ArcGlide THC Instruction Manual 2-23

A

17

18

INPUT 12

OUTPUT 10

OUTPUT 11

OUTPUT 12

5

7

1

26

25

INTERLOCK

12

32

31

30

MOTION

CYCLE START

AVC DISABLE

IHS SYNC

24V COMMON COMMON

31

24V

PULL UP

24V

PULL UP

24V

PULL UP

CYCLE START

RELAY

RELAY

BREAKAWAY

BREAKAWAY

37

11

INPUT 11

22

21

COMMON

JUMPER

JUMPER

COMMON

29

30

TORCH

B

D S D S

CNC PLASMA

INPUT

24V

+24V

+24V

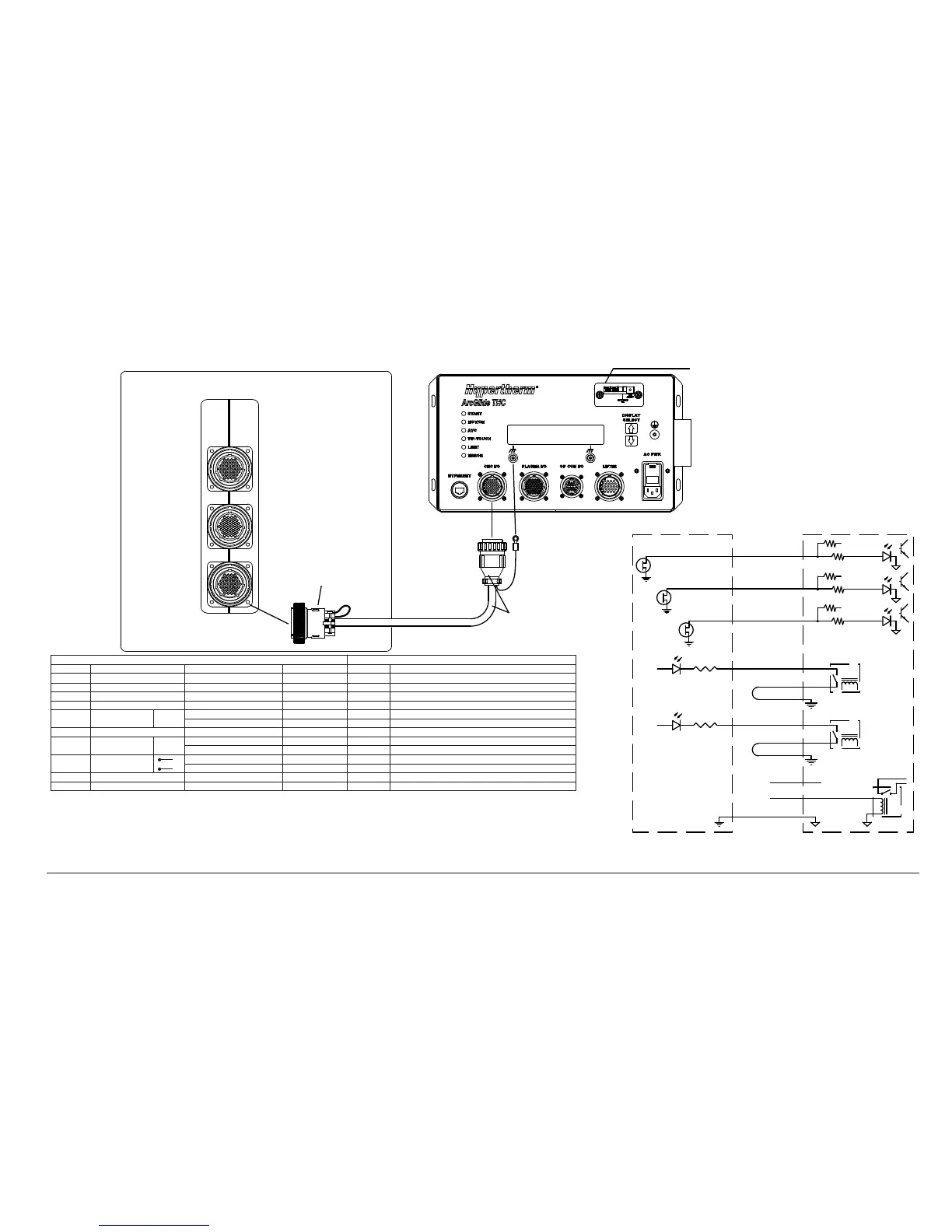

ArcGlide CNC interface with discrete connection to a Picopath CNC

ArcGlide control

module

Set dry contacts by sliding

the switch to D.

ArcGlide CNC

interface cable

CNC with Picopath interface

Picopath connector kit

(228490)

Axes 3, 4

Axes 1,2

I/O

Picopath CNC end A

ArcGlide control module end B

Picopath CNC end (A), terminated during installation ArcGlide end (B), terminated by Hypertherm

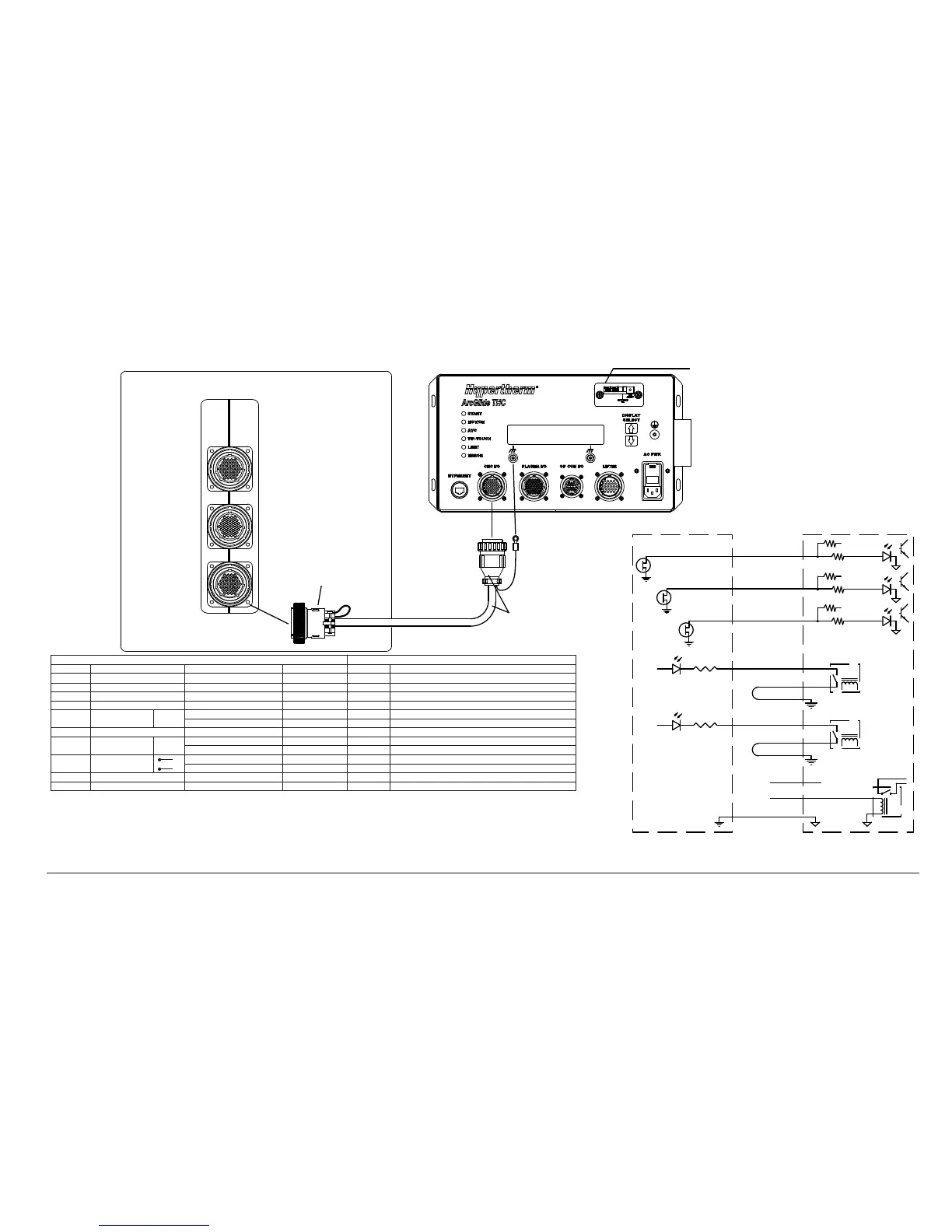

Pin Function Phoenix mapping name Wire color Pin Signal

32 Output 12 Cut control Red 1 Cycle start input+

31 Output 11 Hold ignition Blue 7 IHS sync input+

30 Output 10 Torch height disable Green 5 AVC disable input +

12 Input 12 Cut sense 1 Green 17 Machine motion output A

Jumper together

⊂

Red 18 Machine motion output B

Blue 29 Common

11 Input 11 Torch collision Yellow 21 Torch breakaway output A

Jumper together

⊂

Red 22 Torch breakaway output B

Green 30 Common

External switch

Orange 25 Interlock input+

Red 26 Interlock input -

37 24 V Common Yellow 31 Common

Backshell Ground Ground

• Start with Hypertherm-supplied ArcGlide CNC interface cable and terminate the Picopath end.

• This example uses CNC outputs 10, 11, 12, and inputs 11 and 12. Map I/O in Phoenix software accordingly.

• Multiple wires are the same color. Verify pin-to-pin connections before plugging cables into equipment.

• Incorrect wiring can cause permanent damage to Picopath or ArcGlide circuits.

• Set ArcGlide CNC inputs to dry with the slide switch on the control module.

• ArcGlide interlock must be satisfied (closed) to enable ArcGlide motion.

2

Loading...

Loading...