Toe-In

Toe measurement is the angle between the vehicle

center line and the tire. The front wheels of the vehicle

should be adjusted for a slight inward alignment of the

forward edge of the wheels so they are closer together

at the front than at the back of the vehicle. This toe-in

adjustment improves steering and equalizes tire wear.

To make the toe-in adjustment:

1. Park the machine on level ground and straighten the

front wheels vertical with the grader boom frame.

2. Lower the moldboard enough to raise the front

wheels slightly, then block front axle.

3. Engage the park brake and turn off the engine.

4. Measure and mark the center of both front tires with

chalk or white marker.

5. Measure the distance between the marks on the

front tires.

6. Rotate tires so marks are at the rear and measure

the distance between the marks.

7. If the difference between the tire marks measured

front and rear is more or less than 1/8-inch (3.2 mm),

adjust the front tires by loosening the tie-rod jam

nuts. (Figure 5-7) Turn the wheels completely left

and right, checking for an obstructions or damaged

parts.

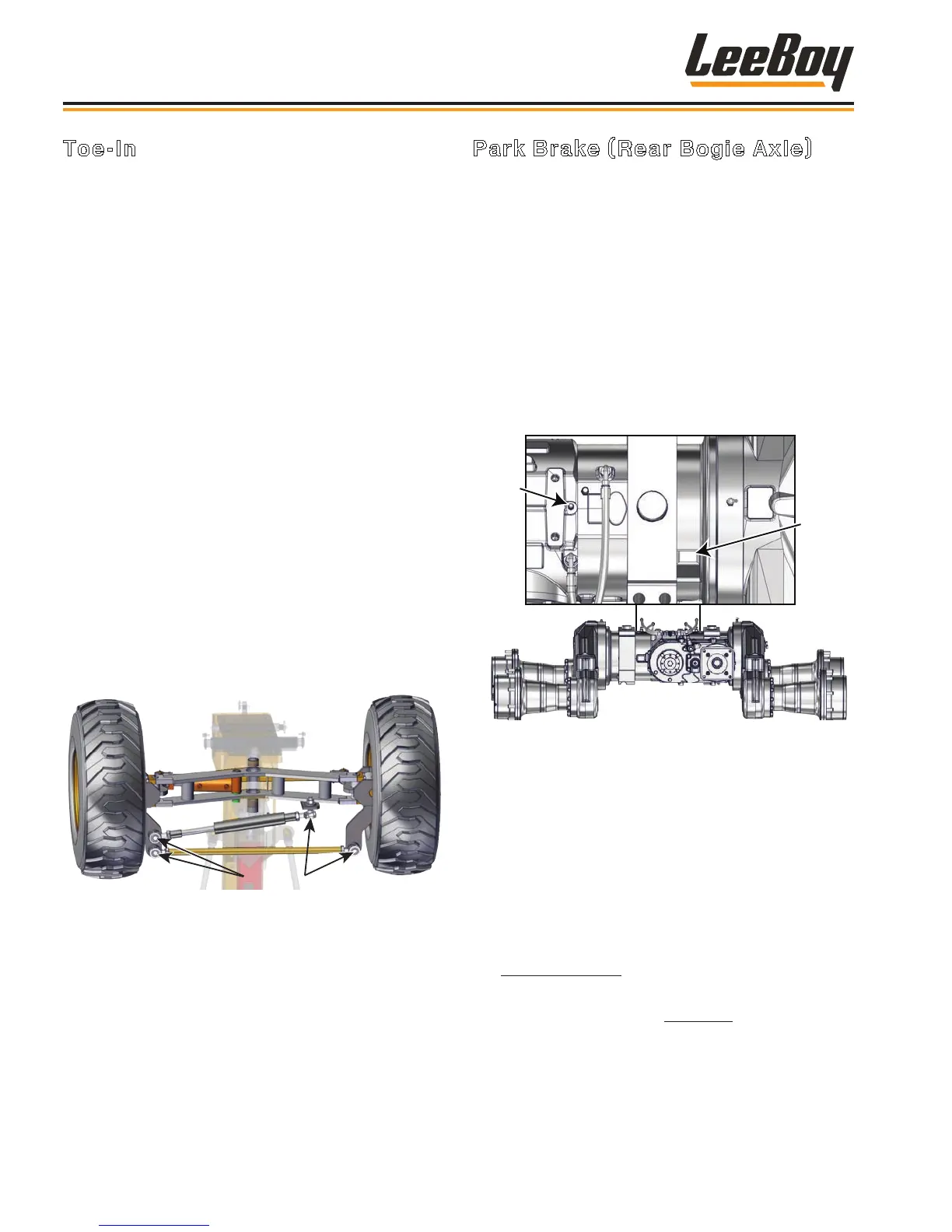

Tie Rods

Figure 5-7. Tie Rods

Park Brake (Rear Bogie Axle)

The park brake is used to hold the grader in position

while parked and may need adjustment due to wear and

extensive use. If you notice any slippage, adjustment is

needed.

Adjustment components are located on the top of

both sides of the front bogie axle. Use the following

procedure if the park brake needs adjustment:

1. Park the machine on a level surface, shut down the

engine and engage the park brake.

• Use the brake bleeder port to relieve pressure if

needed. (Figure 5-8)

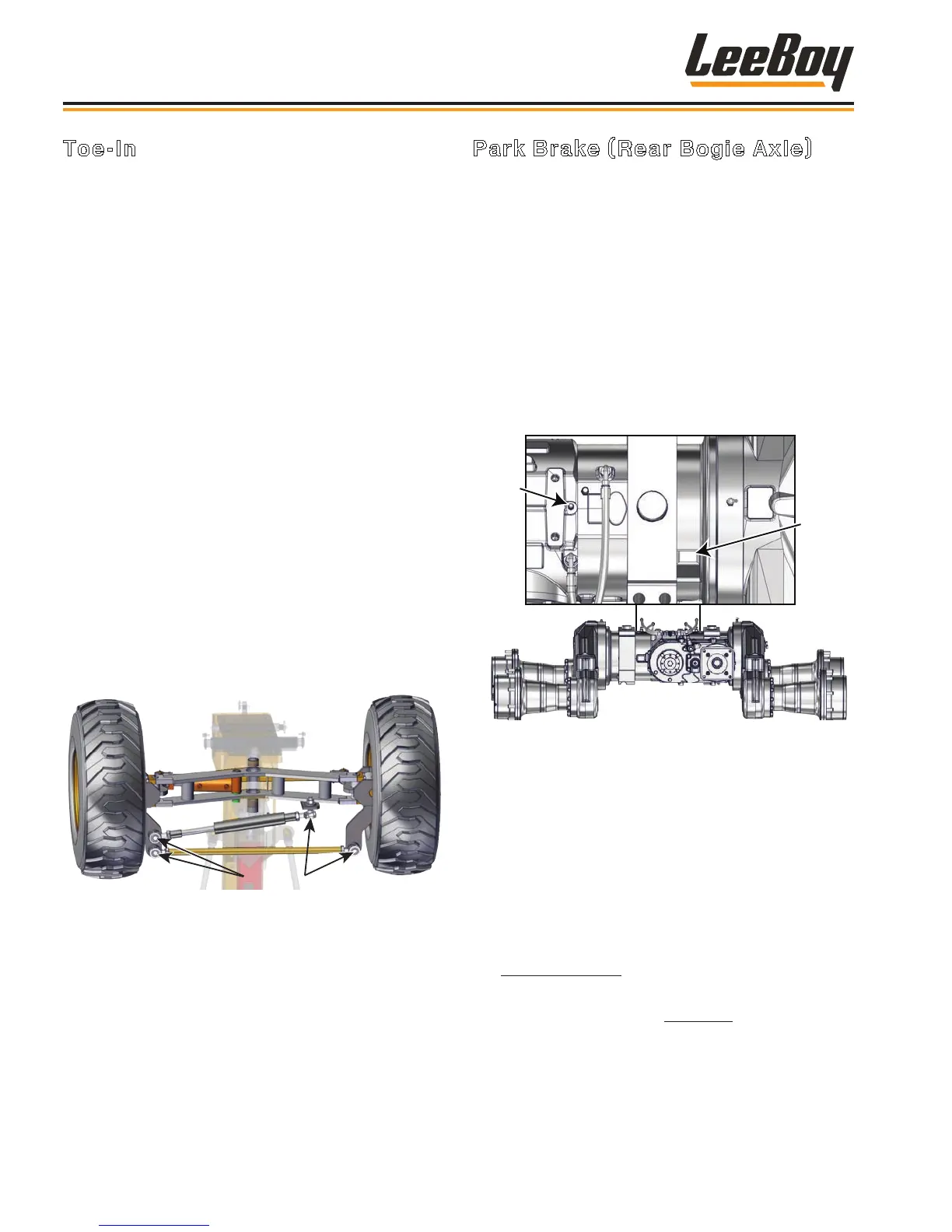

Brake

Bleeder

Adjuster

Screw

Front View

Figure 5-8. Park Brake Adjustment (Right Side

Shown)

2. The park brake adjustment screw is located in the

cavity just below and to the right or left (depending

on the side adjusting) of the bleeder port as shown

in Figure 5-8. Use a at-head screwdriver to

carefully remove the cavity cover.

3. Using a 13 mm wrench, loosen and remove the

bolt and retaining clip, which exposes the adjuster

screw.

4. Using a 14 mm wrench, turn the adjuster screw

counterclockwise until snug (5 - 6 ft lb), then mark a

at side of the adjuster screw.

5. Turn the adjuster screw clockwise ve (5) complete

turns.

6. Reinstall the bolt and retainer clip.

7. Repeat Steps 2 - 6 on the other side.

Maintenance

LeeBoy 685D Motor Grader5-12

Loading...

Loading...