EN

4 - HANDLING AND INSTALLATION Master 80 UP HyperFlexible

4 - Pag. 14 / 14

ALIGNMENT

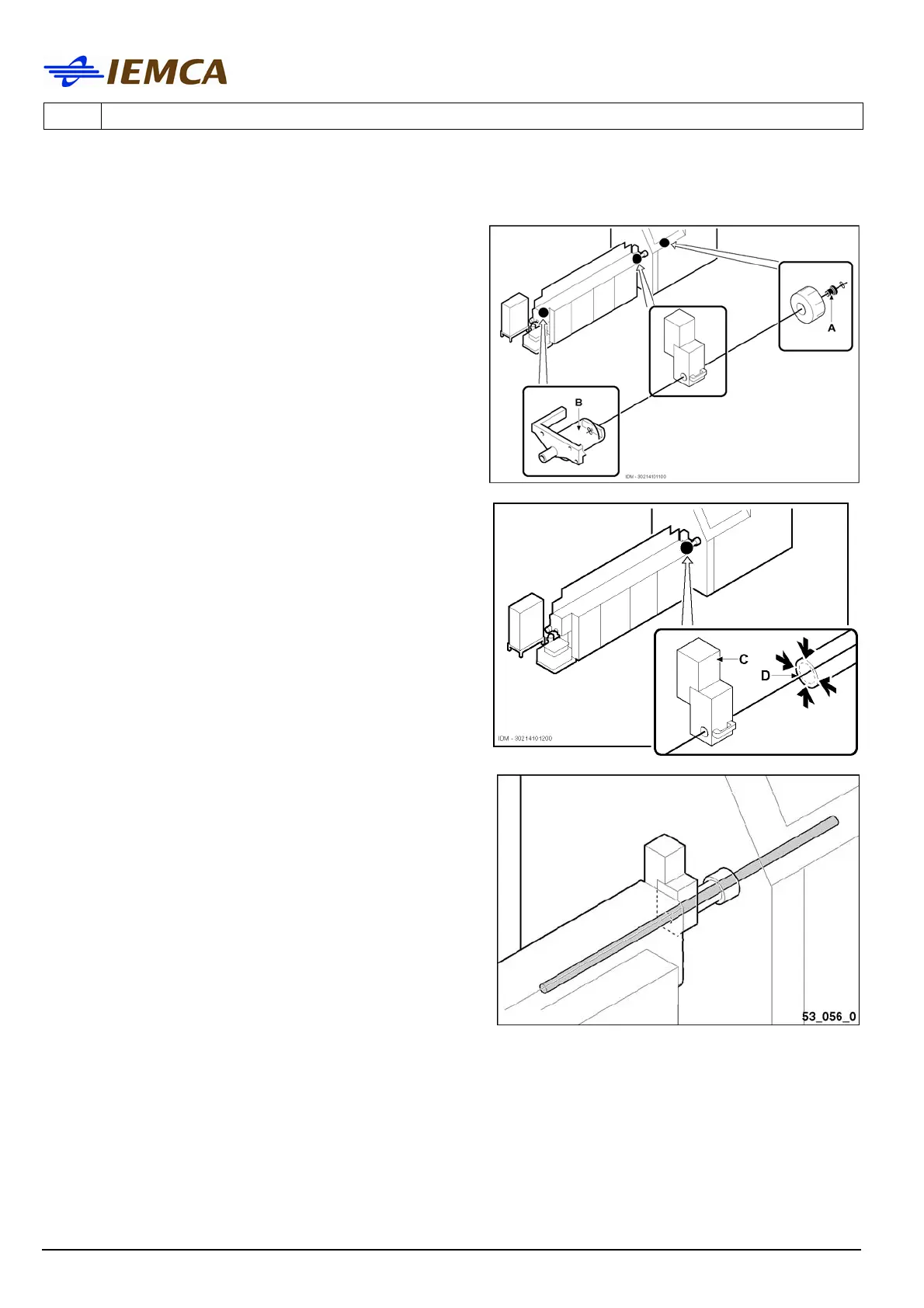

The alignment is obtained by fitting a nylon thread

(ø 1 mm) between the lathe collet and the first

feeding carriage, proceeding as follows:

• place a drilled bush (A) in the lathe collet;

• stretch the thread between the bush and the

hole in the first feeding carriage (B).

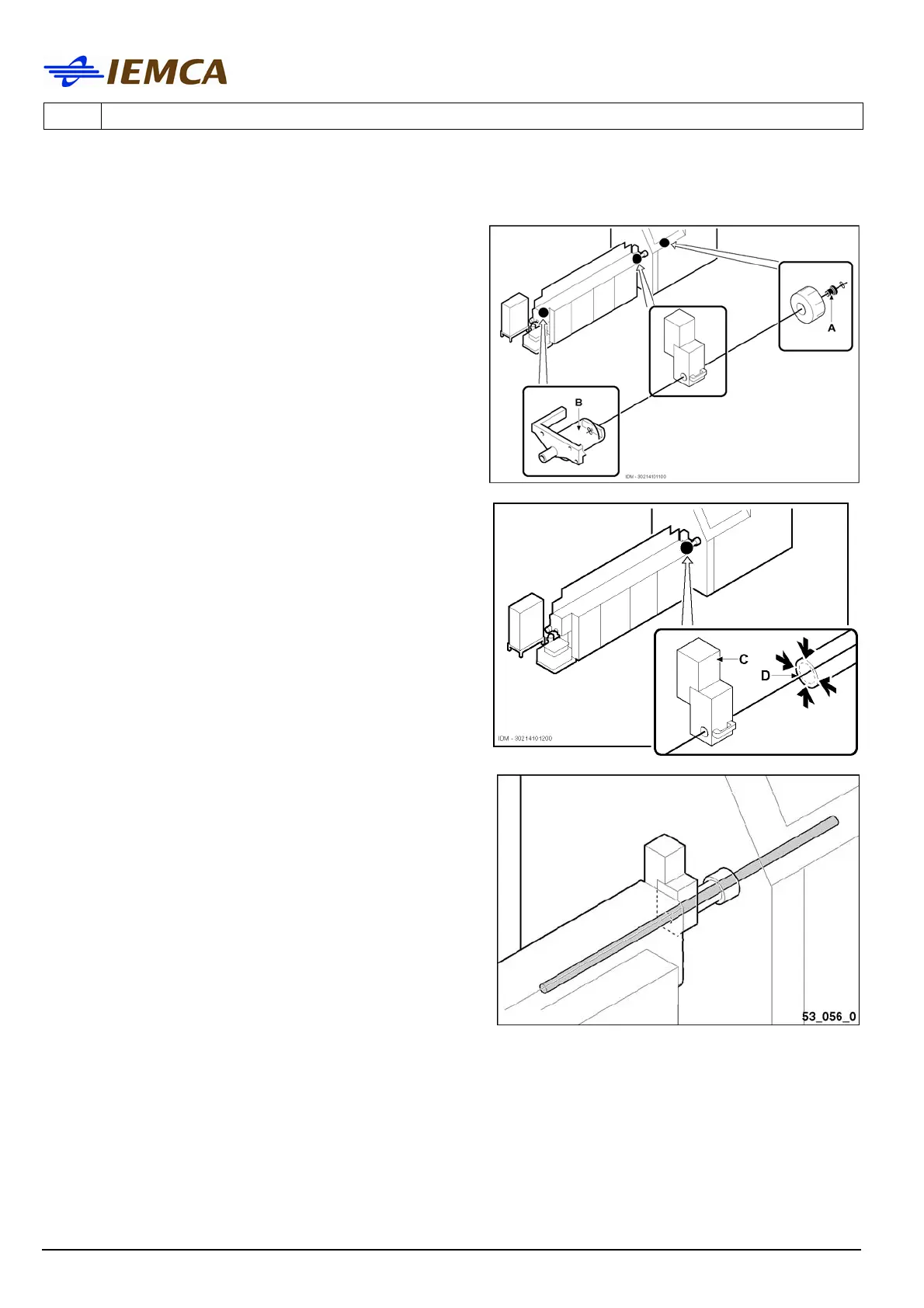

• check with a sliding caliper, the alignment near

the bush (C) and the spindle (D); use a

tolerance of ± 0.15 mm in the four directions.

It is also possible to carry out the alignment by

placing a bar in the guide channels. Proceed as

follows:

• prepare a perfectly straight ground bar, with an

external diameter equal to the maximum spindle

bar passage and with a length equal to the

double coupling distance (see (B) in section

4.4.3);

• place the bar in the guide channel and cause it

to slide forwards and backwards in the spindle,

until the lathe collet area is reached.

Loading...

Loading...