Hydrostatic Drive

This grader is powered by a diesel engine with dual-

range, hydrostatic transmission system that propels

the machine forward or reverse at varying speeds with

dynamic braking action. Components of the hydrostatic

drive system include a hydrostatic traction pump,

variable-speed hydraulic motor, two-speed tandem axle,

rear axle carrier assembly and gear drive. A two-speed

transfer case mounted between the drive motor and

rear axle carrier provides high and low gear selection.

The rear axle carrier assembly converts input rotation to

axle shaft output rotation to drive the wheels.

The function and steering pump is mounted on the rear

of the traction pump and driven by the traction pump

output shaft. This provides hydraulic pressure and ow

to operate all the hydraulic cylinders that controls the

steering cylinder and other grader functions.

Electrical System

The electrical system is powered by two 12-volt

batteries, wired in parallel and mounted in a battery

compartment on the frame. Each battery produces

800 cold cranking amperes (CCA) for a total of 1600

CCA. An engine-mounted alternator with 135 amperes

of charging capacity keeps the batteries charged during

normal operation.

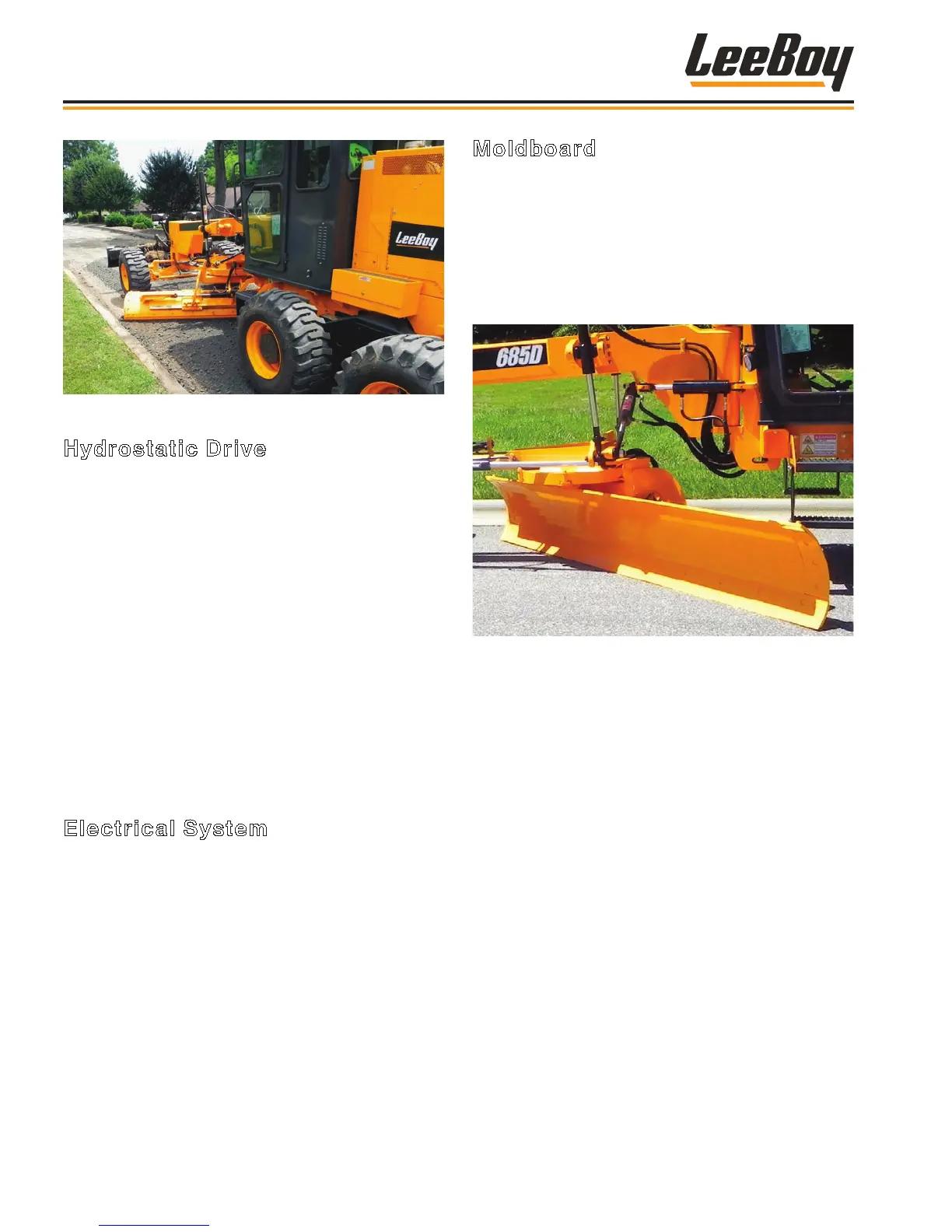

Moldboard

The moldboard is a major component of the 685D Motor

Grader. This adjustable, hydraulically-controlled blade

is mounted between the front and rear wheels that can

cut, move and spread materials to grade requirements.

The moldboard blade is mounted under the turntable

circle that can be hydraulically rotated right and left.

The moldboard height is controlled by two hydraulic

cylinders mounted to ball joints at a turntable.

The blade can be aggressively angled perpendicular

to the line of travel or parallel to the direction of travel.

The blade’s curved shape allows material to roll more

freely along the blade. The moldboard can be moved

forward and also shifts three (3) feet (.9 meters) left or

right. It can tilt side-to-side and front-to-rear, rotate

64 degrees, and features oat controls that can cut 1.2

feet (.355 meter) below grade. This versatility allows

extreme moldboard positioning to meet a variety of road

construction and maintenance needs, including easier

bank sloping and ditch cutting.

Components

LeeBoy 685D Motor Grader3-4

Loading...

Loading...