2-34 ArcGlide THC Instruction Manual

INSTALLATION

2

It is also possible to have a mixed Hypernet and discrete configuration in which the ArcGlide THC communicates with

only the CNC or plasma system over Hypernet and uses discrete communication for the alternate link. Use the portions

of the following instructions that apply to your configuration.

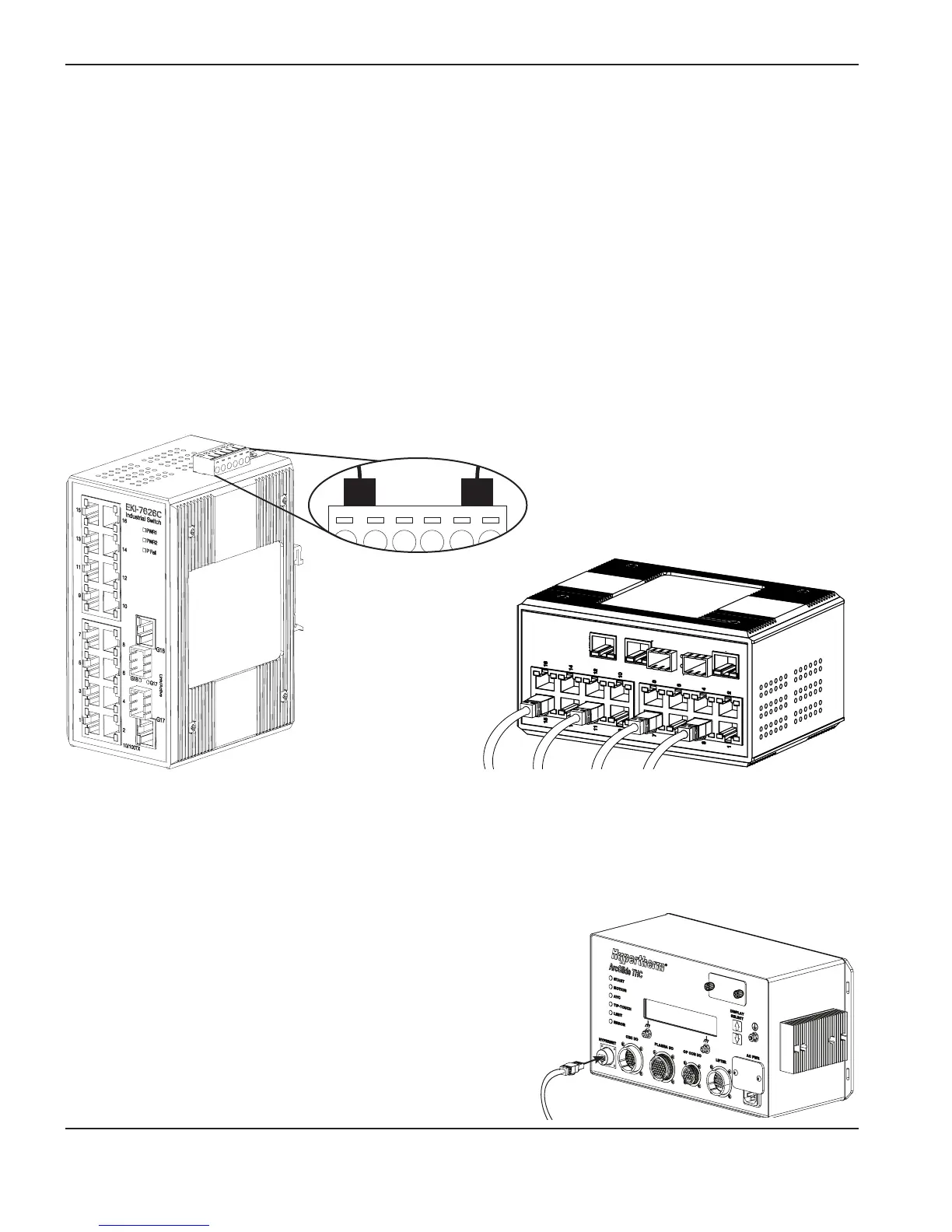

1. Use a Hypernet cable to connect the control module

to the Ethernet switch:

a. Insert one end of the Hypernet cable into the

Hypernet connector on the front of the control

module.

b. Insert the other end of the cable into one of the

ports of the Ethernet switch.

Connect Hypernet cables

A system configuration in which there is more than one Hypernet span requires an industrial-grade Ethernet switch. For

more information on the requirements for this switch, see Specifications.

In this type of configuration, the Hypernet links are made from the ArcGlide directly to the Ethernet switch and from

there to the CNC or plasma system. See System description for a Hypernet configuration, earlier in this section.

Notes: Each unit that is assigned to a station must have the same Hypernet unit address. This common unit

address allows the Ethernet switch to direct communications to the units at the appropriate station.

See the Maintenance section for the location of the unit address switches on the PCBs.

Hypernet connections and Ethernet connection to a LAN cannot be made through the same switch. If

your cutting system is connected to a LAN over Ethernet, you must use a separate Ethernet switch for

these connections.

Hypernet connections to the Ethernet switch

To the Ethernet switch

Power connections to the Ethernet switch

To power supply 2

To power supply 1

+

- -

+

Loading...

Loading...