Lifting Arms 393

Adjusting the Arm Vane Pump Relief Valve

Usually, there is no arm vane pump relief valve on an EXPERT™. However, if your EXPERT™ vehicle is

equipped with such a valve, it would be located on the front of the pump.

Tighten the relief valve completely on the pump.

The arm (retract/extend) and gripper (up/down) operating pressures are the same as the main relief

valve. Table 1 lists the operating pressure and cycle time for each arm function. No adjustments are

required for these functions. Only “gripper close” requires proper adjustment to prevent crushing

roller carts. See Lubrication Chart and Hydraulic Schematic on page 415 to adjust the gripper load

sense relief valve.

For more information, see Adjusting Proportional Valve Pressure on page 292.

Bypassing a Dump Valve for Diagnostic Purposes

This procedure explains how to bypass the arm dump valve off of a front-mounted pump for an

E

XPERT™ side loader.

When arm cycle times and pressures are not able to be achieved, typically there are 2 components

that cause this: the dump (or recirculation) valve or the pump. The first step in troubleshooting is to

verify that the electrical system is operating correctly. If the dump valve is receiving proper power and

ground, causing the coil to magnetize, then we can continue with bypassing the arm dump valve.

Next step is to remove the dump valve all together and verify operation. If the arm operates with the

correct cycle times and pressures, then we can conclude that the dump valve is faulty and needs to be

replaced.

However, should the arm continue to have slow cycle times and low pressures, then the fault more

than likely is with the pump.

To bypass the arm pump dump valve on a front-mounted pump, apply this procedure:

1. The truck should be off and locked out/tagged out following all required procedures.

2. Relieve the air pressure from the hydraulic tank.

3. Close the ball valve (or shut-off valve) on the suction line, which is on the right side of the

hydraulic tank.

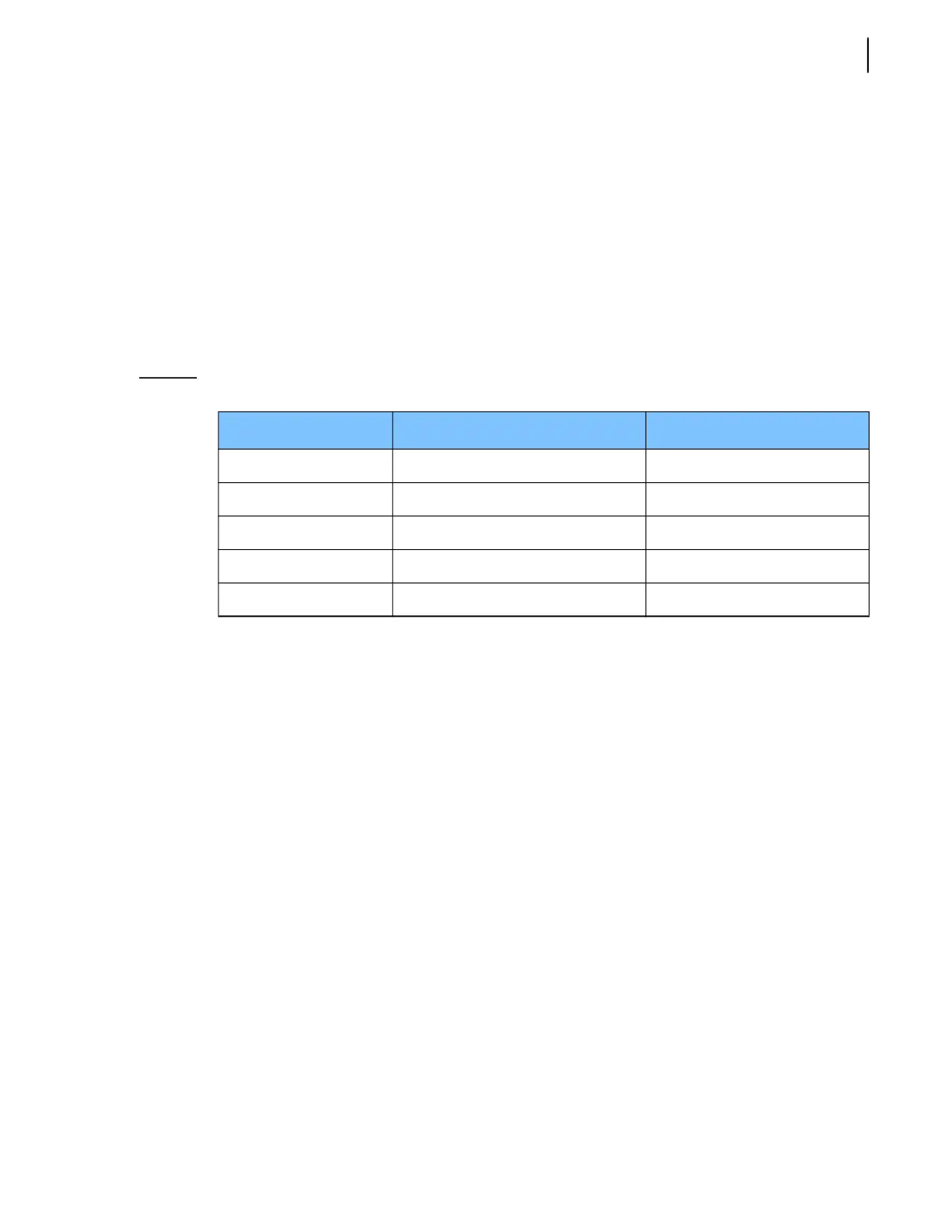

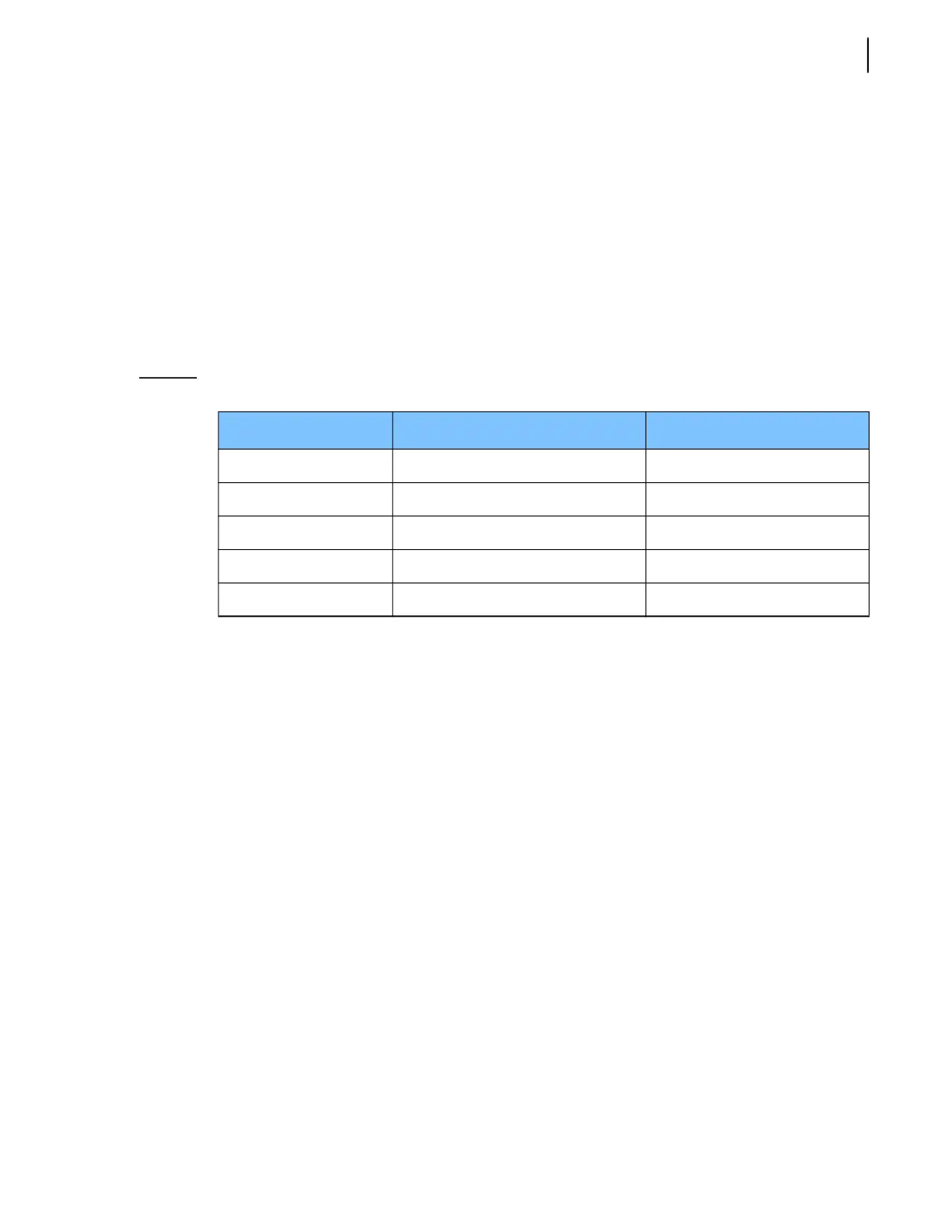

Table 1 Arm operating pressures and cycle times

Arm function Pressure setting (psi) Cycle time (sec.)

Extension/retraction 2000 2.8/4.2

Gripper up 2000 3.0

Gripper down 2000 3.0

Gripper close 1200 1.5

Gripper open 1200 1.8

Loading...

Loading...