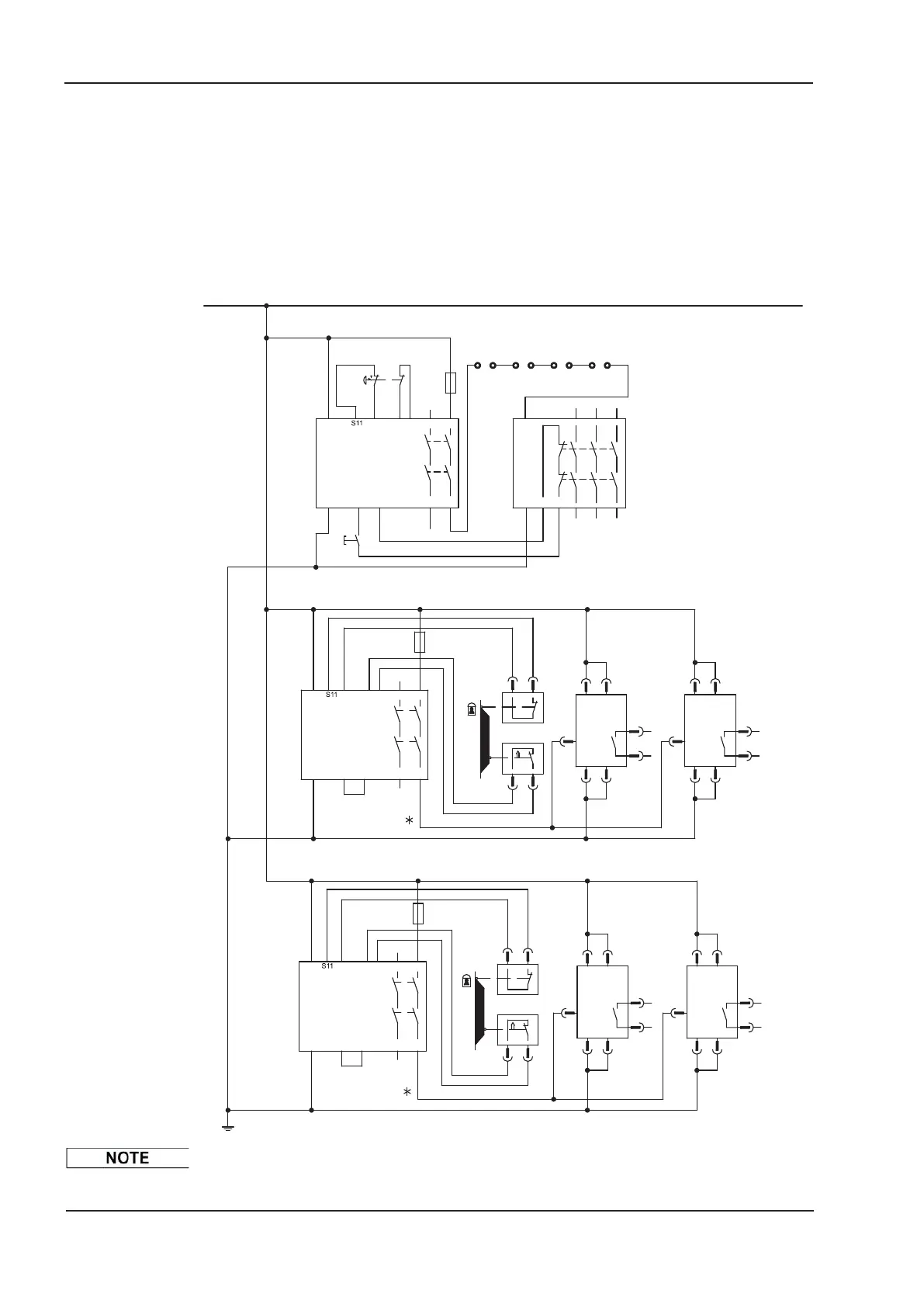

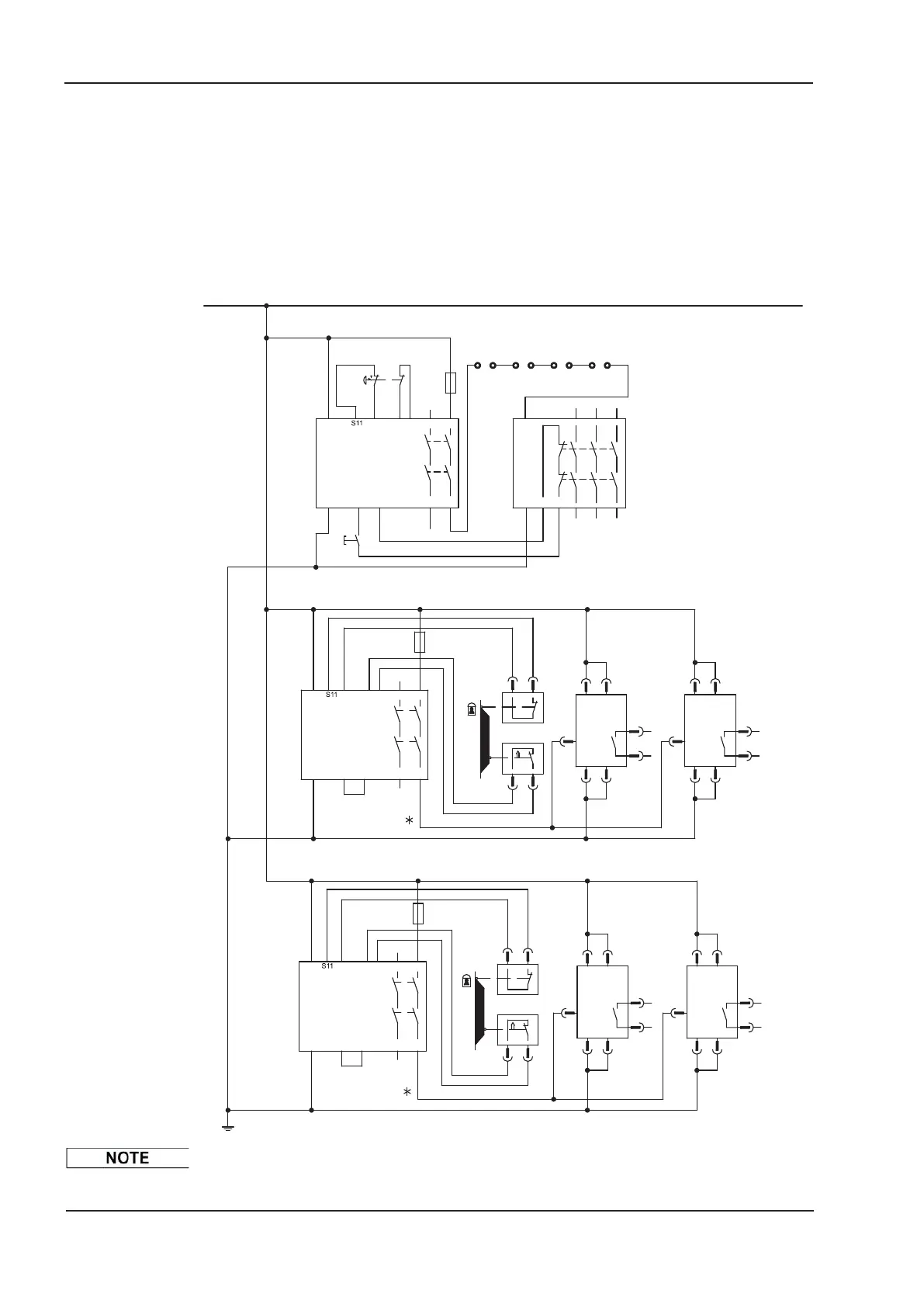

6.9.8.2 Control circuit

The example shows a circuit diagram with two separated work areas connected to one

emergency stop circuit. For each work area individually "safe stop" of the drives is

switched by a protective screen.

The safety switch gears used in the example are manufactured by Pilz and fulfill at least

the PL d acc. to ISO 13849-1. Further information to the safety switch gears is available

from Pilz. The use of safety switch gears of other manufacturers is possible, if these also

fulfill the SIL CL 2 according to IEC 62061 and PL d according to ISO 13849-1.

Consider the wiring instructions on page 39.

42 S300 Instructions Manual

Technical description 02/2017 Kollmorgen

24

12

0V

K4

S6

23

STO-Enable

23

24

S21

S34A2

A1

S12

14

S22 13

F3

A2 S34 14

S5

11

STO-Enable

24

S4

23

K3

+24VDC

S21A1 S12 S22 13

F2

23

S3

11

12 12

X4

1

X4

1

1

2

2

1

2

2

5

X4

X4

BTB

4

3

X4

2

1

24

5

BTB

4

3

X4

5

X3

X4

X4

BTB

4

3

X4

2

1

5

BTB

4

3

X4

X3

12

2

1

X4

X3

2

1

X4

12 12

X3

*

*

BTB

A1

A2

K1

13

14

Reset

-S1

A2 S12 S34 2414

S22

E-Stop

PNOZ S3

A1

-S2

S21S12 2313

F1

K2

BTB

12

Y2Y1

BTB

3

BTB

4

PNOZ S3

PNOZ S3

S12

S12

contactor

Mains

Drive 1 Drive 2

Drive 5Drive 4

Emergency-stop circuit

acc. to ISO 13849-1 PL e

Safe stop acc. to ISO 13849-1 PL d, single channel, group 1 for 2 drives

Safe stop acc. to ISO 13849-1 PL d, single channel, group 2 for 2 drives

Loading...

Loading...