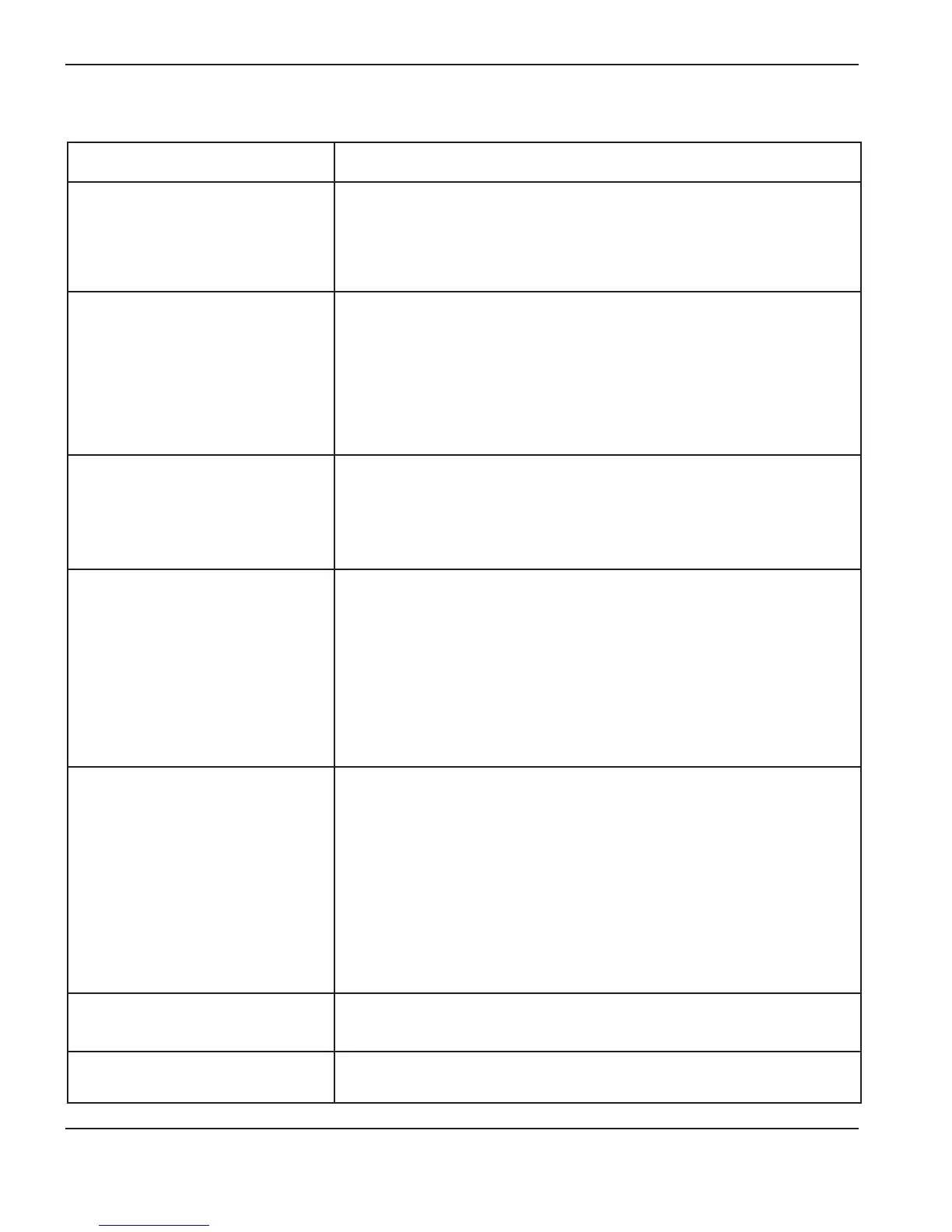

Fault Possible causes

Failure to transfer.

1. Work cable connection on the cutting table is not making good contact.

2. Torch-to-work distance is too high.

3. The surface of the workpiece is rusty, oiled, or painted.

Failed to completely pierce the

workpiece and there is excessive

sparking on top of the workpiece.

1. Current is set too low (check Cut chart information).

2. Cut speed is too high (check Cut chart information).

3. Torch parts are worn (change consumable parts).

4. Metal being cut is too thick.

5. The surface of the workpiece is rusty, oiled, or painted.

6. Pierce Delay is set too low.

Dross forms on the bottom of the cut.

1. Cutting speed is not correct (check Cut chart information).

2. Arc current is set too low (check Cut chart information).

3. Torch parts are worn (change consumable parts).

Cut angle is not square.

1. Wrong direction of machine travel. The high-quality side is commonly on the

right with respect to the forward motion of the torch.

2. Torch-to-work distance is not correct (check Cut chart information).

3. Cutting speed is not correct (check Cut chart information).

4. Arc current is not correct (check Cut chart information).

5. Damaged consumable parts.

6. The torch is not mounted perpendicular to the workpiece.

7. Damaged torch.

Short consumable life.

1. Arc current, arc voltage, travel speed, motion delay, gas flow rates, or initial

torch height was not set as specified in the cut charts.

2. Attempting to cut highly magnetic metal workpiece, such as one with a

high nickel content, will shorten consumable life. Long consumable life

is difficult to achieve when cutting a workpiece that is magnetized or

becomes magnetized easily.

3. Beginning or ending the cut off the surface of the workpiece. To achieve

consumable long life, all cuts must begin and end on the surface of the

workpiece.

Torch does not fire.

The torch is not enabled. For HPR and HPR XD plasma systems, verify that

Remote On is wired correctly on the plasma interface. For more information,

see Hypernet plasma interface (141161) in this section.

Part is the wrong size. The Kerf value is set incorrectly.

Common cutting faults

Loading...

Loading...