Troubleshooting 333

Troubleshooting Guide

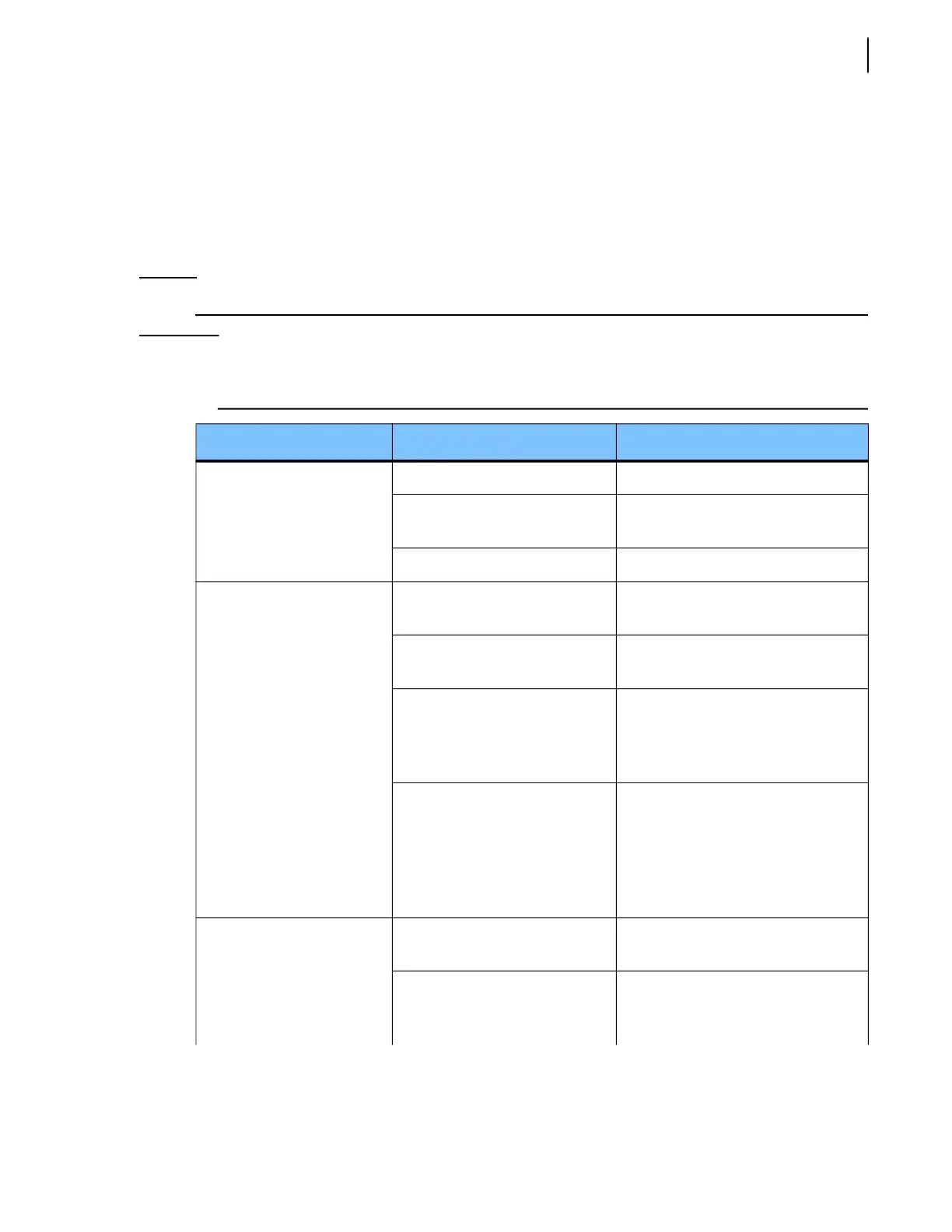

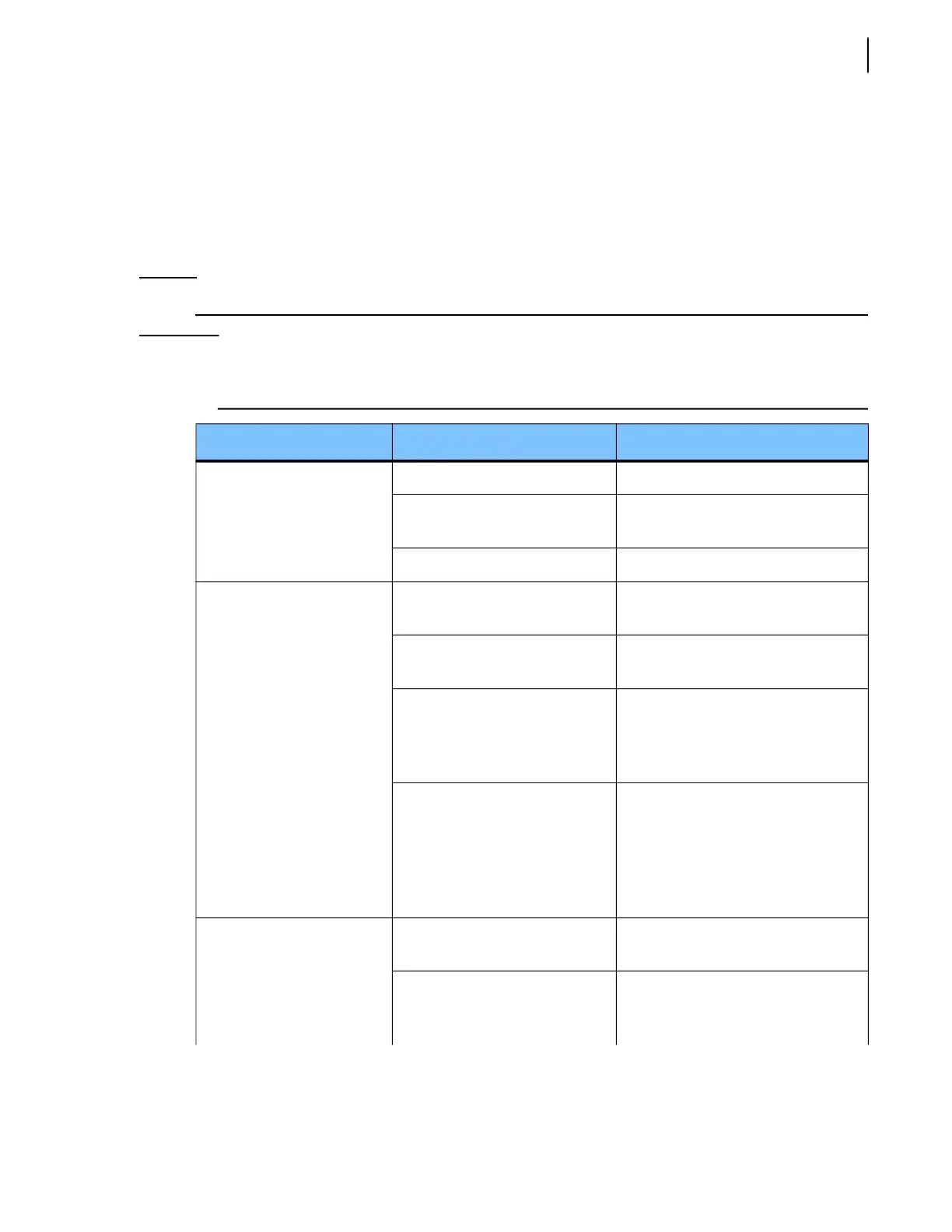

This troubleshooting guide will help identify the most commonly seen problems on the EXPERT™.

The table below will also provide the possible cause of the problem and give solutions to resolve that

problem.

For further information regarding customized options that might not be found in this

troubleshooting guide, contact LabriePlus.

NOTE: Only qualified staff must be allowed to perform troubleshooting tasks on the EXPERT™.

IMPORTANT: You must ensure that all safety features are properly maintained and all related procedures are

applied, such as the lockout/tagout procedure (see Locking Out and Tagging Out the Vehicle on

page 14).

Problem Possible causes Solution

Insufficient packing ratio Low oil pressure See Hydraulic Pressures on page 288.

Packer hydraulic cylinders

internally bypassing

See Detecting Cylinder Internal Leaks

on page 285.

Defective pump Replace the pump.

Overheating hydraulic oil

(temperature above 77°C

[180°F])

Low oil level in the hydraulic

tank

Add oil to the required level. See

Replacing Hydraulic Oil on page 283.

Hydraulic pressure too low or

too high

See Hydraulic Pressures on page 288.

Not the proper grade of oil

(that is too thin in hot

temperatures or too thick in

cold temperatures)

Change for oil indicated in

Recommended Lubricants on

page 235 (see Emptying Hydraulic

Tank on page 280).

Contaminated oil Clean the strainer and change the

return filter element. Fill with clean

oil. See Cleaning Strainer on

page 280, Replacing Filter Elements

on page 282, and Replacing

Hydraulic Oil on page 283.

Foaming oil Low oil level Add oil to the required level. See

Replacing Hydraulic Oil on page 283.

Air entering the system Tighten all hose and pipe

connections between the pump and

the hydraulic tank.

Loading...

Loading...